I was putting together a BOM recently and looking at KEMET snap-fit/press-fit capacitors and was shocked (not literally) to read in the attached datasheet that this type of capacitor is not meant to be soldered in. So, I've been doing it 'wrong' for years. I'd always soldered them in, assuming the snap-fit was just to hold the capacitor secure during soldering.

The thing is, I've never seen a snap-fit capacitor just being pressed in without soldering, not in diy or commercial products. Has anyone ever seen this in a commercial product or use them the way they're intended in diy?

The thing is, I've never seen a snap-fit capacitor just being pressed in without soldering, not in diy or commercial products. Has anyone ever seen this in a commercial product or use them the way they're intended in diy?

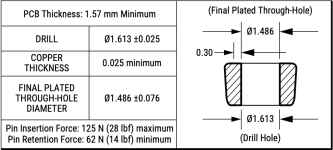

Attachments

Don't you use Wago connectors ... the fitting is similar but the other way around. The Wago connector grips the wire, the PCBoard grips the capacitor foot.

Press a wire into a tapered hole and you get an interference fit. Press it in with the correct force and we get contact interference which is similar to a cold weld and as good a contact as soldering with the added advantage of never getting a dry joint from dissimilar metals..

If the hole is the right shape, it works fine.

Ordinary Snap Fit with the commonly used curved lug, must be soldered in as the receptacle is not precise enough for interference fitting. This system only works on specific components!

Press a wire into a tapered hole and you get an interference fit. Press it in with the correct force and we get contact interference which is similar to a cold weld and as good a contact as soldering with the added advantage of never getting a dry joint from dissimilar metals..

If the hole is the right shape, it works fine.

Ordinary Snap Fit with the commonly used curved lug, must be soldered in as the receptacle is not precise enough for interference fitting. This system only works on specific components!

Attachments

I've been working in electronics for over 35 years and have never seen a snap in that was not soldered. Not saying that they aren't mounted that way and there are not data sheets specifying that - just not that I have ever encountered or seen them. For the last 15 years or so I've encountered them when restoring vintage lab grade test equipment and, for the most part it uses screw terminal mounting but there is a fair amount of snap in capacitors as well - and always soldered.