Application: Interior use, new wood, Baltic Birch Plywood with exposed edges.

Availability: First off I don't even know if I can get real varnish any more (Carver-Tripp is gone). All the stuff on the shelves looks like the exterior marine grade with UV protectant added. Special order for interior grade stuff, wait a week or do a couple hours of driving and burn some gas.

Why I like Varnish: gives wood a honey glow, some call it amber.

Why I don't like Varnish: the honey glow goes away after a few years, and the wood looks lighter, bleached out. Some call say it clouds. Also it may have a longer drying time.

...............................................

Why I like Polyurethane: I can get MinWax clear satin anywhere, anytime. It is supposed to be more stable color wise than Varnish and more durable.

Why I don't like Polyurethane: it gives wood a reddish hue (oil based stuff does this) and looks flat, dry or dead when compared to varnish (even the glossy does not have the same depth of sheen). It's plastic, right? Now your wood looks plastic or fake, and it feels different than varnish. Varnish has a natural smoothness, Polyurethane is more rubbery, not as hard shell like (guess it may not scratch or chip as easily?).

.............................................

I'm looking to hear from die hard fans of varnish.

I'm looking to hear from the converts who now swear by oil based polyurethane.

I'm looking to hear from those who have gone green and trust the water-born alternatives.

Old varnish/plywood project:

Availability: First off I don't even know if I can get real varnish any more (Carver-Tripp is gone). All the stuff on the shelves looks like the exterior marine grade with UV protectant added. Special order for interior grade stuff, wait a week or do a couple hours of driving and burn some gas.

Why I like Varnish: gives wood a honey glow, some call it amber.

Why I don't like Varnish: the honey glow goes away after a few years, and the wood looks lighter, bleached out. Some call say it clouds. Also it may have a longer drying time.

...............................................

Why I like Polyurethane: I can get MinWax clear satin anywhere, anytime. It is supposed to be more stable color wise than Varnish and more durable.

Why I don't like Polyurethane: it gives wood a reddish hue (oil based stuff does this) and looks flat, dry or dead when compared to varnish (even the glossy does not have the same depth of sheen). It's plastic, right? Now your wood looks plastic or fake, and it feels different than varnish. Varnish has a natural smoothness, Polyurethane is more rubbery, not as hard shell like (guess it may not scratch or chip as easily?).

.............................................

I'm looking to hear from die hard fans of varnish.

I'm looking to hear from the converts who now swear by oil based polyurethane.

I'm looking to hear from those who have gone green and trust the water-born alternatives.

Old varnish/plywood project:

I like the amber over reddish hue just to be clear.

I talked to "the wood guy" at the local hardware store (Stadium) who claims to spend most of his time at his real job ankle deep in wood shavings.

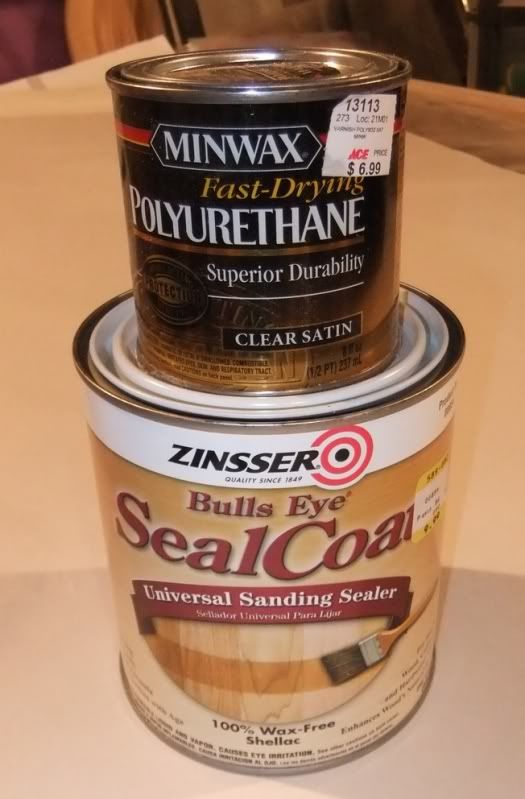

Per his suggestion I'm going to try a couple coats of sealer (alcohol based) and a top coat of oil based polyurethane. Theory has it that the sealer will give it that amber hue I like, but the sealer is sensitive to cleaners and chemicals and should be protected. That is were a top coat of polyurethane comes in.

He also warned me away from steel wool because over time residue may oxidize and discolor the wood. Suggested fine sandpapering between coats if I must (like a car finish).

