In the mid - nineties, Sony hyped the "Fixed Pickup Mechanism".

It was first introduced with the professional CDP-5000 from 1982

Sony CDP-5000 on thevintageknob.org

Then they resurrected it in the mid nineties, claiming sonic benefits: The laser stays put, but the disc moves.

I guess they simply did this back in 1982 - just before the official introduction of the CD- because they did not know how to move the laser 🙂

But in the mid-nineties many people were happy to play around with heavy brass pucks to get back the "analogue record" - like feel.

Including me.

It was used in many players:

X5000, X3000, XA-50ES, XA-20ES, XA-7ES, CDP-R10, SCD-1, SCD-777ES and some more.

Here is my CDP-X5000

Sony CDP-X5000 on thevintageknob.org

But I was not much into electronics back then.

Hence I did not know that heavy materials / pucks might be great for vinyl, but they are nonsense for CDs.

This was just marketed by Sony to attract audiophiles to digital gear.

Also the mechanism might wear out. Some pictures can be found here:

Sony CDP-X5000 / CDP-XA7ES / CDP-XA50ES Mechanics Maintenance / VFD Modification - diyAudio

Yesterday I replaced the brass puck with a very old plastic puck from a 1984 Second generation Toshiba XR-Z70.

The puck is basically two plasic shells with a magnet inside, part of the clamping mechanisme hidden inside the player.

It took me some time to drill a centered precise hole 6mm in diameter which has no play.

Using a 6mm drill would give too much play, I used a 5.8mm and polished the hole until it reached 6mm.

But it worked!

The weight of the modified must be about one fifth of the original brass puck The pressure is now obtained by the magnet and not by weight -

like in 99% of all CD/DVD/Blu-Ray players and computer drives out there.

My X5000 works flawlessy. Pressing the the "Stop" button makes the CD stop in a fraction of a second.

But I will also have a lighter puck milled from aluminium and POM, using magnets as well.

Maybe DIYers want to step in?

I will post a first draft of the design tomorrow, along with a photos of the

mod with the Toshiba plastic puck.

All the best,

Salar

It was first introduced with the professional CDP-5000 from 1982

Sony CDP-5000 on thevintageknob.org

Then they resurrected it in the mid nineties, claiming sonic benefits: The laser stays put, but the disc moves.

I guess they simply did this back in 1982 - just before the official introduction of the CD- because they did not know how to move the laser 🙂

But in the mid-nineties many people were happy to play around with heavy brass pucks to get back the "analogue record" - like feel.

Including me.

It was used in many players:

X5000, X3000, XA-50ES, XA-20ES, XA-7ES, CDP-R10, SCD-1, SCD-777ES and some more.

Here is my CDP-X5000

Sony CDP-X5000 on thevintageknob.org

But I was not much into electronics back then.

Hence I did not know that heavy materials / pucks might be great for vinyl, but they are nonsense for CDs.

This was just marketed by Sony to attract audiophiles to digital gear.

Also the mechanism might wear out. Some pictures can be found here:

Sony CDP-X5000 / CDP-XA7ES / CDP-XA50ES Mechanics Maintenance / VFD Modification - diyAudio

Yesterday I replaced the brass puck with a very old plastic puck from a 1984 Second generation Toshiba XR-Z70.

The puck is basically two plasic shells with a magnet inside, part of the clamping mechanisme hidden inside the player.

It took me some time to drill a centered precise hole 6mm in diameter which has no play.

Using a 6mm drill would give too much play, I used a 5.8mm and polished the hole until it reached 6mm.

But it worked!

The weight of the modified must be about one fifth of the original brass puck The pressure is now obtained by the magnet and not by weight -

like in 99% of all CD/DVD/Blu-Ray players and computer drives out there.

My X5000 works flawlessy. Pressing the the "Stop" button makes the CD stop in a fraction of a second.

But I will also have a lighter puck milled from aluminium and POM, using magnets as well.

Maybe DIYers want to step in?

I will post a first draft of the design tomorrow, along with a photos of the

mod with the Toshiba plastic puck.

All the best,

Salar

Last edited:

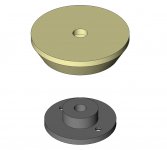

Here are the photos of the mod:

The original brass pulley and the preliminary replacement in action.

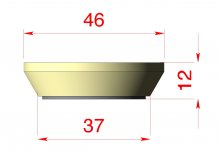

The drawings are the final replacement, made of sandblasted anodized aluminium, (yellow) holding two Neodyme magnets (not shown) and a Polyoxymethylene base (black).

It weights a third of the original brass pulley! Still the Neodyme magnets provide enough clamping force.

Having a larger quantity milled and anodized would not be very expensive; most of the cost goes into preparing the CNC machines.

So everyone using a fixed pickup player is invited to step in!

The original brass pulley and the preliminary replacement in action.

The drawings are the final replacement, made of sandblasted anodized aluminium, (yellow) holding two Neodyme magnets (not shown) and a Polyoxymethylene base (black).

It weights a third of the original brass pulley! Still the Neodyme magnets provide enough clamping force.

Having a larger quantity milled and anodized would not be very expensive; most of the cost goes into preparing the CNC machines.

So everyone using a fixed pickup player is invited to step in!

Attachments

Hello Salar,

some years ago I purchased this one ( http://www.clearlight-audio.com/content/page.php?id=43 ) for ~100€ - well worth it, more open, detailed and smooth sound, and very small weight also...have fun, Philipp

some years ago I purchased this one ( http://www.clearlight-audio.com/content/page.php?id=43 ) for ~100€ - well worth it, more open, detailed and smooth sound, and very small weight also...have fun, Philipp

Would it be possible to DIY something similar? For me 100 € is unsane

What should be the design criteria and operation mechanism for such puck?

