Interesting mass loading system here by Avid. Solid Aluminium chassis, so costly but not difficult to replicate.

Anyone care to comment?

Avid Hifi Reference Four Loudspeakers | Hifi Pig

I wonder if this would do as good a job of dealing with back waves from the driver as open baffle, or stuffed transmission line designs like LXmini woofer, or Speakerworks Statement where they use open backed tubes to the mids?

Anyone care to comment?

Avid Hifi Reference Four Loudspeakers | Hifi Pig

I wonder if this would do as good a job of dealing with back waves from the driver as open baffle, or stuffed transmission line designs like LXmini woofer, or Speakerworks Statement where they use open backed tubes to the mids?

Attachments

Also an interesting way to support the driver magnet, I wonder why they don't just use a stronger chassis.

The Perspex sheets look like they provide some form of deviation in path/resistance to air movement between the driver and the port.

I presume that the black strips between the perspex and the cabinet wall act like a soft coupling, adding damped stiffness, I wonder what they're made of, something heavy like steel or flexible. Also, how the hell do they tighten up the bolts on the inside of the cabinets?.

Are the perspex baffles/stiffeners used in production, or just for the brochure pictures?

Are the perspex baffles/stiffeners used in production, or just for the brochure pictures?

I didn't read any indication the Perspex was part of the design..........

Right, the cab wall/damped brace is a 'token'/'nod' in lieu of full on constrained layer damping and assume they're part of its construction; at least I've done it in many industrial enclosure apps, so know it's worth the effort when the appropriate damping material is used for the intended app.

Apparently before mounting the bottom plate.

Right, the cab wall/damped brace is a 'token'/'nod' in lieu of full on constrained layer damping and assume they're part of its construction; at least I've done it in many industrial enclosure apps, so know it's worth the effort when the appropriate damping material is used for the intended app.

Apparently before mounting the bottom plate.

Interesting that many many speakers do just fine without a large “tuned” mass attached to the baffles.

Maybe I’ll try adding a chunk of steel to the baffles in my car doors and give it a listen.

I thought the angle of those internal deflectors might’ve been key to reducing reflections.

Maybe I’ll try adding a chunk of steel to the baffles in my car doors and give it a listen.

I thought the angle of those internal deflectors might’ve been key to reducing reflections.

They don't. That mass only works on a specific frequency and does nothing outside of that. The midrange stuff is reflected and goes back to the membrane and will be dispersed from it. Aside from that it's stupid to put a reflector exactly onto the end of the port.

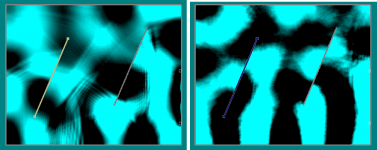

These sims show a couple of examples of the moving wave pattern each for with and without the reflectors. It's difficult to see much but the case with the reflectors has more fuzzy bits so perhaps a small reduction. I still wouldn't want to go without damping material unless I could measure an improvement.I wonder if this would do as good a job of dealing with back waves

Attachments

Also an interesting way to support the driver magnet, I wonder why they don't just use a stronger chassis.

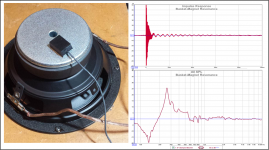

It's not so much about supporting the driver magnet as it is about damping the high-Q resonance of the mass-spring system (mass=magnet, spring=basket). An example accelerometer measurement attached, as well as an animated gif of the resonance mode. Most stamped basket woofers will have resonance in the 200-300Hz range...cast baskets usually in the 600-900Hz range. When fed with a sine tone at the resonance frequency, pretty much the entire enclosure is excited by it...easy to feel with the finger tips. The back usually most of all. An easy way to differentiate it from panel resonance modes is to look at response with accel mounted to a back corner of the enclosure. Any resonance you see there is from the basket-magnet resonance, not a panel mode.

Attached also is the AVID patent application as well as an approved patent from Genelec for essentially the same thing. The Genelec patent does have a bit of technical details.

An animation of the general damping concept can be seen here:

The Dynamic Vibration Absorber

Attachments

On some " magnet out " speakers I made, if I put a finger in the gap between the magnet and chassis, I could feel a vibration, I squashed some red cheese wax in the gap and in made a noticeable improvement to the sound, removing a " zing " it previously had. I think that soft cabinets ( like the BBC LS35a ) have the advantage of damping the magnet chassis baffle vibration, the Remlab sandwich is a good example of a baffle that can dampen such vibrations.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Tuned Mass Damping System