I have been living with a pair of Woden Design Vulcan's driven by a 6w Decware Rachael tube amp and am very happy with them in the home environment, but am looking for another project build to use in my big cabinet shop to be driven by a 100w or so solid state amp (I have an old Hafler laying around unused).

Any suggestions for a design and speaker to be used in a much larger space where volume will be more of an issue?

Thanks

Any suggestions for a design and speaker to be used in a much larger space where volume will be more of an issue?

Thanks

Em-Ken?

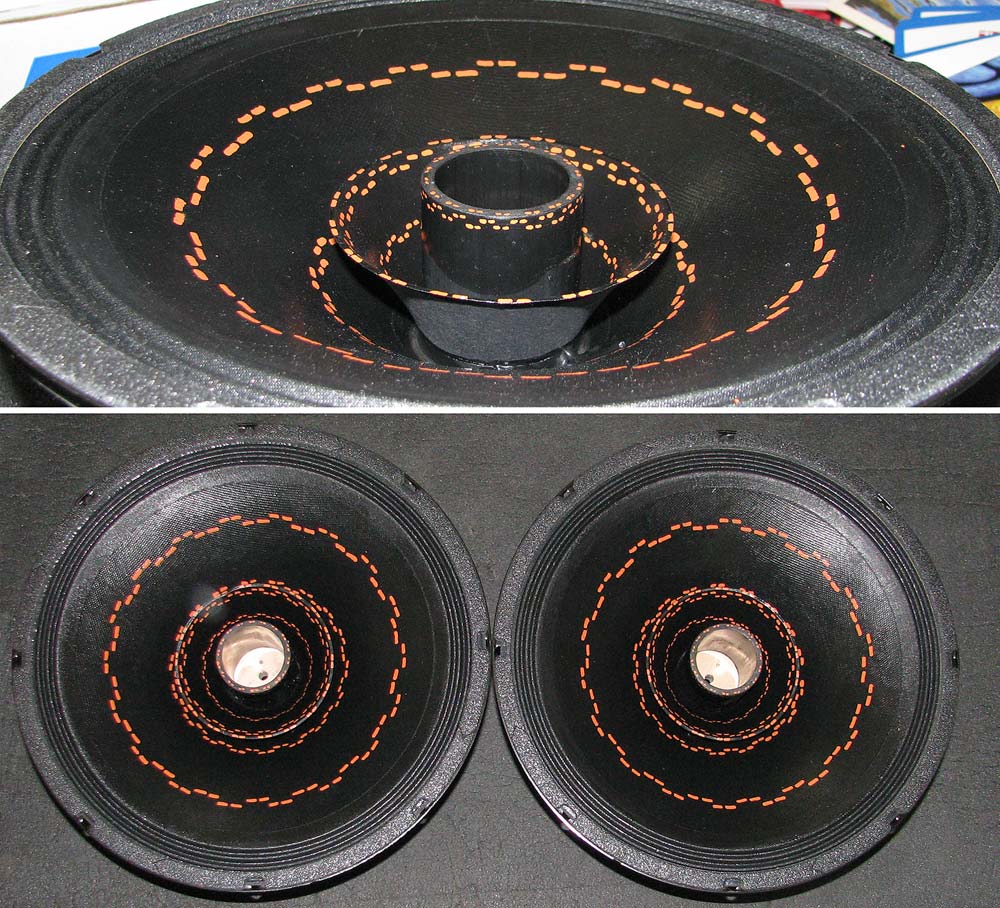

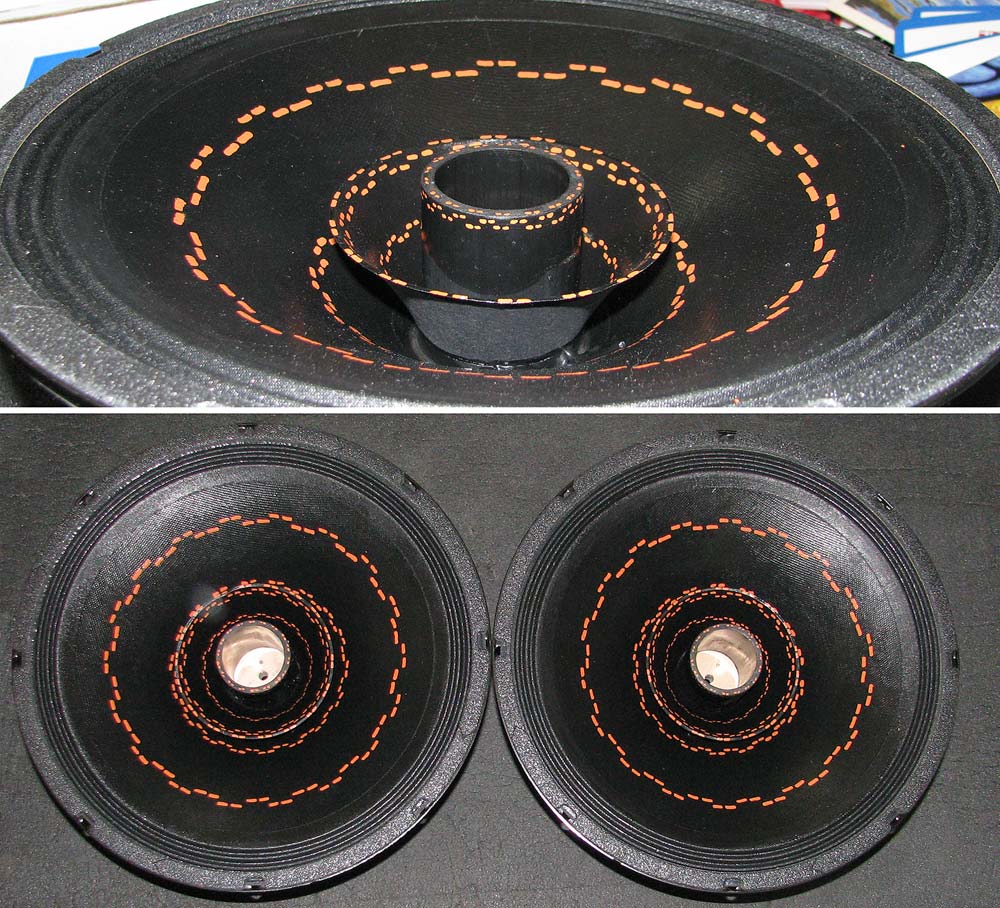

We have been working on these for sometime, ostensibly for use in PA work (slowly). Our goal is for a speaker that will fill this role and still be usable as a PA speaker. This summer we did get to the point where we were happy with the sound in a hifi role. Took quite a bit of work on the driver (Eminence 12LTA). Some here are quite happy with the driver in stock form (less dust caps).

They are about the same efficiency as Vulcan, but handle more power, and being a 12" move more air. They do need a tweeter -- the one you see is a cap coupled Foster, the one used in the radio shack pods.

We have also done a test fit of a Fostex FT17 mounted in some plumbing fittings that can be fitted as a Phase plug… given the high XO that arrangement would be good, we will proceed with that next.

All the drivers are quite inexpensive.

dave

We have been working on these for sometime, ostensibly for use in PA work (slowly). Our goal is for a speaker that will fill this role and still be usable as a PA speaker. This summer we did get to the point where we were happy with the sound in a hifi role. Took quite a bit of work on the driver (Eminence 12LTA). Some here are quite happy with the driver in stock form (less dust caps).

They are about the same efficiency as Vulcan, but handle more power, and being a 12" move more air. They do need a tweeter -- the one you see is a cap coupled Foster, the one used in the radio shack pods.

We have also done a test fit of a Fostex FT17 mounted in some plumbing fittings that can be fitted as a Phase plug… given the high XO that arrangement would be good, we will proceed with that next.

All the drivers are quite inexpensive.

dave

That looks perfect!

"Took quite a bit of work on the driver (Eminence 12LTA)." Would you do your treatment to a pair for sale?

"Took quite a bit of work on the driver (Eminence 12LTA)." Would you do your treatment to a pair for sale?

Hi, search on "Econowave" is an idea, rgds, sreten.

Thanks, will check it out...

Depending on the noise in your workshop, you might not need to add a tweeter to the EmKen.

My EmKens 12lta's dont have the 'P10 pox' but do have an awfu'lotta basket damping going on.

