Hello everyone, long time lurker and admirer.

I picked up a functional S500 optical Bias with some cosmetic challenges. She lived a tough life in a car collectors shop. A lot of paint overspray and grime. Inside is not bad though. So I have been reading up on everything I can find concerning operating and servicing these babies. I have repaired a lot of Sansui, McIntosh and the like but this is my first class. A A/B amp. I know they run warm, 40-50c. My particular unit runs about 54c on the left and 50c on the right after idling for 30 min no load. I have only run it for 30 min a few times until I can give it a proper check up and maybe change the smaller caps where needed. I would like to get the units bias balanced as well as I can

I’m not quite sure on the biasing procedures, I know the pot for the bias adjustment is a turd to get to. I see on some schematics you set the bias cold to 90mV across one emitter where some have 20-40 mV as optimal. What temp would be best to bias it too? I’ve read some run cool and some run hot.

Can anyone enlighten me as to the proper procedure for the S500 with optical bias? Also has anyone recapped this model? I’m sure some are due to be changed out by now.

Thanks for any help.

Vince.

I picked up a functional S500 optical Bias with some cosmetic challenges. She lived a tough life in a car collectors shop. A lot of paint overspray and grime. Inside is not bad though. So I have been reading up on everything I can find concerning operating and servicing these babies. I have repaired a lot of Sansui, McIntosh and the like but this is my first class. A A/B amp. I know they run warm, 40-50c. My particular unit runs about 54c on the left and 50c on the right after idling for 30 min no load. I have only run it for 30 min a few times until I can give it a proper check up and maybe change the smaller caps where needed. I would like to get the units bias balanced as well as I can

I’m not quite sure on the biasing procedures, I know the pot for the bias adjustment is a turd to get to. I see on some schematics you set the bias cold to 90mV across one emitter where some have 20-40 mV as optimal. What temp would be best to bias it too? I’ve read some run cool and some run hot.

Can anyone enlighten me as to the proper procedure for the S500 with optical bias? Also has anyone recapped this model? I’m sure some are due to be changed out by now.

Thanks for any help.

Vince.

That is a very nice amp! Certainly worth going through and cleaning all of the overspray off.

So if you remove the rear panel, the bias pot should be facing towards the back. This is very handy as the back panel is relatively easy to set in place with a screw or two while you are letting the amp thermally stabilize. removing the top cover will move the bias readings more. It can be a bit sensitive.

The bias adjustment is sensitive. Basically you adjust it until the heatsinks are say 25-30C above ambient. It looks like you are pretty much there. There is a tantalum cap on the front end board that should be replaced with a film.

Check the DC offset. If it is below 50mV, then the amp is probably pretty healthy.

Don't worry too much about the mV across the emitter resistors.

For the most part, you shouldn't have to recap much on the amp. They were put together with quality parts. But with that being said, it is old. So if you want to just to be safe, then why not.

So if you remove the rear panel, the bias pot should be facing towards the back. This is very handy as the back panel is relatively easy to set in place with a screw or two while you are letting the amp thermally stabilize. removing the top cover will move the bias readings more. It can be a bit sensitive.

The bias adjustment is sensitive. Basically you adjust it until the heatsinks are say 25-30C above ambient. It looks like you are pretty much there. There is a tantalum cap on the front end board that should be replaced with a film.

Check the DC offset. If it is below 50mV, then the amp is probably pretty healthy.

Don't worry too much about the mV across the emitter resistors.

For the most part, you shouldn't have to recap much on the amp. They were put together with quality parts. But with that being said, it is old. So if you want to just to be safe, then why not.

Attachments

-

hfe_threshold_audio_sa_1_2_3_200_300_500.pdf1.1 MB · Views: 8

-

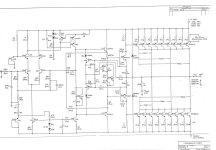

s2-3-500bias.jpg31.3 KB · Views: 32

s2-3-500bias.jpg31.3 KB · Views: 32 -

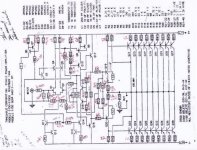

s150-300-500 schmatic.jpeg84.6 KB · Views: 34

s150-300-500 schmatic.jpeg84.6 KB · Views: 34 -

S300 with values.jpg613.8 KB · Views: 37

S300 with values.jpg613.8 KB · Views: 37 -

Tantelem capacitor.jpg42.3 KB · Views: 32

Tantelem capacitor.jpg42.3 KB · Views: 32 -

thresholdadjust.pdf199.1 KB · Views: 6

-

20211224_132106 2.jpg396.8 KB · Views: 29

20211224_132106 2.jpg396.8 KB · Views: 29

Thank you Mike, excellent info. This will come in handy.

