I've been restoring my late Dad's Tandberg Series 15 tape deck, and the work on the electronics went surprisingly well (biggest issue turned out to be the preset resistors which had all failed).

I've lightly sanded the very polished rubber transfer wheel, which has made it run at the proper speed now, but the remaining issue is that the drive belt is in a poor state - polished too, but also cracking.

Problem is I can't seem to find a UK source for the belt - and in fact I can find only one source anywhere - in the US, which means that shipping would cost more than the belt.

Does anyone know of a UK source, either for the correct belt, or for a generic belt that will fit? I'm led to believe that maybe an OB21.1 or OB21.9 round belt might fit - but both seem too short compared with the existing one (though I guess it could have stretched 50mm?). The existing belt measures approx 2.6mm * 600mm and is round in section.

[Edit - actually, the OBxx.x references are probably a dead end - I think they may be obsolete stock codes for a US manufacturer, and they are only available from one source, again in the US].

I've lightly sanded the very polished rubber transfer wheel, which has made it run at the proper speed now, but the remaining issue is that the drive belt is in a poor state - polished too, but also cracking.

Problem is I can't seem to find a UK source for the belt - and in fact I can find only one source anywhere - in the US, which means that shipping would cost more than the belt.

Does anyone know of a UK source, either for the correct belt, or for a generic belt that will fit? I'm led to believe that maybe an OB21.1 or OB21.9 round belt might fit - but both seem too short compared with the existing one (though I guess it could have stretched 50mm?). The existing belt measures approx 2.6mm * 600mm and is round in section.

[Edit - actually, the OBxx.x references are probably a dead end - I think they may be obsolete stock codes for a US manufacturer, and they are only available from one source, again in the US].

Last edited:

Seems not to be a common issue - but then I don't imagine the consumer-level (as opposed to professional) Tandberg products sold in very big numbers.

Perhaps a different approach - did Tandberg copy any other reel-to-reel manufacturers in their figure-of-eight turntable drive belt design? Perhaps there are other contemporary products that Tandberg used common components with?

As far as I can tell, the belt is round, 2.6-2.8 mm diameter section* and approximately 600mm in circumference (i.e. approx 190mm diameter), but both are probably stretched to an unknown degree..

* the slight vagueness here is that I have two old belts for it and one is a slightly larger section.

Perhaps a different approach - did Tandberg copy any other reel-to-reel manufacturers in their figure-of-eight turntable drive belt design? Perhaps there are other contemporary products that Tandberg used common components with?

As far as I can tell, the belt is round, 2.6-2.8 mm diameter section* and approximately 600mm in circumference (i.e. approx 190mm diameter), but both are probably stretched to an unknown degree..

* the slight vagueness here is that I have two old belts for it and one is a slightly larger section.

Have you thought about Polyurethane Belt?

Readily available including from RS. Weld to the length you need.

Readily available including from RS. Weld to the length you need.

I had considered, but the problem is that they only seem to be sold in mm increments, and I don't think either 2mm or 3mm will work!

Seems that there are two main types of belts pre and post series 5.

www.lydshop.no seem to have both types as well as the belt for the counter in stock at approximately GBP 15.

www.lydshop.no/shop/product/drivremm-tandberg

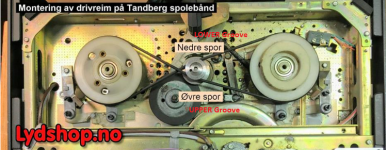

The image attached is from their website and details belt installation.

Home | Soundsmith also seem to be able to supply at about same price.

www.lydshop.no seem to have both types as well as the belt for the counter in stock at approximately GBP 15.

www.lydshop.no/shop/product/drivremm-tandberg

The image attached is from their website and details belt installation.

Home | Soundsmith also seem to be able to supply at about same price.

Attachments

Last edited:

Thanks LJT - that's very useful, as is the picture - because it confirms that the way the old belt is fitted now is how it's meant to be! Surprisingly the Service Manual does not include a diagram showing how the main drive belt should be installed.

I couldn't find any link via the index on Soundsmith's website to drive belts, but I guess that Lydshop is the way to go anyway.

Thanks for your help.

I couldn't find any link via the index on Soundsmith's website to drive belts, but I guess that Lydshop is the way to go anyway.

Thanks for your help.

What have they thought at Tandberg's when they decided to cross the left drum's drive belt 😱 ? Is this planned obsolescence?

Best regards!

Best regards!

I've seen that discussed elsewhere, and it seems to be a practical measure so that they did not need two drive belts instead of the one, plus I think it saves one additional component.

If the belt did not cross then one tape reel would go in the wrong direction!

In practice it shouldn't cause any extra wear, as the belt cannot touch where it crosses - there are two separate grooves in the drive wheel.

If the belt did not cross then one tape reel would go in the wrong direction!

In practice it shouldn't cause any extra wear, as the belt cannot touch where it crosses - there are two separate grooves in the drive wheel.

Ah, now I see it's only one belt instead of two that I've been thinking of. I'm wondering, though, about the rather small contact areas between the pulley and the belt 😕.

