You have done [or will do!] an electronics project from scratch.

What is the most difficult or frustrating aspect?

making the PCB?

getting the parts?

the chassis and getting it to look good?

getting the right layout [in the chassis/cabinet/case]?

testing?

What is the most difficult or frustrating aspect?

making the PCB?

getting the parts?

the chassis and getting it to look good?

getting the right layout [in the chassis/cabinet/case]?

testing?

HaHa, I have trouble with all of those!! Probably the most frustrating part for me is deciding on which parts to buy. I tend to be too obsessive and think about it for ages. When I finally have decided I find that one of the parts is not available and then have to start looking again for a replacement.

This blog entry has some insights (altbeit rather verbose) into my problems 😉 http://www.diyaudio.com/forums/blogs/wintermute/119-problem-wanting-get-best-performance.html

Then doing the layout is probably the next biggest hassle (both of the board, note I only do verro board, I've not done my own pcbs) both of the board and of where every thing goes inside the chassis.

edit: oh and no, I haven't finished the project discussed in that blog entry 😉

Tony.

This blog entry has some insights (altbeit rather verbose) into my problems 😉 http://www.diyaudio.com/forums/blogs/wintermute/119-problem-wanting-get-best-performance.html

Then doing the layout is probably the next biggest hassle (both of the board, note I only do verro board, I've not done my own pcbs) both of the board and of where every thing goes inside the chassis.

edit: oh and no, I haven't finished the project discussed in that blog entry 😉

Tony.

Tony,

Thanks for sharing! I hear ya!

IF I might suggest..............

Sounds like you might be better off doing a kit. Then 'copy' the part* you would most want to upgrade or replace, and work on that - when that is done, then install into the kit. That way you having a working device while you debate parts, re-design the PCB, etc.

Ken

*ie for a pre-amp, 'copy' the power supply, or VU, or pre-amp board, or input/output jacks, or ....

Thanks for sharing! I hear ya!

IF I might suggest..............

Sounds like you might be better off doing a kit. Then 'copy' the part* you would most want to upgrade or replace, and work on that - when that is done, then install into the kit. That way you having a working device while you debate parts, re-design the PCB, etc.

Ken

*ie for a pre-amp, 'copy' the power supply, or VU, or pre-amp board, or input/output jacks, or ....

Last edited:

It is the larger holes in a metal chassis that drive me crazy. There are some shops in USA and UK and such that sell the metal 'stamps' that do a great job on making the larger holes [circular and square and rectangular] but the price deters me, although I do not have access to a drill press.

I use the crude method of drilling multiple holes, then breaking off the centre piece and grinding it smooth.

For smaller holes and to help with the layout, i use strips of [wide] masking tape. Make a layout on paper, then transfer it by eye to the masking tape. I find the masking tape helps hold the small drill bit in place until it digs in. I also do a pilot hole for the larger holes.

Gawd-forbid if I have to make a square hole.

I use the crude method of drilling multiple holes, then breaking off the centre piece and grinding it smooth.

For smaller holes and to help with the layout, i use strips of [wide] masking tape. Make a layout on paper, then transfer it by eye to the masking tape. I find the masking tape helps hold the small drill bit in place until it digs in. I also do a pilot hole for the larger holes.

Gawd-forbid if I have to make a square hole.

By far, the "mechanical" side , mainly the chassis, because of machinery needed.

It pays to become friendly with a sheet metal shop.

Then, if needed, "making it look good or Pro built".

Then, getting a *good* PCB layout.

It pays to become friendly with a sheet metal shop.

Then, if needed, "making it look good or Pro built".

Then, getting a *good* PCB layout.

Hi Ken, I've done a few kits, the problem this time was it was completely my own design, which made it even worse 🙄

I will get there in the end, it just might take a while 😉 I do have pretty much all the parts, I need to do a layout for the active crossover part of the project and that I've been having difficulty getting motivated on. I did try to get going again recently but other things got in the way.

It doesn't help having multiple projects either....

Tony.

I will get there in the end, it just might take a while 😉 I do have pretty much all the parts, I need to do a layout for the active crossover part of the project and that I've been having difficulty getting motivated on. I did try to get going again recently but other things got in the way.