One important factor I forgot is that 11 years ago when I built my own office furniture out of Baltic Birch plywood I did the varnishing at midnight in the office, and cracked open the windows. This project is being built in my basement, with a wife and cat in the home. The sealer smells a little like a good but sweet bourbon, and the polyurethane is mild compared to the fumes varnish puts out.

I've read at least one vote against Minwax as a brand, the shelves are full of other brands. Name a few you like better.

I'll post the test pieces in a few days.

This wood finishing is for my no-box loudspeaker experiment/prototype.

I talked to "the wood guy" at the local hardware store (Stadium) who claims to spend most of his time at his real job ankle deep in wood shavings.

Per his suggestion I'm going to try a couple coats of sealer (alcohol based) and a top coat of oil based polyurethane. Theory has it that the sealer will give it that amber hue I like, but the sealer is sensitive to cleaners and chemicals and should be protected. That is were a top coat of polyurethane comes in.

He also warned me away from steel wool because over time residue may oxidize and discolor the wood. Suggested fine sandpapering between coats if I must (like a car finish).

One important factor I forgot is that 11 years ago when I built my own office furniture out of Baltic Birch plywood I did the varnishing at midnight in the office, and cracked open the windows. This project is being built in my basement, with a wife and cat in the home. The sealer smells a little like a good but sweet bourbon, and the polyurethane is mild compared to the fumes varnish puts out.

I've read at least one vote against Minwax as a brand, the shelves are full of other brands. Name a few you like better.

I'll post the test pieces in a few days.

This wood finishing is for my no-box loudspeaker experiment/prototype.

Some guitar makers use Behlens Rockhard.

Rockhard Varnish

The 'sealer' you are using is shellac. If you make your own shellac solution by dissolving flakes in alcohol you can control the color by choosing different colors of flake shellac.

You are right to stay away from the exterior aka spar varnishes - too soft.

John

Rockhard Varnish

The 'sealer' you are using is shellac. If you make your own shellac solution by dissolving flakes in alcohol you can control the color by choosing different colors of flake shellac.

You are right to stay away from the exterior aka spar varnishes - too soft.

John

The Varathane brand of polyurethane is MUCH better than the Minwax: RustOleum.com

Dries faster and is quite a bit tougher.

Dries faster and is quite a bit tougher.

Parks Pro Poly

I made guitars for a few years and went through quite a few finish systems, including nitrocellulose lacquer.

I am rather impressed with the finish I used on my red oak floors. Most were original from 1955 but I took down three closets to make one larger room and had a lot of flooring to fit in...

I refinished the entire house with Parks Pro Polyurethane finish (satin). This was applied over some existing finish areas as well as raw wood.

This finish is quite hard. In order to get a good color match, I also finished the new red oak stair rails with the same stuff (so I'm touching it every day). It does not have that 'clammy, sticky' feel of typical indoor poly finish (ala Minwax) nor does it feel 'gummy' like the spar urethane either.

Here's the real kick: with the satin finish, you can control your gloss by how you mix it. The 'de-glosser' sinks to the bottom, and the gloss poly can be poured off the top. Then the rest can be mixed and added to the gloss you poured off to give just the right sheen.

In my case, I did two full wet coats and then sanded when dry before applying the third coat. Looks and feels great! (I used lamb's wool for the floors and just a good brush for the rails)

For exposed end grain, I suggest the minwax sanding sealer (yellow label).

Both the Parks Pro poly and Minwax sealer are available at Homo-Depot...🙂

I made guitars for a few years and went through quite a few finish systems, including nitrocellulose lacquer.

I am rather impressed with the finish I used on my red oak floors. Most were original from 1955 but I took down three closets to make one larger room and had a lot of flooring to fit in...

I refinished the entire house with Parks Pro Polyurethane finish (satin). This was applied over some existing finish areas as well as raw wood.

This finish is quite hard. In order to get a good color match, I also finished the new red oak stair rails with the same stuff (so I'm touching it every day). It does not have that 'clammy, sticky' feel of typical indoor poly finish (ala Minwax) nor does it feel 'gummy' like the spar urethane either.

Here's the real kick: with the satin finish, you can control your gloss by how you mix it. The 'de-glosser' sinks to the bottom, and the gloss poly can be poured off the top. Then the rest can be mixed and added to the gloss you poured off to give just the right sheen.

In my case, I did two full wet coats and then sanded when dry before applying the third coat. Looks and feels great! (I used lamb's wool for the floors and just a good brush for the rails)

For exposed end grain, I suggest the minwax sanding sealer (yellow label).

Both the Parks Pro poly and Minwax sealer are available at Homo-Depot...🙂

I have had good luck with Minwax Wipe-On Polyurethane (oil based) used according to the directions on the can. Dries crystal clear and builds to a nice depth in 4 to 6 coats.

