I have a friend for whom weight is critical in terms of lifting. This led me to question the total weight of many tube amps. There are ways of cutting down weight like SMPS supplies, but one thing that interests me is ABS boxes. We are all familiar with the useful range of smaller ABS boxes but I don't remember anything larger until I came across these 1U, 2U and 3U ABS chassis available in black or grey. Very cheap too!

https://cpc.farnell.com/pro-power/g17082ubk/case-19-abs-2u-black-anti-static/dp/EN85543

My idea would be to add a 2mm SAA anodised aluminium top plate which would earth the components connected to it. I question, though, whether anodising would affect earthing, in which case a plain or "mill" aluminium top plate would be better. An anodised front plate could be added for looks.

This ABS chassis looks like a quick and cheap way of making a tube amp.

Thoughts?

https://cpc.farnell.com/pro-power/g17082ubk/case-19-abs-2u-black-anti-static/dp/EN85543

My idea would be to add a 2mm SAA anodised aluminium top plate which would earth the components connected to it. I question, though, whether anodising would affect earthing, in which case a plain or "mill" aluminium top plate would be better. An anodised front plate could be added for looks.

This ABS chassis looks like a quick and cheap way of making a tube amp.

Thoughts?

I looked at the data sheet, but there's no indication of temperature ratings. I'd make sure there's lots of ventilation. Size up to put plenty of space around heat generating parts like tubes/valves and power resistors.

Also, you'd want to make sure the ABS chassis doesn't flex too much and possibly crack from the weight of heavy parts like transformers and chokes.

That's all I can think of.

Also, you'd want to make sure the ABS chassis doesn't flex too much and possibly crack from the weight of heavy parts like transformers and chokes.

That's all I can think of.

Why on Earth would he need lifting it? 😕I have a friend for whom weight is critical in terms of lifting.

It looks like a toy to me, besides those flimsy mounting ears will crack when you mount it in a rack case.

It will stand NO weight whatsoever, beyond a couple ounces PCB with a Bluetooth receiver or similar featherweight product inside.

Probably you don´t men to rackmount it, but that is not the main point.

If a manufacturer makes such an impossible to use product (rack case) and a supposedly "serious" seller offers them without a ton of caveats or disclaimers, hinting they may very well replace a metal one, then they are both cheating the unwary.

Now IF they sold the exact same case, without those ridiculous mounting ears, without even mentioning the word "rack", then it would be complletely different.

Now, as is .... 😱

Besides, a 2mm x 205mm x 432mm aluminum plate will weigh 472 grams, more than a pound, almost half a kilo.

Same size 1mm CRS steel sheet will weigh 695 grams, so using aluminum saves 223 grams, half a pound.

Considering Transformer weight, doesn´t look like a good enough deal.

If anything, get a regular chassis, only made of Aluminum, and build amp there.

Why on Earth would he need lifting it? 😕>>

I can think of a few medical reasons like hernias, or simply getting older and finding it harder to lift stuff on and off the workbench and into your music rack.

<< Probably you don´t mean to rackmount it, but that is not the main point.

Now IF they sold the exact same case, without those ridiculous mounting ears, then it would be completely different.>>

Yes, that's true. I doubt if you could rack mount any weight with this, but as you say, that's not my intention. I prefer aluminium to steel for a few reasons, so I'm fine with adding a top plate to increase the stiffness under transformers. 2mm alu should be enough in a sandwich with the ABS, but one could go to 3mm.

<< If anything, get a regular chassis, only made of Aluminum, and build amp there.>>

I do that already with 2U rackmount parts

ABS softens at a pretty low temperature, then can catch fire, flame retardant grades have toxic additives.

Long term heat exposure should be less than 70 degrees C, you do not see much ABS in cars these days.

Not recommended for tube amps.

Stick to light weight metal, expanded metal or whatever.

Long term heat exposure should be less than 70 degrees C, you do not see much ABS in cars these days.

Not recommended for tube amps.

Stick to light weight metal, expanded metal or whatever.

