I have been asked to have a look at this turntable. The problem I have is that the platter rubs on the motor pulley as well as the upright hex shaft that I assume protects the pulley...

It is thought that this problem may have come as a result of a transport "accident".

I just can not figure this out. There is not enough space between subchassis and top plate to allow adjustment that would clear the platter from the pulley.

I am wondering if a knock may have moved the sub platter on the spindle shaft... The top of the spindle is 21 mm "high" with the mat or 28.5 mm measuring from sub platter indentation to top of spindle. Does this seem right? Could anyone verify? It seems very high...

I just can not figure why I can not get the platter to clear the pulleys....

Any help thought pointers welcomed.

Anyone got a manual for this beast?

It is thought that this problem may have come as a result of a transport "accident".

I just can not figure this out. There is not enough space between subchassis and top plate to allow adjustment that would clear the platter from the pulley.

I am wondering if a knock may have moved the sub platter on the spindle shaft... The top of the spindle is 21 mm "high" with the mat or 28.5 mm measuring from sub platter indentation to top of spindle. Does this seem right? Could anyone verify? It seems very high...

I just can not figure why I can not get the platter to clear the pulleys....

Any help thought pointers welcomed.

Anyone got a manual for this beast?

I've got a manual for the Mk II of the TD 166, which is also available at

vinylengine

The platter on my 166 (currently for sale for anyone who's reading this!) sits well above the motor pulley. There is a shaft that doesn't seem to do anything near the pulley that sits up another 2 or 3 mm.

If I adjust my suspension "up" I have more than 4 mm clearance b/w the bottom of the subplatter and the faceplate. Can you raise your suspension up to see if it will clear?

vinylengine

The platter on my 166 (currently for sale for anyone who's reading this!) sits well above the motor pulley. There is a shaft that doesn't seem to do anything near the pulley that sits up another 2 or 3 mm.

If I adjust my suspension "up" I have more than 4 mm clearance b/w the bottom of the subplatter and the faceplate. Can you raise your suspension up to see if it will clear?

Hi

I think that tubenut is right.

If you adjust the suspension, you will be OK

The shaft inwards the pulley is for to adjust the position of the motor/pulley.

There is a stiff spring below it (beneath the top plate).

By turning this shaft clockwise, the pulley goes a bit further from the platter (kind of belt tensioner).

Regards

George

I think that tubenut is right.

If you adjust the suspension, you will be OK

The shaft inwards the pulley is for to adjust the position of the motor/pulley.

There is a stiff spring below it (beneath the top plate).

By turning this shaft clockwise, the pulley goes a bit further from the platter (kind of belt tensioner).

Regards

George

I just can not figure this out. There is not enough space between subchassis and top plate to allow adjustment that would clear the platter from the pulley.

Thanks for your help so far. The problem I seem to have is that even with the subchassis touching hard up against the top plate (IOW, suspension as high as it can go), the bottom of the platter does not clear the pulley/hex shaft next to pulley.

Does anyone have a 166 they could measure the spindle height from sub platter on? Or, how many mm space should there be between the bottom of sub platter edge and the top plate?

tubenut said:

Does anyone have a 166 they could measure the spindle height from sub platter on? Or, how many mm space should there be between the bottom of sub platter edge and the top plate?

If the suspension is up against the top plate, the distance b/w the bottom of the subplatter and the subplate is 5/16" (yeah, I live in the US)

The distance b/w the bottom and the top plate would just be the thickness of the top plate then.

Could there be pieces missing inside the bearing shaft?

Could there be pieces missing inside the bearing shaft?

This is slowly becoming a strong suspicion...... The bearing spins really smooth though but a missing thrust plate or ball would just about account for the "space" I am short. Will measure this evening for "about 8 mm, I suspect I only have about 5 mm, or 3/16th for the imperialists among us.

Anyone know what should be inside the TD166 bearing housing if anything? The shaft is a dulled cone shape at the end....

Hi,

I have not seen a 166, so this is guessing from 150/160 layout.

The inside of the rim around the outer platter should sit OUTSIDE the pulley/motor spindle.

Could the inner/outer platter have moved sideways such that the inside of the rim is now fouling the outside of the motor pulley?

The platter rim is usually quite close to the stationary deck plate. This gap can be adjusted from near zero to 6mm or 7mm. It needs to be just high enough that bounce avoids the platter rim hitting the deck.

I have not seen a 166, so this is guessing from 150/160 layout.

The inside of the rim around the outer platter should sit OUTSIDE the pulley/motor spindle.

Could the inner/outer platter have moved sideways such that the inside of the rim is now fouling the outside of the motor pulley?

The platter rim is usually quite close to the stationary deck plate. This gap can be adjusted from near zero to 6mm or 7mm. It needs to be just high enough that bounce avoids the platter rim hitting the deck.

The inside of the rim around the outer platter should sit OUTSIDE the pulley/motor spindle.

It does, the hex shaft near the pulley rubs the "inside roof" of the platter....

I'm loathe to dig inside the bearing housing, but the shaft on my 166 also is a "dull cone", maybe 22' semiangle.

Anyone know more about the thrust plate on these decks?

Would it be easily visible if in place or not? IE, dull bearing shaft bottom vs shiny plate? I am sure i would need to drain the oil to check. Is it magnetic and easy to fish out with a small magent on a rod of sorts? Will it fall out if I turned the deck upside down (together with the opil if not removed 😉 )

Just trying to establish if this plate is actually there or not....