- Light weight/heavy weight for less/more inertia?

- Vibration damping?

- Better pushing the CD to the tray?

- Magnetic push or weight push?

- Some optical effect that the current state of science is not able to explain?

- Peace of mind? (I spent 2x the price of a CD player, I HAVE TO hear something...)

I also used a brass puck, but to be honest I am not sure if it caused any improvement.

What should be the design criteria and operation mechanism for such puck?

- Light weight/heavy weight for less/more inertia?

- Vibration damping?

- Better pushing the CD to the tray?

- Magnetic push or weight push?

- Some optical effect that the current state of science is not able to explain?

- Peace of mind? (I spent 2x the price of a CD player, I HAVE TO hear something...)

I also used a brass puck, but to be honest I am not sure if it caused any improvement.

Salar whether or not you agree with a fellow member's comment, keep your response respectful. Post deleted. Please read the forum rules.

Salar whether or not you agree with a fellow member's comment, keep your response respectful. Post deleted. Please read the forum rules.I am sorry but my answer was not unrespectful against invisible force but

the kind of snake oil Clearaudio sells.

If they wrote:

"This puck puts lesser stress on the motor and bearings ad expand their longetivety",

o.k., this would be certainly the effect, (If the puck is well centered and balanced)

But lines like:

"The XA 50 ES now offers a much more deeper and more structured sound.

Even better "space" and more "voices" are among the improvements that caused by the RDC puck."

This cannot be taken seriously...

About large pucks:

In general, I think vibrations caused by 500-200 rpm are a myth.

A 40x speed CD-Rom, this vibrates!

With large pucks like the one from Clearaudio i would be also worried about angular errors.

The center hole must be absolutely rectangular.

the kind of snake oil Clearaudio sells.

If they wrote:

"This puck puts lesser stress on the motor and bearings ad expand their longetivety",

o.k., this would be certainly the effect, (If the puck is well centered and balanced)

But lines like:

"The XA 50 ES now offers a much more deeper and more structured sound.

Even better "space" and more "voices" are among the improvements that caused by the RDC puck."

This cannot be taken seriously...

About large pucks:

In general, I think vibrations caused by 500-200 rpm are a myth.

A 40x speed CD-Rom, this vibrates!

With large pucks like the one from Clearaudio i would be also worried about angular errors.

The center hole must be absolutely rectangular.

Sony CDP ES Series

Hi, I am looking to find a new/replacement puck for my CD transport. Anyone got any ideas?

Hi, I am looking to find a new/replacement puck for my CD transport. Anyone got any ideas?

I finally ended up in making the stabilizer linked below.

This aluminium stabilizer became bigger for better damping but still

weights half of the original brass stabilizer pictured before.

The final version has a center bearing from Iglidur

for better fit. The milling tolerance is 0,01mm.

The surface is sandblasted (using glass pearls) with a 25µm

thick anodizing layer. The temper of the layer is comparable

to corundum. The bottom is covered with 0,5mm

velvet to protect the label side of the disc.

NEW Stabilizer for Sony´s Fixed Pickup Mechanism presented on a CDP-X5000

The stabilizer is available for €100,- plus shipment.

This aluminium stabilizer became bigger for better damping but still

weights half of the original brass stabilizer pictured before.

The final version has a center bearing from Iglidur

for better fit. The milling tolerance is 0,01mm.

The surface is sandblasted (using glass pearls) with a 25µm

thick anodizing layer. The temper of the layer is comparable

to corundum. The bottom is covered with 0,5mm

velvet to protect the label side of the disc.

NEW Stabilizer for Sony´s Fixed Pickup Mechanism presented on a CDP-X5000

The stabilizer is available for €100,- plus shipment.

Last edited:

Sony CD Puck

Hi,

I finally got a reply from Audio Synthesis (who make the CD transport, with the Sony Mech' which I use). I need a replacement (or new equivalent) for a Sony CDP-X3000 mech'. The Sony Part number is/was X-4947-761-1

The way the AS Transcend Decade is constructed, it HAS to be the same dimensions as the original 'puck'. Anyway, I use the pucks with the Marigo Labs CD 'Mats' glued on. I am buying the latest one from Ron Hedrich, so I would like to use a new puck with it.

$100 cost is no object!

Hi,

I finally got a reply from Audio Synthesis (who make the CD transport, with the Sony Mech' which I use). I need a replacement (or new equivalent) for a Sony CDP-X3000 mech'. The Sony Part number is/was X-4947-761-1

The way the AS Transcend Decade is constructed, it HAS to be the same dimensions as the original 'puck'. Anyway, I use the pucks with the Marigo Labs CD 'Mats' glued on. I am buying the latest one from Ron Hedrich, so I would like to use a new puck with it.

$100 cost is no object!

Hi,

I can send you some shots of the puck, if you like, along with measuring the dimensions... I am new to this forum though, so maybe via email. Anyway, please let me know?

I can send you some shots of the puck, if you like, along with measuring the dimensions... I am new to this forum though, so maybe via email. Anyway, please let me know?

I think, the diameter of the shaft in the X3000 is different from the X5000.

But maybe I can adapt it. Send you p.m.

But maybe I can adapt it. Send you p.m.

- Status

- Not open for further replies.

- Home

- Source & Line

- Digital Source

- Sony Fixed Pickup Mechanism - a Sensible Modification