Hi all,

Need to seek some advise from you.

I had a TD125 MKI turntable having some issue with the rotation at 33rpm.

The good news is that the motor is turning. But the bad news is that sometimes, when you turn it ON it will rotate clockwise and turning it

OFF to ON again, it will rotate anti-clockwise. Its rotation toggle almost

everytime you power ON anf OFF again continually.

Anyone had that experience?

I notice that turning the speed to 16rpm then back to 33rpm do help to

correct the rotation problem. Also when in the ON state, changing to 16rpm,

the motor tumble and not rotating.

So far, I had changed only polarity E-Cap to new ones but no improvement.

What you guys think of this? Motor or other components on the PCB board issue?

Thank you very much.

Need to seek some advise from you.

I had a TD125 MKI turntable having some issue with the rotation at 33rpm.

The good news is that the motor is turning. But the bad news is that sometimes, when you turn it ON it will rotate clockwise and turning it

OFF to ON again, it will rotate anti-clockwise. Its rotation toggle almost

everytime you power ON anf OFF again continually.

Anyone had that experience?

I notice that turning the speed to 16rpm then back to 33rpm do help to

correct the rotation problem. Also when in the ON state, changing to 16rpm,

the motor tumble and not rotating.

So far, I had changed only polarity E-Cap to new ones but no improvement.

What you guys think of this? Motor or other components on the PCB board issue?

Thank you very much.

Hi, you need to download the service manual from vinyl engine or something

similar.Could be mechanical or electronic hence the schematic will help.

Is there really a 16rpm mode?😕Thought 33 and 45 rpm only.

similar.Could be mechanical or electronic hence the schematic will help.

Is there really a 16rpm mode?😕Thought 33 and 45 rpm only.

Hi, Went to vinyl engine and saw the TD125 AB version service manual

and user manual.According to user manual the speed control is electronic

wien bridge controlled via switching some reistors and capacitors of small

value.Power to motor is provided by a push pull amplification stage.

The speed selector switch is connected or levered to a microswitch

which is fastened by screws.It is possible the assembly may have loosened

over time or be faulty (which I doubt but who knows).I think this is the only thing you can check as the speed is all electronics unless you are a electronic person yourself.

and user manual.According to user manual the speed control is electronic

wien bridge controlled via switching some reistors and capacitors of small

value.Power to motor is provided by a push pull amplification stage.

The speed selector switch is connected or levered to a microswitch

which is fastened by screws.It is possible the assembly may have loosened

over time or be faulty (which I doubt but who knows).I think this is the only thing you can check as the speed is all electronics unless you are a electronic person yourself.

Hi, Went to vinyl engine and saw the TD125 AB version service manual

and user manual.According to user manual the speed control is electronic

wien bridge controlled via switching some reistors and capacitors of small

value.Power to motor is provided by a push pull amplification stage.

The speed selector switch is connected or levered to a microswitch

which is fastened by screws.It is possible the assembly may have loosened

over time or be faulty (which I doubt but who knows).I think this is the only thing you can check as the speed is all electronics unless you are a electronic person yourself.

Thank for your kind input and indeed I read all the info I can get from web.

However, I was seeking information from anyone here who had experienced this problem before or happen to know what is wrong.

I had been in the electronics manufacturing industry long enough (~20years) which allowed me to do some repair work on my own .

Json said

Hi, All the more you should be able to fix it.😀

I had been in the electronics manufacturing industry long enough (~20years) which allowed me to do some repair work on my own .

Hi, All the more you should be able to fix it.😀

Json said

Hi, All the more you should be able to fix it.😀

Do everyone a favour if you do not have any good input to this thread.

Thank you.

Do everyone a favour if you do not have any good input to this thread.

Thank you.

Given that Singa gave you some pretty good input on where to go to get a service manual and then more or less complemented you on your probable ability to get this sorted out your above response seems unwarranted.

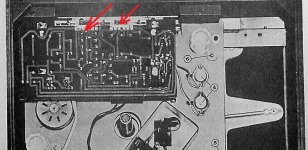

My useful input would be to go through the controller and replace all of the electrolytic capacitors in the controller. This version of the table was made from 1968 until about 1970 or so when the MKII replaced it and now the original electrolytic capacitors are very tired. I owned a MKI for about 10yrs and at a certain point it would no longer hold speed consistently and really lacked torque - all symptoms of bad capacitors. Specifically since you have the MKI it is most likely that the phase shift capacitor for 33.33 rpm is bad or the switch itself has oxidized contacts which can be fairly easily cleaned with a good contact cleaner. Does it exhibit the same problems at 16.67 or 45rpm or just this one speed?

Axial caps in all of the right values were still available from Mouser or Digikey last time I checked and presumably there are others sources more local to you. Probably the French made Vishay types are the most durable IMLE.