Last edited:

Hello,

Personally I would be nervous in not having high voltages secured inside a fully grounded case for safety reasons. But hey, who wants to live forever?

Personally I would be nervous in not having high voltages secured inside a fully grounded case for safety reasons. But hey, who wants to live forever?

Hello,

Personally I would be nervous in not having high voltages secured inside a fully grounded case for safety reasons. But hey, who wants to live forever?

Well, that just means double insulated.

The fast majority of equipment and appliances work that way.

No ground wire needed.

My thoughts.

I don't really understand why you're looking for saving weight this way?

Of any tube amp, the power transformer as well as the output transformers are by far the heaviest.

Just use an aluminum chassis, they don't way much at all.

Compared to ABS, that difference will be very insignificant.

I don't really understand why you're looking for saving weight this way?

Of any tube amp, the power transformer as well as the output transformers are by far the heaviest.

Just use an aluminum chassis, they don't way much at all.

Compared to ABS, that difference will be very insignificant.

Hello,

Yes, double insulated is good. But most such devices you mention do not have anything like such high voltages. You are free to do it anyway you want, but personally safety matters to me and the rest of my family that would be using it.

Greg

Yes, double insulated is good. But most such devices you mention do not have anything like such high voltages. You are free to do it anyway you want, but personally safety matters to me and the rest of my family that would be using it.

Greg

Hello,

Yes, double insulated is good. But most such devices you mention do not have anything like such high voltages. You are free to do it anyway you want, but personally safety matters to me and the rest of my family that would be using it.

Greg

Yes they do, it's called mains voltage (up to around 380Vdc in SMPS) , which need (by regulations and standards) much higher safety precautions than anything that is secondary.

If personal safety matters so much to you, I would highly recommend diving a bit more into the IEC/NEN/UL standards.

When reading those you'll actually find and read that in some cases a ground/earth wire can actually do more harm than good.

Last edited:

Old CRT TV's were "double insulated", sometimes made from wood, and they were not grounded. 27kV seems like a high voltage to me. I never heard of any problems of people dying from them.

Anyhow ABS can be strong. Look at typical wastewater pipes in houses and try to break one. Aluminum plate is strong, foil isn't. It all depends on how thick the material is, right?

Agreed though, I don't even like using nylon hardware in a tube amp, and I would use a metal chassis.

As someone else said, the heavy parts are the coils. The chassis is only about 5% of the overall weight in my builds and I use steel. If the amp weights 25kg, is it really important to save 1kg?

Anyhow ABS can be strong. Look at typical wastewater pipes in houses and try to break one. Aluminum plate is strong, foil isn't. It all depends on how thick the material is, right?

Agreed though, I don't even like using nylon hardware in a tube amp, and I would use a metal chassis.

As someone else said, the heavy parts are the coils. The chassis is only about 5% of the overall weight in my builds and I use steel. If the amp weights 25kg, is it really important to save 1kg?

Last edited:

I'm just dealing with a similar situation, having fractured my humerus at the end of August, and I can confirm that at the moment, handling a typical valve amp requires planning. But, as already mentioned above, the chassis itself is the least of the worries. The transformers are.

I even delayed fitting the second OPT to my build to make it easier to handle while tuning things on one channel.

I even delayed fitting the second OPT to my build to make it easier to handle while tuning things on one channel.

Attachments

Find a workshop tool trolley, and adapt it as a wheeled support.

No need to lift it.

Use metal frame for the thing.

And why do you want to lift it?

Occasionally, you can always ask somebody, or is it going to be traveling from gig to gig?

Long term ESCR of ordinary ABS is about 70 degrees, you don't see that much heat in Canada. But in a tube amp, maybe.

ESCR is a long term life description test, Environmental Stress Cracking Resistance.

No need to lift it.

Use metal frame for the thing.

And why do you want to lift it?

Occasionally, you can always ask somebody, or is it going to be traveling from gig to gig?

Long term ESCR of ordinary ABS is about 70 degrees, you don't see that much heat in Canada. But in a tube amp, maybe.