It doesn't help having multiple projects either....

Tony.

... I've been having difficulty getting motivated on.

I find I have to be in the right frame-of-mind, else I make a mess of things...

But project workshop is by the front-door so it helps to give me a push as I have to see every time I enter

Designing and fabricating a professional-looking chassis has stalled me many times. Getting good heatsinks for a power amp project is not easy, either.

I started a prototype chassis for my first tube amplifier, but made mistakes or overlooked details that I wished I had considered before cutting metal. I have access to a drill press now, so that's some help.

One of these daze I've got to learn how to use a PCB design program. Ought to be something for designing sheet metal, too.

I started a prototype chassis for my first tube amplifier, but made mistakes or overlooked details that I wished I had considered before cutting metal. I have access to a drill press now, so that's some help.

One of these daze I've got to learn how to use a PCB design program. Ought to be something for designing sheet metal, too.

I tried using different PCB program but found doing it by hand is faster. I also realized that for one-offs there is no point.

Maybe try Visio for sheet metal layout?? But again I think paper and pencil work better for one-offs.

Maybe try Visio for sheet metal layout?? But again I think paper and pencil work better for one-offs.

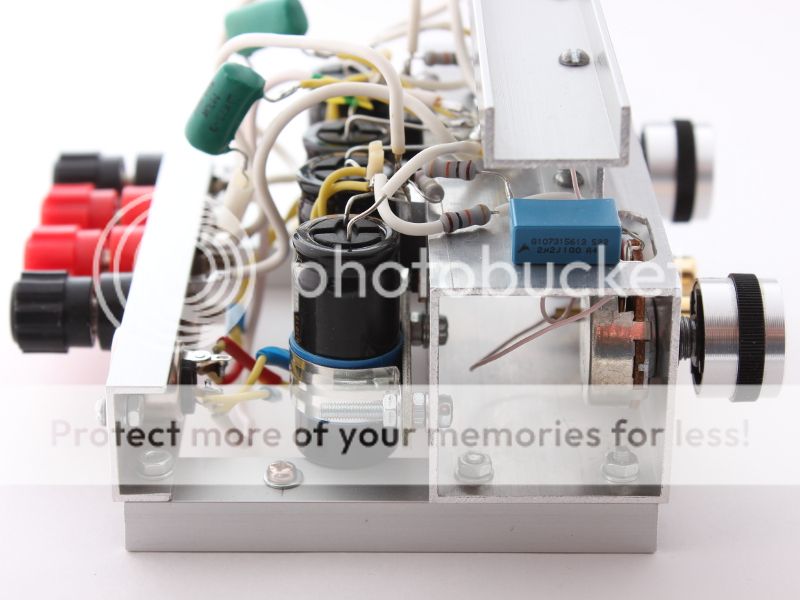

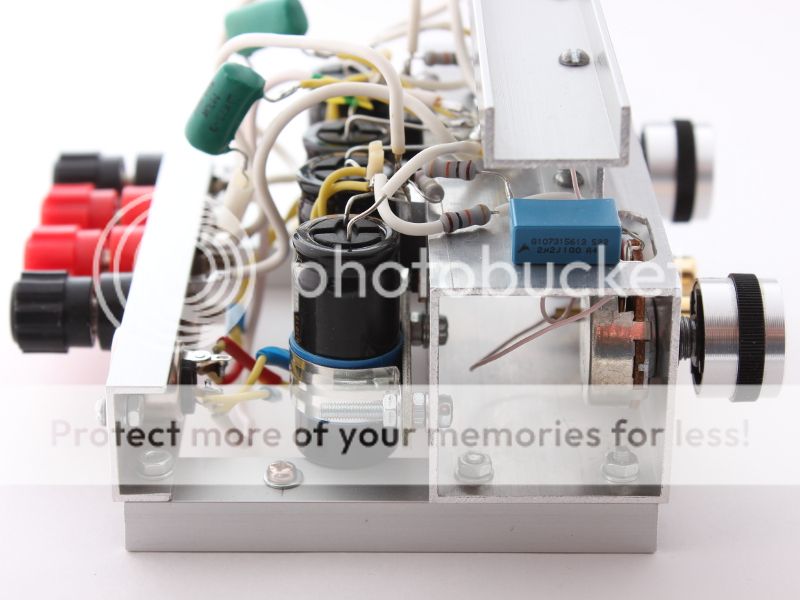

For inspiration look at EZAVALLA's handmade chassis (with limited access to a shear and folder)

and FROMTHECROWD's "non chassis" made out of standard "window extrusions":

