Are there any good alternate sources for less expensive crossover parts? I've checked Madisound, Miniscus, Parts Express, and even Erse direct (no reply yet from them). Is there any I'm missing? My current list is around $200 and I'd like to cut that down, if possible.

2 10 ohm 10 watt

2 3.3 ohm 10 watt

4 4 ohm 10 watt

4 15 ohm 10 watt

2 8.2 5W

2 3.3 5W

2 3 uf

2 40 uf

2 8.2 uf

4 12 uf

2 16 uf

2 2.0 mH

4 1.5 mH

2 .33 mH

2 10 ohm 10 watt

2 3.3 ohm 10 watt

4 4 ohm 10 watt

4 15 ohm 10 watt

2 8.2 5W

2 3.3 5W

2 3 uf

2 40 uf

2 8.2 uf

4 12 uf

2 16 uf

2 2.0 mH

4 1.5 mH

2 .33 mH

That's most of the usual suspects, but maybe someone at diyAudio has enough spare parts

so they can make you up a cheaper parts kit.

so they can make you up a cheaper parts kit.

I can check what the prices are on LCSC? I'm ordering soon, and perhaps things will overlap for us. Some of these values may also be possible by adding other components on to each other.

If you have a good RCL meter you can wind your own coils cheap. Just buy 18 gauge magnet wire from Amazon, a half pound roll will do for all the coils. Go 16 gauge if you want. Wind them around a dowel and zip tie them to hold them together, put the zip tie on the dowel before you wind them so you can zip them before you slide it off.

Winding my own is an interesting idea. I just have one of the super cheap meters with the clip on leads, 4 buttons and open circuit board. On the ones I tested it on it read accurately though.

Or cut some notches in the dowel... Then you can zip even after you wind.

You might be able to get the resistors through a NOS surplus, and shave a bit off, but that is finding one locally. All Electronics, Apex Jr, Mouser, Digikey, etc.

Depending, Solen or Parts Connexion are also options in Canada.

Honestly, the coils are the hardest to source.

Wolf

You might be able to get the resistors through a NOS surplus, and shave a bit off, but that is finding one locally. All Electronics, Apex Jr, Mouser, Digikey, etc.

Depending, Solen or Parts Connexion are also options in Canada.

Honestly, the coils are the hardest to source.

Wolf

If you plan to wind, this is easier:

Anyone custom wind inductors?

I like using PVC pipe sections for the bobbin.

I recommend TemCo wire, and order in 10# spools. With this amount of copper, the best gauges are 18-14. 12AWG gets harder on the hands as it requires more strength, and you don't get much length on a 10# spool in that gauge.

Later,

Wolf

Anyone custom wind inductors?

I like using PVC pipe sections for the bobbin.

I recommend TemCo wire, and order in 10# spools. With this amount of copper, the best gauges are 18-14. 12AWG gets harder on the hands as it requires more strength, and you don't get much length on a 10# spool in that gauge.

Later,

Wolf

Wolf, nice setup. Those wheels are slick. It always impresses me the skill that some people have in making the tools to make things.

It looks like something fun to try.

It looks like something fun to try.

If you plan to wind..

I recommend TemCo wire, and order in 10# spools. With this amount of copper, the best gauges are 18-14..

With this in the context of resistance (resistors in circuit), when possible try to obtain your resistance value from the Inductor itself rather than using a resistor: not only does it cost less to do so but the subjective result is typically better (and in some positions like a series connection with the driver - MUCH better).

This means that wire gauge for the Inductor is something you need to plan for to obtain the desired resistance.

Last edited:

For about $225 I built myself a universal crossover development kit. This has air coil inductors from 0.1mH (2), 0.2mH (2), 0.33mH (2), 0.5mH (2), 0.68mH, 1.0mH, 2.0mH

Iron core 1.0mH, 2.0mH, 3.0mH, 4.0mH, 10mH.

MKP film caps 0.47uF (2), 1.0uF (2), 2.2uF (4), 3.3uF (4), 4.7uF (4), 6.8uF(2), 10uF(2), 15uF (2), 30uF (2); bipolar 50uF (4), bipolar 100uF (4);

Resistors all 10w 2% Audio Grade cement filled: 0.1R (2), 0.22R(4), 0.33R(4), 0.47R(10), 0.7R(4), 1R(4), 2.2R(4), 3.3R(4), 4.7R(8), 6.8R(4), 10R(4), 12R(4), 20R(4), 30R(4).

These were all from Parts Express.

It’s wonderful having this kit and a bag of Wago connectors. I can prototype 98% of any crossover design that I can come up with and test quickly in 15min. If it works, I’ll order the correct value that I had to build up with for the final speaker.

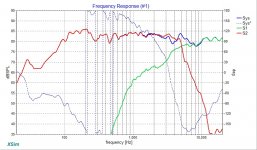

For example, XO for my Rockville homage to LS3/5A:

Or here:

The best $225 I ever spent on audio. I use it All the time. About 8 speakers now and counting. I can measure, design, test all in one evening.

