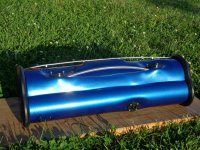

Well, now that I finished up construction on my first little experiment with small drivers and PVC I've decided to start a new thread ( after all, still a lot of measuring and tweaking to do 😉 ). If you missed the construction here's a link to the thread : http://www.diyaudio.com/forums/multi-way/253829-portable-bluetooth-speaker.html . Also, along the way it has been given a name. " The Pipe ", nice and simple.

Anyways, on to the pics...

Here's a close up of the tweeter.... I cut up a computer fan grill and used spacers and washers to make the grill.

Well, it ended up too pretty to be a " jobsite stereo " but I'm still pretty happy with it 🙂. What do you think?

Sent from my A/S7 using Tapatalk

Anyways, on to the pics...

Here's a close up of the tweeter.... I cut up a computer fan grill and used spacers and washers to make the grill.

Well, it ended up too pretty to be a " jobsite stereo " but I'm still pretty happy with it 🙂. What do you think?

Sent from my A/S7 using Tapatalk

How it sounds?

Like your twetters grill😉

Super nice design

Good question.… 🙂

Pretty good....

It does still need a little EQing ( I'll add that to the crossover ), but after that... I am very impressed! Those little Dayton 3 inch drivers will really move some air! And the Vifa tweeters, well they are Vifa tweeters, nice and natural, and do match up with the woofers pretty well.

The tweeters are 7dB louder than the woofers and I have no traditional ( l-pad, series resistance, etc... )attenuation on them. Since the tweeters are pointed straight up, the listening position is 45 or so degrees off axis, so that makes them a few dB's less. The rest of the efficiency mismatch is handled with an odd second order crossover alignment which starts the roll off real high ( which also helps with the very top end rolling off from being so far off axis ). Actual crossover point is about 2K and the tube is 6 inches in diameter, so the end result is actually omni directional... Which is pretty cool.

Oh yeah, " how does it sound?"

Surprising! This little pipe can sound quite big. Low end response is good to 45Hz or so ( just by ear so far, I haven't measured it yet.... I'm lazy 😉 ). Without EQ it's still a little bright on the top end and it could use a little bass boost but something I'll be able to take care of with the crossover. Output is incredible, gets way louder than I will ever need, which is a good thing 🙂. At reasonable levels it does have a nice laid back natural sound, with a surprisingly wide soundstage.

HOWEVER, MP3 sounds like crap!

But most people don't care, so everyone who has seen it has been amazed.... Like its some sort of " Bose magic ".... No, just brute force, LOL!

I'll post the measurements when I get the chance.

Sent from my A/S7 using Tapatalk

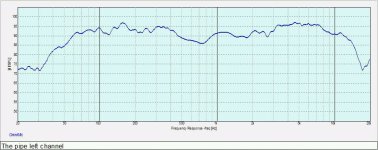

Well, I finally got around to measuring the frequency response.

Not too bad, the big dip at the top end is because of the tweeters being so far off axis. I'm still going to make another crossover which will include a 4 to 6dB drop starting at 60Hz up to 13K, which will extend the bottom end and help even out that dip at the top by sacrificing efficiency. I have plenty of power and I think ( hope ) the woofers can take it. That is, if I can get it to fit in the little space available, components could get big,lol.

Oh yeah, after over a month to let the paint cure I polished it a gave it a coat of wax. Looking good...

Not too bad, the big dip at the top end is because of the tweeters being so far off axis. I'm still going to make another crossover which will include a 4 to 6dB drop starting at 60Hz up to 13K, which will extend the bottom end and help even out that dip at the top by sacrificing efficiency. I have plenty of power and I think ( hope ) the woofers can take it. That is, if I can get it to fit in the little space available, components could get big,lol.

Oh yeah, after over a month to let the paint cure I polished it a gave it a coat of wax. Looking good...

Attachments

Last edited:

That is such a great construction project! Very professional results with the molded PVC, I could see low diffraction midrange/tweeter head assembly cabs done that way.

What is the bluetooth radio module?

David S

What is the bluetooth radio module?

David S

That is such a great construction project! Very professional results with the molded PVC, I could see low diffraction midrange/tweeter head assembly cabs done that way.

What is the bluetooth radio module?

David S

Thanks Dave.... Yeah, I'm going to have to make a dual sub/ satellite system using this method... I already have a bunch of 8" and 10" PVC and a little bit of 12" ( PVC sub cabinet/ stand too ). I even have plans to build a PVC horn enclosure using different sizes of pipe, sort of leaning into each other, to create the flare.

Oh, and the amp I used is the Lepai LL7498E. I got it from Parts Express, part number 310-298.

Oh, and speaking of Parts Express.... The Pipe is the featured project in thier July/August flyer. Full 2 page spread in the middle of the flyer! Pretty exciting stuff!

Chris

Excellent build!

I feel so inspired after reading this thread, and the one leading up to it! Really impressed how you have sculpted the pvc pipe. I had no idea this was possible!

I plan to make a speaker like the Sonos play 1, and your design and way to create an enclosure is my start point!

One question: it looks like you have a pipe laying parallel behind the one holding the speakers. Is that a separate pipe or a sculpted part off the main pipe?

Another question: do you have ports in the enclosure, it is it just details..?

I feel so inspired after reading this thread, and the one leading up to it! Really impressed how you have sculpted the pvc pipe. I had no idea this was possible!

I plan to make a speaker like the Sonos play 1, and your design and way to create an enclosure is my start point!

One question: it looks like you have a pipe laying parallel behind the one holding the speakers. Is that a separate pipe or a sculpted part off the main pipe?

Another question: do you have ports in the enclosure, it is it just details..?

@Chris.

Sorry! Was reading the first thread, and all the answers to my questions was in there. Got it now.

What program do you use for tuning the ports to the enclosure/drivers?

To glue the PVC parts together, what kind of glue do you use?

I will go and buy som PVC pipes this week, and give the first shots trying to form an enclosure myself in the coming weekend. #excited

Sorry! Was reading the first thread, and all the answers to my questions was in there. Got it now.

What program do you use for tuning the ports to the enclosure/drivers?

To glue the PVC parts together, what kind of glue do you use?

I will go and buy som PVC pipes this week, and give the first shots trying to form an enclosure myself in the coming weekend. #excited

Thanks PeterRP and Charles Darwin.

To model the enlosure tuning I used Bass Box (really and modeling software will be fine, just a simple ported box... Figuring out the enclosure volume and port surface area is the only tricky part). To verify everything I used a DATS system.

I used Gorilla Glue to glue the PVC together. All the seams are reinforced with Bondo.

The biggest tip I can give is don't force the PVC to much. It will want to crack.

Sent from my LGLS775 using Tapatalk

To model the enlosure tuning I used Bass Box (really and modeling software will be fine, just a simple ported box... Figuring out the enclosure volume and port surface area is the only tricky part). To verify everything I used a DATS system.

I used Gorilla Glue to glue the PVC together. All the seams are reinforced with Bondo.

The biggest tip I can give is don't force the PVC to much. It will want to crack.

Sent from my LGLS775 using Tapatalk

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- "The Pipe" Custom molded PVC portable Bluetooth stereo