Both quite inspiring:

The whole thread lives at: http://www.diyaudio.com/forums/chip-amps/79303-chip-amp-photo-gallery-235.html

Be sure to check it, it's full of interesting ideas.

and FROMTHECROWD's "non chassis" made out of standard "window extrusions":

Both quite inspiring:

The whole thread lives at: http://www.diyaudio.com/forums/chip-amps/79303-chip-amp-photo-gallery-235.html

Be sure to check it, it's full of interesting ideas.

Thank you Mr. Fahey for showing here my humble chassis. 😎

Just as an idea I leave a schematic to show how easy it is to build a chassis.

Take for sure you can add as many "beautiful things" as you want, but that layout is the simplest one I've found, even if you fold the sheets by hand 😱 ...

Just as an idea I leave a schematic to show how easy it is to build a chassis.

Take for sure you can add as many "beautiful things" as you want, but that layout is the simplest one I've found, even if you fold the sheets by hand 😱 ...

Attachments

Just as an idea I leave a schematic to show how easy it is to build a chassis.

...

I DO appreciate the "blue-print" but saying "how easy" makes me balk. For me Math is easy...............yet others recoil at the mere mention.

To do a 'proper' job, one [I would think] would need an excellent cutting tool [certainly not a hack-saw!], bending tool[I shudder at the thought of doing it by hand], files for removing blurs and rough edges, and the right material !

Not forgetting that getting all the parts to fit 'exactly' can be frustrating.

Then drilling the holes [aligned!!] to keep the thing together.

Then de-grease, and finish.

Last edited:

Nice chassis .... but I agree with KMossman (well, except about the math) in finding metal work difficult. Woodwork, no problem, as I have a complete shop, but metal ....

Case work for me! Although I bartered for a small drill press and that has helped tremendously. Still the metalwork is daunting to say the least. I sometimes think of picking up a small brake for the bending part, but am stymied on a reasonable way to cut it.

Nice chassis .... but I agree with KMossman (well, except about the math) in finding metal work difficult. Woodwork, no problem, as I have a complete shop, but metal ....

Math is EASY! [he smirks]

I totally aced drafting, electrical, woodwork, and metalwork [and Math!] in high school. [the metalwork teacher handed me a book and video, and said, "Teach yourself welding!", after I finished all the projects 4 classes ahead of the others].

BUT! I MUCH prefer to work with wood.

Case work for me! ........... for the bending part, but am stymied on a reasonable way to cut it.

A CNC industrial laser? A CNC plasma cutter? A 10 ton metal cutter?

Beats me too!

making the PCB?

I get them made in China very cheaply.

getting the parts?

Next day delivery.

the chassis and getting it to look good?

Cutting accurately is quite hard.

getting the right layout [in the chassis/cabinet/case]?

No problems if the chassis is big enough.

testing

So long as you are thorough there should be no problems.

I get them made in China very cheaply.

getting the parts?

Next day delivery.

the chassis and getting it to look good?

Cutting accurately is quite hard.

getting the right layout [in the chassis/cabinet/case]?

No problems if the chassis is big enough.

testing

So long as you are thorough there should be no problems.

making the PCB?

1) I get them made in China very cheaply.

getting the parts?

2)Next day delivery.

the chassis and getting it to look good?

3) Cutting accurately is quite hard.

getting the right layout [in the chassis/cabinet/case]?

4) No problems if the chassis is big enough.

testing

5) So long as you are thorough there should be no problems.

1) can you share the details? PM perhaps?

2) same day if I am not lazy

3) toooooooooo true

4) hahhahahhahaha indeed

5) yes, but it can get very tedious.............test, change, re-test, add, test again, modify, test, final text, oh DAMN!, test, change, re-test

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- What is the most difficult part of 'scratch' building for you?