Iron core 1.0mH, 2.0mH, 3.0mH, 4.0mH, 10mH.

MKP film caps 0.47uF (2), 1.0uF (2), 2.2uF (4), 3.3uF (4), 4.7uF (4), 6.8uF(2), 10uF(2), 15uF (2), 30uF (2); bipolar 50uF (4), bipolar 100uF (4);

Resistors all 10w 2% Audio Grade cement filled: 0.1R (2), 0.22R(4), 0.33R(4), 0.47R(10), 0.7R(4), 1R(4), 2.2R(4), 3.3R(4), 4.7R(8), 6.8R(4), 10R(4), 12R(4), 20R(4), 30R(4).

These were all from Parts Express.

It’s wonderful having this kit and a bag of Wago connectors. I can prototype 98% of any crossover design that I can come up with and test quickly in 15min. If it works, I’ll order the correct value that I had to build up with for the final speaker.

For example, XO for my Rockville homage to LS3/5A:

Or here:

The best $225 I ever spent on audio. I use it All the time. About 8 speakers now and counting. I can measure, design, test all in one evening.

Attachments

Last edited:

With this in the context of resistance (resistors in circuit), when possible try to obtain your resistance value from the Inductor itself rather than using a resistor.

My intent was for use in making coils related to the length of wire off of a spool, as well as ease of winding. Of course, I measure the coils for the DCR after the fact, and generally use large enough gauge when doing as suggested.

Wolf

I'll have to double check my selections. I may have gone with expensive caps and resistors because my short list is coming up close to your toolkit list. The larger inductors on the plans are listed as 18 gauge air core so that adds up a bit. Although I have 2.7s that I plan to unwind to 2.0 but it does use 4 of the 1.5mH ones.

On Amazon I mostly find parts express ones, but I'll dig some more. I emailed erseaudio but haven't gotten a reply so they are off the table for now.

On Amazon I mostly find parts express ones, but I'll dig some more. I emailed erseaudio but haven't gotten a reply so they are off the table for now.

It would be far more helpful to actually see the circuit:

..for deciding which components should be of better quality, and which components aren't.

(..the 2 different value cap.s I linked to are high value for subjective performance, but even they might be substituted for less expensive parts depending on their position.)

..for deciding which components should be of better quality, and which components aren't.

(..the 2 different value cap.s I linked to are high value for subjective performance, but even they might be substituted for less expensive parts depending on their position.)

Last edited:

My intent was for use in making coils related to the length of wire off of a spool, as well as ease of winding. Of course, I measure the coils for the DCR after the fact, and generally use large enough gauge when doing as suggested.

Wolf

I was just "adding-to" in favor of ditching resistors (where possible).

I really HATE resistors. 😀 (..especially the "cement" variety like the ones shown in XRK's post above.) 😱

Last edited:

It would be far more helpful to actually see the circuit:

..for deciding which components should be of better quality, and which components aren't.

(..the 2 different value cap.s I linked to are high value for subjective performance, but even they might be substituted for less expensive parts depending on their position.)

That makes a lot of sense. It isn't an openly published circuit so I didn't want to add it here.

The 3uF and a 12uF are in series with the tweeter (the 3 is paralleled with a resistor)

The 40uF is in series with the woofer (paralleled with an inductor and resistor).

The 8.2uf, a 12uf and 16uf all go from the woofer signal to ground.

From my little bit of knowledge, I'd guess the 3 and 12 on the tweeter are the most critical. (recommendations for a good 3uF? and the other woofer ones?)

The prices on the ones you linked are reasonable enough, especially with the quality being high. I'd rather not skimp now and then wonder later if I should 'upgrade'.

For a test XO, the cement filled Dayton’s for $1.50 ea are economical. They actually don’t sound bad. I have used the more expensive name Mills green ones $6 - not sure I can measure or hear the difference. One place they do make a difference is as a dummy load for amp testing. No wire wound is good. Only bulk metal or metal thin film works for low distortion dummy loads. Even pricey MOX ones have high distortion.

Also, to save money for a XO dev kit - use smaller gauge and iron core inductors where possible. Swap out with air core later if it sounds good and you feel it’s in the critical path, change to air core or even flat copper foil air core inductors. Of course DCR changes need to be accommodated. For woofer duties, I have straight flat plate iron cores to sound very good and they keep DCR low for more bass.

Also, to save money for a XO dev kit - use smaller gauge and iron core inductors where possible. Swap out with air core later if it sounds good and you feel it’s in the critical path, change to air core or even flat copper foil air core inductors. Of course DCR changes need to be accommodated. For woofer duties, I have straight flat plate iron cores to sound very good and they keep DCR low for more bass.

Last edited:

stupid question. Do the layers have to be individual and neat or can it be messy, as long as they are tight?

With 18 gauge wire, it sometimes wants to go where it wants to go.

With 18 gauge wire, it sometimes wants to go where it wants to go.

- Home

- Loudspeakers

- Multi-Way

- sources for crossover parts