Best regards!

Best regards!

> rather small contact areas

The Tandberg is no Crown. Spooling is gentle. 7" reels are not hard to turn. Total time at high speed is usually not large (unless it is a dedicated rewinder in library or studio); play slippage is gentle. Anyway this belt is super-simple and cheap to replace as needed, and the wonky path saves much expense. Simply visit your local Tandberg dealer, before he goes out of business (mid-1980s?).

Since this is a reel drive, not a capstan drive, exact belt specs should be un-fussy. An mm either way is probably fine. As said, there is belting sold in bulk which can be cut to fit and heat-spliced.

The Tandberg is no Crown. Spooling is gentle. 7" reels are not hard to turn. Total time at high speed is usually not large (unless it is a dedicated rewinder in library or studio); play slippage is gentle. Anyway this belt is super-simple and cheap to replace as needed, and the wonky path saves much expense. Simply visit your local Tandberg dealer, before he goes out of business (mid-1980s?).

Since this is a reel drive, not a capstan drive, exact belt specs should be un-fussy. An mm either way is probably fine. As said, there is belting sold in bulk which can be cut to fit and heat-spliced.

A good source (at least over here) is O-ring or rubber gasket shops. You just have to tell the diameter and thickness. The diameter (of the circle) can be calculated by measuring the length. The length can be measured by spanning a thread over the pulleys.

Last edited:

I'm wondering, though, about the rather small contact areas between the pulley and the belt

I was thinking the same thing, but judging by the way the rest of it is built (cast, chromed alloy control knobs, for example) I reckon they knew what they were doing. I think the small contact area is so that it can handle the over-run when someone bashes the control stick from "FF" to "Stop". It deliberately allows for slip rather than having the belt stretch or snap.

Since this is a reel drive, not a capstan drive, exact belt specs should be un-fussy. An mm either way is probably fine. As said, there is belting sold in bulk which can be cut to fit and heat-spliced.

Perhaps I should re-measure. I'm fairly sure that 2mm won't be strong or durable enough. 3mm might work, but only if it will sit properly in the drive pulleys. Offhand I don't think it will, but I should check.

I just bought a replacement belt for a series 12 off eBay.

I’ll let you know what it’s like when it arrives.

I’ll let you know what it’s like when it arrives.

A good source (at least over here) is O-ring or rubber gasket shops. You just have to tell the diameter and thickness. The diameter (of the circle) can be calculated by measuring the length. The length can be measured by spanning a thread over the pulleys.

Thanks - I had looked at this, but the belt is 600mm circumference! I could only find readily available O-rings up to 500mm. No doubt bigger are available, but I doubt they would be thin enough.

Nitrile O Ring | Metric | 150mm - 199.99mm | Bearing Station

3mm thick available.

If that's too thick, go with the 2mm poly belting.

3mm thick available.

If that's too thick, go with the 2mm poly belting.

...Nitrile O Ring | Metric | 150mm - 199.99mm....

He wants 600mm.

The largest on that site is 530mm. Hardly bigger than the 500mm he already found.

That site also has bulk "cord", but only to 1 Meter; he needs 1.885 meters. (Could call and see if they cut to order.)

Sorry for the confusion - I should have said that it's 600mm circumference, not diameter, so one of the sizes would probably be Ok.

But I'm not convinced about using O-rings as drive belts. They are primarily designed for sealing under compression, rather than maintaining tension, and I think the "spare" belt that I have - which is stretched far more than the original from the early seventies despite being much newer - is probably nitrile.

But I'm not convinced about using O-rings as drive belts. They are primarily designed for sealing under compression, rather than maintaining tension, and I think the "spare" belt that I have - which is stretched far more than the original from the early seventies despite being much newer - is probably nitrile.

I think you are over-thinking it.

1mtr of 2mm poly belt is £3.

By making your own belt you can fine-tune the tension.

The poly-belt is designed for driving and will likely outlast a rubber belt and probably the machine.

Get 2 mtrs and you can have 3 goes at making a belt!

1mtr of 2mm poly belt is £3.

By making your own belt you can fine-tune the tension.

The poly-belt is designed for driving and will likely outlast a rubber belt and probably the machine.

Get 2 mtrs and you can have 3 goes at making a belt!

I think you are over-thinking it.

I'm thinking about it, rather than over-thinking it. Once I've put this thing back together, I don't want to have to keep taking it apart to mess about with the belt!

The issue with a belt that is half a mm too thin is that the correct size belt is designed to contact the whole of the surface of the half-round pulleys. A 2mm belt will just sit at the bottom of the groove and so will have much less contact area. Whether you can compensate for this by just adding more tension - without longer term consequences - I don't know.

The other issue with a non-rubber belt is that it may not handle slip well. You can see this on the non-rubber belt, where grooves and flat spots have been worn into it - presumably by sudden braking when going from fast forward/rewind to stop. The non-rubber belt is polished to a shiny finish, while the original rubber one is not - which is presumably why it was taken out and the original (stretched) one put back.

- Home

- Source & Line

- Analogue Source

- Tandberg Series 15 reel-to-reel drive belt