ESCR is a long term life description test, Environmental Stress Cracking Resistance.

Last edited:

My thoughts?I have a friend for whom weight is critical in terms of lifting. This led me to question the total weight of many tube amps.

This ABS chassis looks like a quick and cheap way of making a tube amp.

Thoughts?

Use an Aluminum chassis.

The weight is likely similar or less than ABS, but it's much stronger.

You may also find that continued heat cycling combined with UV exposure will render the plastic brittle and liable to crack, even if it originally started out as strong enough to carry the weight demanded of it, it may not cope a few years later.

You also need to consider the glass transition temperature of the material - it may start to creep locally in places where it is exposed to high temperature.

kind regards

Marek

You also need to consider the glass transition temperature of the material - it may start to creep locally in places where it is exposed to high temperature.

kind regards

Marek

Use ready to fix aluminum sections, there are many varieties that let you use screws.

Make a space frame, and use wire mesh as finger guards.

Thanks, MarekH, for making my point a little clearer.

Make a space frame, and use wire mesh as finger guards.

Thanks, MarekH, for making my point a little clearer.

Last edited:

There are pictures here in DIY Audio galleries showing beautiful and very creative chassis ideas built out of Aluminum extrusions bolted/riveted together plus some flat aluminum sheet.

Look around for ideas, you´ll be surprised.

Look around for ideas, you´ll be surprised.

I have a friend for whom weight is critical in terms of lifting. This led me to question the total weight of many tube amps. There are ways of cutting down weight like SMPS supplies, but one thing that interests me is ABS boxes. We are all familiar with the useful range of smaller ABS boxes but I don't remember anything larger until I came across these 1U, 2U and 3U ABS chassis available in black or grey. Very cheap too!

https://cpc.farnell.com/pro-power/g17082ubk/case-19-abs-2u-black-anti-static/dp/EN85543

My idea would be to add a 2mm SAA anodised aluminium top plate which would earth the components connected to it. I question, though, whether anodising would affect earthing, in which case a plain or "mill" aluminium top plate would be better. An anodised front plate could be added for looks.

This ABS chassis looks like a quick and cheap way of making a tube amp.

Thoughts?

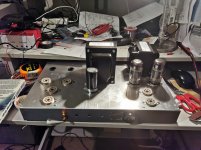

I have this case holding a SS preamp. I was looking for something cheap and easy with rack ears and for the most part it satisfied those requirements. It's very flimsy.

For rack usage, it's not a great design. The force necessary to flip down a toggle switch is enough to cause the chassis to spread apart. I ended up riveting the rack ears to the bottom clamshell to prevent this. For table top usage, this isn't an issue.

Another issue is the position of the four screws that hold the whole assembly together. They are placed somewhat inboard and can be slightly annoying to work around when placing components.

Given the weight of the other components, I don't see an ABS chassis like this having any significant weight advantage over the classic wooden box with metal top plate. Or go with a Hammond steel or aluminum chassis which can be paired with a matching cage if desired.

The other elephant in the room is fire risk, or rather what happens next.

Wooden and metal items are quite difficult to ignite and the fumes although irritating to the eyes and nose, still let you walk away. With synthetic materials like plastics or resins, the fumes can be so toxic that you will instantly wretch, your eyes will sting shut and you will literally be incapacitated on the spot. It has happened to me once and I was stunned that I almost didn't make it the two yards to the outside door - the shock of inhaling the fumes was that great.

Natural materials have a much safer failure mode.

kind regards

Marek

Wooden and metal items are quite difficult to ignite and the fumes although irritating to the eyes and nose, still let you walk away. With synthetic materials like plastics or resins, the fumes can be so toxic that you will instantly wretch, your eyes will sting shut and you will literally be incapacitated on the spot. It has happened to me once and I was stunned that I almost didn't make it the two yards to the outside door - the shock of inhaling the fumes was that great.

Natural materials have a much safer failure mode.

kind regards

Marek

- Home

- Amplifiers

- Tubes / Valves

- Using ABS chassis for tube amps?