Take a look at Caig Labs products for a cleaner that works long term on the pcb based switches on your TD-125.

Given that Singa gave you some pretty good input on where to go to get a service manual and then more or less complemented you on your probable ability to get this sorted out your above response seems unwarranted.

My useful input would be to go through the controller and replace all of the electrolytic capacitors in the controller. This version of the table was made from 1968 until about 1970 or so when the MKII replaced it and now the original electrolytic capacitors are very tired. I owned a MKI for about 10yrs and at a certain point it would no longer hold speed consistently and really lacked torque - all symptoms of bad capacitors. Specifically since you have the MKI it is most likely that the phase shift capacitor for 33.33 rpm is bad or the switch itself has oxidized contacts which can be fairly easily cleaned with a good contact cleaner. Does it exhibit the same problems at 16.67 or 45rpm or just this one speed?

Axial caps in all of the right values were still available from Mouser or Digikey last time I checked and presumably there are others sources more local to you. Probably the French made Vishay types are the most durable IMLE.

Take a look at Caig Labs products for a cleaner that works long term on the pcb based switches on your TD-125.

Hi, thank you for the feedback.

Perhaps, it was overlook by me that I did not mentioned that I did have the service manual and did study it before asking questions.

However, below is the list of actions taken so far

1) Clean the all the contact - DONE

2) Resolder all solder point to prevent any cold joint - DONE

3) Changes all E-Cap - DONE

4) Adjusted all voltage to required 8V, 5V and 2.5V respectively for 45, 33 and 16rpm. - DONE

5) Adjust frequency to center done for 45 and 33 (except 16rpm as it was not rotating or maybe rumble)- DONE

So far, the above mentioned was done and the motor is running very consistently with spot on 33rpm. But the 45 rpm was drifting slightly most of the time. But 16rpm was the worst which cannot rotate much.

So I believed that the electronics part were working.

However, when the motor is rotating, switching the speed control will most of the time toggle the motor to rotate in counter-clockwise(especially switch from 33->16->33) instead of remaining at clockwise direction. Then you have to play around with the ON/OFF switch or speed control switch to get it back to rotate in the correct direction.

This is the problem or all the while that is what I had been searching for the answer.

My guess was the weinbridge oscillator being trigger phase in and out of phase that causing the problem.

Any ideas what caused the motor rotation change direction?

Is it a weak or dying motor?

Last edited:

Json said

hi, I did not mean to make fun or belittle anyone for that matter.

OK my 2 cents worth...from item 5 it is clear that 16 rpm does not work.

Since the input to the motor is common we can rule out the motor.

My first suspect would be the microswitch which contain 4 way double pole

switch as suggested in the service manual.Other than that as Kevinkr sugested it could be the phase shift caps.

Could be the resistors,being able to set the setup voltages does not mean

that the frequency is "set" as the value of the capacitance and resistors

determine the frequency of oscillation.Looking at the oscillator circuit the

switch selector connect parts of the oscillator as a whole so if part of the circuit is not engaged I think the oscillator will be open circuit.

I would check the capacitors out of the circuit if their values are within tolerance(small value film caps of the wein bridge oscillator).Same for the resistors and if they are ok then check the semiconductors.If drift is a problem then a scope will be useful.Note that if a motor rotates in opposite direction may indicate a change of polarity of current which may indicate leakage or reversal of polarity somewhere.

1) Clean the all the contact - DONE

2) Resolder all solder point to prevent any cold joint - DONE

3) Changes all E-Cap - DONE

4) Adjusted all voltage to required 8V, 5V and 2.5V respectively for 45, 33 and 16rpm. - DONE

5) Adjust frequency to center done for 45 and 33 (except 16rpm as it was not rotating or maybe rumble)- DONE

hi, I did not mean to make fun or belittle anyone for that matter.

OK my 2 cents worth...from item 5 it is clear that 16 rpm does not work.

Since the input to the motor is common we can rule out the motor.

My first suspect would be the microswitch which contain 4 way double pole

switch as suggested in the service manual.Other than that as Kevinkr sugested it could be the phase shift caps.

Could be the resistors,being able to set the setup voltages does not mean

that the frequency is "set" as the value of the capacitance and resistors

determine the frequency of oscillation.Looking at the oscillator circuit the

switch selector connect parts of the oscillator as a whole so if part of the circuit is not engaged I think the oscillator will be open circuit.

I would check the capacitors out of the circuit if their values are within tolerance(small value film caps of the wein bridge oscillator).Same for the resistors and if they are ok then check the semiconductors.If drift is a problem then a scope will be useful.Note that if a motor rotates in opposite direction may indicate a change of polarity of current which may indicate leakage or reversal of polarity somewhere.