My EmKens 12lta's dont have the 'P10 pox' but do have an awfu'lotta basket damping going on.

I'd definitely concur that the 12LTA need some type of tweeter, and something like the FT17H makes sense. We use the old Radio Shack version because they were at hand, and with the plastic mounting case, handy to use.

So I am building these right now with the Eminence 12LTA that I found neglected in a closet (Dave modded).

I am looking at the Fostex FT17H for a tweeter. I'll set in on top of the enclosure with a stand of some sort.

What do I need in terms of a crossover?

Thanks

I am looking at the Fostex FT17H for a tweeter. I'll set in on top of the enclosure with a stand of some sort.

What do I need in terms of a crossover?

Thanks

Essentially you'll have to perform measurements to see where you want to cross it over, how steep, and with what alignment. I think I set mine around 1kHz Linkwitz-Riley second order but it's been a while now. There are so many objectives to satisfy with a crossover design that there's no "one-size-fits-all" answer.

I never did get phase plugs with these- just a hollow cylinder, unfinished on the inside, that pops in and is held by a magnet- can post pic tomorrow.

Only 2 pair of the wood plugs were ever made. The plumbing pipe (ie Deckard-style) prototype phase plugs fit (i got help from chris with the wooden base). These are essentially part of the plumbing pipe fixture i mocked up to mount an FT17 coaxially (bolted in place thru the pole-piece vent).

dave

dave

Yes, The ARC stuff is of particular interest… one of my 1st projects was a PCB for the SP3A (which in the end was a mirror image of intended — but Jesse made it work (ugly as hell thou).

dave

dave

They are assembled with the Fostex FT17H's.

The low end is lacking and mids a bit but I am in a big 2400sf open building and I haven't pushed the volume yet.

Where do I start in terms of acoustic damping? Acousta-stuff or sheet material and where?

I did build with removable back and the front/back internal brace as well as both side braces.

The low end is lacking and mids a bit but I am in a big 2400sf open building and I haven't pushed the volume yet.

Where do I start in terms of acoustic damping? Acousta-stuff or sheet material and where?

I did build with removable back and the front/back internal brace as well as both side braces.

Damping of the Em-Ken consists of nominal 12mm cotton or wool felt (or the subs that should be in the notes) on all the walls. Low density damping (like polyfill biting) can be placed on the centre side of any holey braces.

How long did you make the vent shelves?

dave

How long did you make the vent shelves?

dave

- Status

- Not open for further replies.

- Home

- More Vendors...

- Planet 10 hifi

- Speaker to move some air in work shop?