When I initially checked offset it was 18mV left and 14mV right on start up, I did not check it warmed up. I don’t see a value for the trimmer on the schematic. Has anyone put a multi turn in there to smooth out the adjustments? I have some 0.15 Wima film caps I can replace the tantalum with. I spent several weeks cleaning off the overspray, the guy I bought it from thought it was rust pits so he pretty much sold it to me for parts. Turns out it was metallic Bronze, same color at the owners Corvette. The whole time he was showing me the amp I was thinking Aluminum does not rust, it was ugly though.

When I initially checked offset it was 18mV left and 14mV right on start up, I did not check it warmed up. I don’t see a value for the trimmer on the schematic. Has anyone put a multi turn in there to smooth out the adjustments? I have some 0.15 Wima film caps I can replace the tantalum with. I spent several weeks cleaning off the overspray, the guy I bought it from thought it was rust pits so he pretty much sold it to me for parts. Turns out it was metallic Bronze, same color at the owners Corvette. The whole time he was showing me the amp I was thinking Aluminum does not rust, it was ugly though.

The issue with single turn pots that haven’t been turned in awhile is air corrosion on the wiper trac and even though you might adjust

it to spec , the next time you measure it thru a heat cycle again you will find a different bias spec. than what you initially set it too.

Either get some spray cleaner in there beforehand and go full stop 10 times back and forth or better yet as you suggested

replace with a multi turn for finer adjustments

it to spec , the next time you measure it thru a heat cycle again you will find a different bias spec. than what you initially set it too.

Either get some spray cleaner in there beforehand and go full stop 10 times back and forth or better yet as you suggested

replace with a multi turn for finer adjustments

You can try R5 changed to 200R resistor and adding a 200R pot in series with it. However, 18mV adn 14mV are just perfect. I wouldn't touch that at all.

Now the bias, I personally like the amp's sound when it is running nice and toasty. So I would leave that as well. Honestly, just recap the EL caps on it and call it a day. If you would like, you can replace the trim pot with a multiturn. However, I personally think that it it s a nice feature that it faces towards the back. Pretty clever really. So if you can find a multiturn, that would face towards the back, that would be really neat.

Take note of the value that the pot is set to and match that if you can. It is basically a series resistor so two legs to one trace and one leg to another. So make a mark on the board and the trim pot to record it's orientation, remove the trim pot and measure the value of resistance and then match the new one to it paing mind to it's orientation. that should result in nearly the same bias. If you would like, you can reduce the bias beforehand so that once you install the new pot, you can adjust the bias.

These amps have drift in their biass. The bias compensation network is decent but set it and let it warm up. adjust, let the temp stabilize, adjust, stabilize and so on until you get to where you want to be.

Now the bias, I personally like the amp's sound when it is running nice and toasty. So I would leave that as well. Honestly, just recap the EL caps on it and call it a day. If you would like, you can replace the trim pot with a multiturn. However, I personally think that it it s a nice feature that it faces towards the back. Pretty clever really. So if you can find a multiturn, that would face towards the back, that would be really neat.

Take note of the value that the pot is set to and match that if you can. It is basically a series resistor so two legs to one trace and one leg to another. So make a mark on the board and the trim pot to record it's orientation, remove the trim pot and measure the value of resistance and then match the new one to it paing mind to it's orientation. that should result in nearly the same bias. If you would like, you can reduce the bias beforehand so that once you install the new pot, you can adjust the bias.

These amps have drift in their biass. The bias compensation network is decent but set it and let it warm up. adjust, let the temp stabilize, adjust, stabilize and so on until you get to where you want to be.

Looks like a top adjust multi turn Bourne’s trimmer would work nice and still face rear. I like to change trimmers on old gear as a matter of maintenance. Had one go open on a Sansui G8000 and burn up a lot of pieces.

Tomorrow I will re measure everything to get a baseline. Is bias increase CCW or CW? I still have a bit of cleaning and some rusty hardware to clean up.so far it’s looking better. The switch plate has some corrosion, hopefully I can find a replacement later on.

Tomorrow I will re measure everything to get a baseline. Is bias increase CCW or CW? I still have a bit of cleaning and some rusty hardware to clean up.so far it’s looking better. The switch plate has some corrosion, hopefully I can find a replacement later on.