Would it be easily visible if in place or not? IE, dull bearing shaft bottom vs shiny plate? I am sure i would need to drain the oil to check. Is it magnetic and easy to fish out with a small magent on a rod of sorts? Will it fall out if I turned the deck upside down (together with the opil if not removed 😉 )

Just trying to establish if this plate is actually there or not....

Hi Tubenut,

I had a TD 166 some years ago, and while I don't remember the exact platter to spindle height, I think it was a lot less than what you mentioned in your first post. (IIRC Something like 1cm with the mat on the platter?)

I had a TD 166 some years ago, and while I don't remember the exact platter to spindle height, I think it was a lot less than what you mentioned in your first post. (IIRC Something like 1cm with the mat on the platter?)

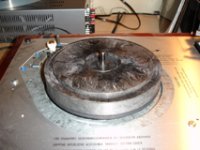

After Kevinkr post I decided to have a look and push at the subplatter/bearing....

Well, not much force moves the spindle up or down inside the cast sub platter.

So I am sure that the spindle is not in the right place. Now can anyone give me a measurement like this one from spindle top to bottom of the well in a similar subplatter. I believe there is really little difference in that part on Thorens over the years. Yes, thanks to this silly exercise and analog dept I now know more then I felt I ever needed to know about Thorens bearings, just not that vital dimension......

Any suggestions on how I keep it in place once sorted? A few drops of Locktite or crazy glue or Locknut type stuff and hope it seaps in to the crevice between shaft and sub platter hole?

Well, not much force moves the spindle up or down inside the cast sub platter.

So I am sure that the spindle is not in the right place. Now can anyone give me a measurement like this one from spindle top to bottom of the well in a similar subplatter. I believe there is really little difference in that part on Thorens over the years. Yes, thanks to this silly exercise and analog dept I now know more then I felt I ever needed to know about Thorens bearings, just not that vital dimension......

Any suggestions on how I keep it in place once sorted? A few drops of Locktite or crazy glue or Locknut type stuff and hope it seaps in to the crevice between shaft and sub platter hole?

Attachments

Hi Tubenut

Yeah I think Locktite would be the right thing, and seeing that pix I am sure that the shaft has moved quite a lot in that subplatter..

If you have the 45rpm adaptor the spindle should stick out only a couple of mm with it installed in the orientation used to play 45's - this should actually be a pretty good reference point.

Temporarily I would try the above with the mat in place and see if you can adjust the suspension over the proper range without hitting the motor pulley.

Yeah I think Locktite would be the right thing, and seeing that pix I am sure that the shaft has moved quite a lot in that subplatter..

If you have the 45rpm adaptor the spindle should stick out only a couple of mm with it installed in the orientation used to play 45's - this should actually be a pretty good reference point.

Temporarily I would try the above with the mat in place and see if you can adjust the suspension over the proper range without hitting the motor pulley.

shallbehealed said:w/o 45 adapter, from top of subplatter to tip of shaft is ~ 23/32 "

from bottom of subplatter to bottom of shaft is 2 1/32"

(see next post for photo)

But my older 166 does not have a cast subplatter, but some sort of dense polymer.

or about 18.25mm and 51.6mm respectively..

kevinkr said:

or about 18.25mm and 51.6mm respectively..

somewhere thereabouts, i was only on my 2nd cup of coffee when i measured.

while my brain might have been shaking, at least my hands weren't!

or 28.5 mm measuring from sub platter indentation to top of spindle

Seems I was on the right track from the first hunch, happens sometimes. Will not get to checking tonight but will try tomorrow PM, busy prepping for our vinyl faire tomorrow AM.

Thanks for the measurements shallbehealed and the conversions Kevinkr!

Right... So I spent this morning with this deck. Could not make it work with the dimensions given so went moved the assembly up and down a few dozen times and settlerd on 24 mm from bottom of adaptor well to tip of spindle. Tested this and re tested this. All good. I have applied some locktite type product and hope it will keep it all in place....

I did also send an e mail to Rolf Kelch, I think he was technical manager of the old Thorens company. This was his reply:

" think the turntable has the 7mm spindle and bearing. In this case the fitting between inner platter and spindle gets loose because temperature difference makes the platter material a little smooth over the years. This problem is well known and i worked out a solution. You need a 10mm spindle with a step to 7mm in the place were the inner platter is located. So the platter can not slide down. Of course You also need a 10mm bearing. We have all needed parts in stock."

I have not yet received a reply as to costs but I doubt it would be cheap. We will see how the adhesive holds up. If it fails I may well need to get the bits from Mr Kelch.

I did also send an e mail to Rolf Kelch, I think he was technical manager of the old Thorens company. This was his reply:

" think the turntable has the 7mm spindle and bearing. In this case the fitting between inner platter and spindle gets loose because temperature difference makes the platter material a little smooth over the years. This problem is well known and i worked out a solution. You need a 10mm spindle with a step to 7mm in the place were the inner platter is located. So the platter can not slide down. Of course You also need a 10mm bearing. We have all needed parts in stock."

I have not yet received a reply as to costs but I doubt it would be cheap. We will see how the adhesive holds up. If it fails I may well need to get the bits from Mr Kelch.

I love how the solution is to purchase more "bits".

I think your loctite trick should do the job, otherwise you could try any of the other million ways to cold weld. My thorens was shipped on saturday to a fellow in maryland. I hope it's happy in it's new home.

I think your loctite trick should do the job, otherwise you could try any of the other million ways to cold weld. My thorens was shipped on saturday to a fellow in maryland. I hope it's happy in it's new home.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- TD166 MKV owners/experts out there