Hi,

on all Thorens TP 14 tonearms I have seen, the tracking force balancing weight is sagging. This is because the rubber decoupling part has degraded.

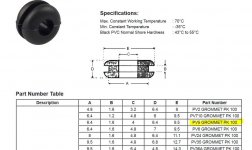

To repair this, I use two PVC grommets from Farnell, part number 152-332.

Cut off one side of each grommet, leaving the middle part intact.

With a sharp cutter knife, reduce the diameter of the crommet that goes in the arm tube, to make it fit.

That's all.

I am open to all comments.

Best regards, 968driver.

on all Thorens TP 14 tonearms I have seen, the tracking force balancing weight is sagging. This is because the rubber decoupling part has degraded.

To repair this, I use two PVC grommets from Farnell, part number 152-332.

Cut off one side of each grommet, leaving the middle part intact.

With a sharp cutter knife, reduce the diameter of the crommet that goes in the arm tube, to make it fit.

That's all.

I am open to all comments.

Best regards, 968driver.

Attachments

Gommet size

Hello.... Do you remember what the size was of the inside hole on the grommet..? Thanks.... Tom

Hello.... Do you remember what the size was of the inside hole on the grommet..? Thanks.... Tom

Thorens TP 14, decoupling grommet

Hello, I am looking for similar fix on a TP 14 that was mounted on a Thorens TD 124 I bought recently. When I searched Farnel for the part number it came up as PV5, specifications as per attachement.

I also found an original TPE 122 damping unit for sale, but the price was "on request", which already sounds expensive and probably not worth the money for this tone arm.

Hello, I am looking for similar fix on a TP 14 that was mounted on a Thorens TD 124 I bought recently. When I searched Farnel for the part number it came up as PV5, specifications as per attachement.

I also found an original TPE 122 damping unit for sale, but the price was "on request", which already sounds expensive and probably not worth the money for this tone arm.

Save

Attachments

Rubber hose used for repair

I completed the replacement of the desintegrated rubber with an alternative rubber hose. The hose is normally used for car wind screen washers, at 2,5 euro's per meter, available in any automotive shop. I got mine from Autovak in Belgium, staff were really helpful.

After I placed the hose over the square metal pin, it is still a bit square and I had to sand the corners off a little, but it ended up with a tight fit.

I then added a rubber washer, wich I had from a set I bought for an SME and reassembled (fiddly!!!).

I have not played it yet, as the TD 124 is still work in progress, but for the moment is looks pretty neat.

I completed the replacement of the desintegrated rubber with an alternative rubber hose. The hose is normally used for car wind screen washers, at 2,5 euro's per meter, available in any automotive shop. I got mine from Autovak in Belgium, staff were really helpful.

After I placed the hose over the square metal pin, it is still a bit square and I had to sand the corners off a little, but it ended up with a tight fit.

I then added a rubber washer, wich I had from a set I bought for an SME and reassembled (fiddly!!!).

I have not played it yet, as the TD 124 is still work in progress, but for the moment is looks pretty neat.

Attachments

Interesting and Careful work being displayed..

Wondering on the PVC grommets though.

PVC isn't overly compliant in my experiences.

Rubber hose seems as more appropriate material.

In that thought:

Might not a piece of Silicone tubing sliced into a suitable Ring

be a further improvement ?

Dunno.. merely speculating

Wondering on the PVC grommets though.

PVC isn't overly compliant in my experiences.

Rubber hose seems as more appropriate material.

In that thought:

Might not a piece of Silicone tubing sliced into a suitable Ring

be a further improvement ?

Dunno.. merely speculating