You could make a frame. It would be very hard to fix that perfectly.

Edit: Sandwich it between two pieces of 3/4" plywood and park you car on it overnight.

Edit: Sandwich it between two pieces of 3/4" plywood and park you car on it overnight.

Ask someone who works in a machine shop or sheetmetal shop, as they will have the press to bend it back and the flat surface to check it against.

(Just holding it flat won't work: It needs to be taken past the yield point.)

(Just holding it flat won't work: It needs to be taken past the yield point.)

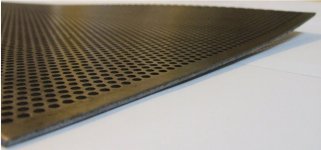

You may find that when you assemble it into a sandwich under pressure, the resulting cell is flat. My stators have a noticeable bow unassembled, which straightened out beautifully when I glued the whole shmeer together.

Tosh said:Just holding it flat won't work: It needs to be taken past the yield point.

Great to hear that close enough may be OK. The other three have a slight and simple warp which I suspected would work well enough.SY said:You may find that when you assemble it into a sandwich under pressure, the resulting cell is flat. My stators have a noticeable bow unassembled, which straightened out beautifully when I glued the whole shmeer together.

I was thinking of parking my car on it like ak_47_boy suggested. I somehow knew what Tosh says is true, and I hope that by leaving it for a while the thermal cycling may give it what it needs.

I guess since I was planning to use 1/16" spacing and foam double sided tape, and due to my inexperience I was afraid it wouldn't be good enough.

- Status

- Not open for further replies.