A little project I have going is to restore this UA 1016 preamp to working condition.

The UA 1016 is a nice transformer coupled fully differential 2 stage preamp that uses a 12AX7 and a 12BH7. It is capable of +30dBm output - 1 watt - and can be configured up to 50 dB open loop gain.

These were used in the early UA recording desks, ca. UA 610 era, that were used in some of the first multi channel and multi track studios in the early 1960s. It could be configured as a mic amp, line amp, or summing amp. I'm not sure how there were used with an actual 610 desk.

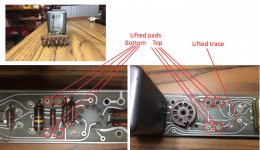

The issue is that there were some huge leads jammed into the coupling cap holes. The caps should be .047/400 (originals are tall cylindrical Sprague .047/600 with radial leads, maybe paper + oil) so I'm guessing some well intentioned but technically inept person tried to put 400V orange drops in there :-( then got frustrated and tried to remove them. Anyway the pads are mostly gone and the fiberglass is obviously stressed. A trace is also lifted part way back to its origin.

I'm considering putting Xicon .047/400 MPP ("brown drop") caps in which are very close to the same lead spacing and have regular diameter leads.

I'm thinking of installing eyelets for this repair, using the Keystone kit. I can probably super glue the lifted trace back down after cleaning all the solder off it.

The existing (larger) eyelets are for the filter caps, which I will replace with 33/450 electrolytics in place of the original 2-section cap.

Any other ideas?

The UA 1016 is a nice transformer coupled fully differential 2 stage preamp that uses a 12AX7 and a 12BH7. It is capable of +30dBm output - 1 watt - and can be configured up to 50 dB open loop gain.

These were used in the early UA recording desks, ca. UA 610 era, that were used in some of the first multi channel and multi track studios in the early 1960s. It could be configured as a mic amp, line amp, or summing amp. I'm not sure how there were used with an actual 610 desk.

The issue is that there were some huge leads jammed into the coupling cap holes. The caps should be .047/400 (originals are tall cylindrical Sprague .047/600 with radial leads, maybe paper + oil) so I'm guessing some well intentioned but technically inept person tried to put 400V orange drops in there :-( then got frustrated and tried to remove them. Anyway the pads are mostly gone and the fiberglass is obviously stressed. A trace is also lifted part way back to its origin.

I'm considering putting Xicon .047/400 MPP ("brown drop") caps in which are very close to the same lead spacing and have regular diameter leads.

I'm thinking of installing eyelets for this repair, using the Keystone kit. I can probably super glue the lifted trace back down after cleaning all the solder off it.

The existing (larger) eyelets are for the filter caps, which I will replace with 33/450 electrolytics in place of the original 2-section cap.

Any other ideas?

Attachments

Last edited:

I can't argue with eyelets. Worked for Fender. Rather than mess with tired traces, I'd be inclined to wrap fine wire where the eyelet will be and run it over to where it should go. This will more than double the number of repairs that can be attempted over the preamp's life.

For the smaller holes what about a pin receptacle? You can get short open bottom ones that press fit.

That's awful fancy. Fender used shoe eyelets. USM (United Shoe Machinery) made eyelet making machines in all sizes, not just for shoes.

A current source(*) --

Tall eyelets for .125 inch board

Short eyelets for Black Fiberboard

They are installed similar to the Turret Lugs, see how-to link.

Yes, for one repair it does not matter much how fancy (expensive) you go. However it appears the board in Michael's hand already has shoe-type eyelets.

(*) Disclosure: I know this guy, have bought from him, he ships quick, but does not give me any kickback to plug his store. There are other vendors.

Last edited:

Well, no argument from me. Michael was asking for other ideas and my first thought was the shoe eyelets were a bit big for a 0.6mm cap lead. Checking mouser though I see there are smaller eyelets. I don't know that the recepts are any fancier than the eyelet though easier to press in.

I have the pin sockets on hand (no staking tools for eyelets) and would run the trace or fine wire to the not yet completely set receptacle, (if wire, wrap it around a <100% turn) and then press the flange down to the board for a neat finish.

I have the pin sockets on hand (no staking tools for eyelets) and would run the trace or fine wire to the not yet completely set receptacle, (if wire, wrap it around a <100% turn) and then press the flange down to the board for a neat finish.

Thanks!

I had these from some other project that seem to be just about the right size. I just bought 100 at the time thinking it couldn't hurt... Also managed to decide to keep them through the Great Purge of 2013-2014. One of those times it worked out.

I can use some 30 gauge kynar insulated wire and rework adhesive to replace the lifted trace, but will need to be careful not to pinch it under the eyelet when I stake it in place. The wire could be soldered around the outside edge of the eyelet I guess.

I had these from some other project that seem to be just about the right size. I just bought 100 at the time thinking it couldn't hurt... Also managed to decide to keep them through the Great Purge of 2013-2014. One of those times it worked out.

I can use some 30 gauge kynar insulated wire and rework adhesive to replace the lifted trace, but will need to be careful not to pinch it under the eyelet when I stake it in place. The wire could be soldered around the outside edge of the eyelet I guess.

Attachments

. The wire could be soldered around the outside edge of the eyelet I guess.

Could you fit a little solder in the underside of the outside edge/flange of the eyelet and once brought down on the trace and staked, heat the eyelet, like with tube base pins and caps? Just wondering.

- Status

- Not open for further replies.

- Home

- Live Sound

- Instruments and Amps

- UA1016 Preamp Restoration