Hi, thank you for the feedback.

So I believed that the electronics part were working.

This is easy to check with a scope and the service data's.

However, when the motor is rotating, switching the speed control will most of the time toggle the motor to rotate in counter-clockwise(especially switch from 33->16->33) instead of remaining at clockwise direction. Then you have to play around with the ON/OFF switch or speed control switch to get it back to rotate in the correct direction.

This is the problem or all the while that is what I had been searching for the answer.

My guess was the weinbridge oscillator being trigger phase in and out of phase that causing the problem.

Any ideas what caused the motor rotation change direction?

Is it a weak or dying motor?

YES, it is. This symptom is well know on the TD125 and the culprit is allways a defective motor. If the motor has the tendency to randomly start backwards with low couple and noisy (vibrating) operation don't search any further: replace the motor.

YES, it is. This symptom is well know on the TD125 and the culprit is allways a defective motor. If the motor has the tendency to randomly start backwards with low couple and noisy (vibrating) operation don't search any further: replace the motor.

Actually this has almost never been my experience with this turntable, almost all that exhibited this problem had electronics issues which is a good thing since these motors are not all that commonly available, although they do show up from time to time on eBay. Note that the A and B version motors are not interchangeable.

An open winding (or potentially a partially shorted winding) could also cause the symptoms described so check both windings for continuity.

Last edited:

Json , Do you cleaned and checked the switches?

Regards zeoN_Rider

Yes. I did that with Deoxy but the phenomena is the same.

Will update again when I can get more clue.

Last edited:

This circuit has germanium power transistors. These are not as reliable as silicon devices.

It looks like most of the components are unique to each speed. C4 250uF is the 16 Hz phase shifter and is a suspect.

Another suspect is the reference lamp. Is the bulb measuring between 100 and 200 ohm cold? If this goes high the voltage level will reduce

It looks like most of the components are unique to each speed. C4 250uF is the 16 Hz phase shifter and is a suspect.

Another suspect is the reference lamp. Is the bulb measuring between 100 and 200 ohm cold? If this goes high the voltage level will reduce

This circuit has germanium power transistors. These are not as reliable as silicon devices.

It looks like most of the components are unique to each speed. C4 250uF is the 16 Hz phase shifter and is a suspect.

Another suspect is the reference lamp. Is the bulb measuring between 100 and 200 ohm cold? If this goes high the voltage level will reduce

Hi, David.

Thank you for your suggestion.

The C4 had been changed to new one and I measured the bulb resistance to be ~20 ohm. I had a spare one and it gave the same value.

Actually this has almost never been my experience with this turntable, almost all that exhibited this problem had electronics issues which is a good thing since these motors are not all that commonly available, although they do show up from time to time on eBay. Note that the A and B version motors are not interchangeable.

An open winding (or potentially a partially shorted winding) could also cause the symptoms described so check both windings for continuity.

I have repaired many of these turntables and if most (but not all) problems are related to the electronic drive board I had a few motor issues too. (about 5%) When you're stuck (and it looks Json has some experience and already ruled out all the common electronic faults) you should consider a defective motor. (bad news,as replacement units are hard to find)

If you have access to a (dual trace) oscilloscope this is very easy to ascertain: monitor the two motor drive signals and check if

1) They have the correct amplitude,as described in the service manual

2) Have a quadrature (90°) phase relationship.

3) Have a perfectly sinusoidal shape (very important)

If all the 3 above criteria are met you can exclude the electronic drive (= defective motor), if not more troubleshooting in the electronic circuit is needed.

I think that if the two windings have similar dc resistance and that the shaft runs smoothly in the bearings, that the motor is OK. This is a synchronous motor, so there are no brushes to wear out. According to the manual, the bearings could need lubrication

Hi, David.

Thank you for your suggestion.

The C4 had been changed to new one and I measured the bulb resistance to be ~20 ohm. I had a spare one and it gave the same value.

I think from memory that is about right for a MKI..

Hi.

Looks like I am very late to the party...

But I have a TD125 Mk I which exhibits the same symptoms as Json. Was the problem ever resolved?

Looks like I am very late to the party...

But I have a TD125 Mk I which exhibits the same symptoms as Json. Was the problem ever resolved?

Unknown since the OP never posted again after my final comment.

I no longer own any 125s and have forgotten most of what I knew about this table so I would recommend just to read through the whole thread.

Checking to make sure the amplitude and phase relationship of the voltages fed to the motor windings are correct is an important first step.

I no longer own any 125s and have forgotten most of what I knew about this table so I would recommend just to read through the whole thread.

Checking to make sure the amplitude and phase relationship of the voltages fed to the motor windings are correct is an important first step.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- THorens TD125 MKI motor rotation problem