I made guitars for a few years and went through quite a few finish systems, including nitrocellulose lacquer.

I'm assuming "nitrocellulose lacquer", was for a black piano like finish, right?

Have you used clear lacquer for any of your projects?

What does a company like Sonus Faber use for their wood finishes?

I like to kick it old-skool and use this stuff:

Dissolved in alcohol and then applied like a varnish.

Dissolved in alcohol and then applied like a varnish.

This is like a stain to get the honey/amber glow, right?Dissolved in alcohol and then applied like a varnish.

What do you put over it to protect the finish further?

This is like a stain to get the honey/amber glow, right?

What do you put over it to protect the finish further?

Actually it isn't, it's shellac. I forgot to mention it, sorry.

I don't put anything over it.

Really pleased with tung oil. Needs a little maintenance every few years if you don't varnish over it, but just so beautiful.

Just4Sheep

Just4Sheep

Really pleased with tung oil. Needs a little maintenance every few years if you don't varnish over it, but just so beautiful.

Just4Sheep

Wow yeah that's gorgeous.

I like to use boiled linseed oil from time to time.

If I can give you a tip: Try Howard's Feed 'n Wax as a maintenance cleaner/finish.

Full bodied shellac complete with the wax. Now that is bucking the trend of the herd.🙂Actually it isn't, it's shellac. I forgot to mention it, sorry.

I don't put anything over it.

I picked up some real varnish and real lacquer at an out of the way (for me) hardware store I was passing by.

More test strips are on the way.

The same store also has spray cans of both, but different brands.

Last edited:

Full bodied shellac complete with the wax. Now that is bucking the trend of the herd.🙂

I'm pretty sure the flakes in the pic are dewaxed.

Anyway, it's easy enough to separate most of the wax once you dissolve it up, if the flakes are not dewaxed.

And, if you want a bit of a challenge, just use the shellac and FrenchPolish with it....plenty shiny.😉

I'm assuming "nitrocellulose lacquer", was for a black piano like finish, right?

No; I used catalyzed acrylic urethane for that. It's all in how you block and buff it more so than what composition you apply. I mixed my own 'stain' colors in nitro for sunburst finishes. It really isn't a stain so much as a tint. Method: clear/tint/clear/block&buff. This was handy in the event of an error- I did not waste 40 hrs of wood work and $100.00 in raw material- I could sand off the tint and re-tint without touching the base wood.😉

Have you used clear lacquer for any of your projects?

Of course! Nitro, Catalyzed acrylic urethane and (automotive) lacquer- but that was the worst. Took forever to dry and was too soft. Also another clear for a short time- PPG "system 2000" I think it was called. That was too thin and applying it was a bit of a bitch. It seemed that as soon as I got accustomed to another paint system, they would close it down and replace it with another due to environmental impact...

What does a company like Sonus Faber use for their wood finishes?

I don't know precisely; however I would expect a sanding sealer of some type (probably water based) and a (low VOC these days) catalyzed acrylic urethane like I was using. Possibly a water borne clear too. They are decent these days; The ones I used were not very good and never were used by me on an instrument. Although the newer "safer" C.A.U.'s really kind of suck- particularly the solid colors (but you are not interested in that anyway). Clears seem to be OK still.

[I have done a solid Daphne blue bass recently and a few of my pool cues in clear before that for recent history] Pic of the last cue I did attached.

Attachments

I did a test batch of lacquer and one of varnish at the same time. Less than 1-SQ. Ft. of surface material area, and after cleaning the brushes I had to leave the house. The fumes were that bad even after taking the cleaning rags outside.

The lacquer reminds me of model airplane dope I used to use on tissue paper covered balsa framed aircraft when I was a teenager. Cheap buzz but not the intended result.

The shellac sealer with a polyurethane top coat is almost as nice as what I can do with varnish alone, and that is close to lacquer without evicting every living thing from the house for several hours.

The lacquer reminds me of model airplane dope I used to use on tissue paper covered balsa framed aircraft when I was a teenager. Cheap buzz but not the intended result.

The shellac sealer with a polyurethane top coat is almost as nice as what I can do with varnish alone, and that is close to lacquer without evicting every living thing from the house for several hours.

I have an interior lacquer here that does not have the UV resistance that marine lacquer does but it has extra scratch resistance, I don't know what kind of lacquer it is exactly, but it's water-based which is awesome. No smell, dries more evenly and you can clean your brushes under the tap.

I love using shellac as well. It is easy to put on, comes in different tones, you can select the sheen you want and correct any problems without a fuss.

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- Wood Finishes