Hello,

I currently have 4 Hammond 229C30 pcb transformers used in the PSU of the line amp. When the preamp is turned on, one can clearly hear the transformers humming.

- These transformers are 24VA each, load for each xfmr is about 10VA.

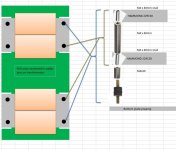

- See picture of how the assembly looks like. Bottom PCB is mounted to preamp chasssis used damped (rubber) distance holders.

- Downstream of the preamp is a mains filter with DC-blocker installed.

I'm looking for better alternatives than the Hammond 229 series. I've read on this forum that also other users of these 229 series experience mechanical humm.

Dual bobbin is proposed to be ideal in low power equipment, where toroidal's are not due to too good coupling between primary and secundary.

1. Block Low profile - FL series : https://www.block.eu/en_EN/products/transformers/pcb-transformers/

2. Toroidy Supreme audio toroidal: https://sklep.toroidy.pl/en_US/c/Toroidal-transformers-SUPREME-AUDIO-GRADE-V2/99

3. ??? other, better ideas?

I currently have 4 Hammond 229C30 pcb transformers used in the PSU of the line amp. When the preamp is turned on, one can clearly hear the transformers humming.

- These transformers are 24VA each, load for each xfmr is about 10VA.

- See picture of how the assembly looks like. Bottom PCB is mounted to preamp chasssis used damped (rubber) distance holders.

- Downstream of the preamp is a mains filter with DC-blocker installed.

I'm looking for better alternatives than the Hammond 229 series. I've read on this forum that also other users of these 229 series experience mechanical humm.

Dual bobbin is proposed to be ideal in low power equipment, where toroidal's are not due to too good coupling between primary and secundary.

1. Block Low profile - FL series : https://www.block.eu/en_EN/products/transformers/pcb-transformers/

2. Toroidy Supreme audio toroidal: https://sklep.toroidy.pl/en_US/c/Toroidal-transformers-SUPREME-AUDIO-GRADE-V2/99

3. ??? other, better ideas?

Attachments

Jan, How does one mechanically isolate the transformer when its body mounted pins are soldered directly to the board? Thanks.

The main vibration is in the core. Isolating the core from the PCB helps lower the noise. There will be some via the pins, yes you are right, but there's some flexibility in the pin connection to the xfrmr, and the xfrmr vibration doesn't couple 100% to the pins.

But you will not get rid of it completely, agreed.

Best would be to isolate the xfrmr and connect via short wires.

Jan

But you will not get rid of it completely, agreed.

Best would be to isolate the xfrmr and connect via short wires.

Jan

That won't work, core will always vibrate, pretty much impossible to forcefully damp.

You could enclose the xfrmr in a sound damping enclosure like a rubber or foam box.

Prevent as much as possible coupling of the vibrations to the environment.

But mechanically damping it by force won't work.

Jan

You could enclose the xfrmr in a sound damping enclosure like a rubber or foam box.

Prevent as much as possible coupling of the vibrations to the environment.

But mechanically damping it by force won't work.

Jan

it's like a hairclipper ....a magnetic mass excited by a 60 hz coil...stop the mass moving and you reduce the vibration....and undoubtedly the pcb is acting like a diaphragm.

is there no possibility of relocating the standoffs so they support the transformer cores?

is there no possibility of relocating the standoffs so they support the transformer cores?

I see something worrying in the DS:

For the primary, it is inherently fulfilled, but if the secondaries are used in a CT configuration (not with 2 x three wires fully paralleled), some imbalance will occur during the rectification and cause buzzing.

To test the actual configuration, use the full secondary voltage on a passive, linear load of 24VA: if it buzzes, it means the transformer is lose, if it doesn't, the internal wiring configuration is not well suited to CT rectifiers

In this type of dual bobbin/winding transformer, all the equivalents windings have to be balanced, not only on average, but also dynamically, during any instant of the mains cycle.Low primary to secondary coupling, balanced windings, no electrostatic shield required

For the primary, it is inherently fulfilled, but if the secondaries are used in a CT configuration (not with 2 x three wires fully paralleled), some imbalance will occur during the rectification and cause buzzing.

To test the actual configuration, use the full secondary voltage on a passive, linear load of 24VA: if it buzzes, it means the transformer is lose, if it doesn't, the internal wiring configuration is not well suited to CT rectifiers

The Talema potted toroids that I have used are silent. https://www.digikey.com/en/products/detail/talema-group-llc/70063K/3881322

Ed

Ed

HI Elvee,I see something worrying in the DS:

In this type of dual bobbin/winding transformer, all the equivalents windings have to be balanced, not only on average, but also dynamically, during any instant of the mains cycle.

For the primary, it is inherently fulfilled, but if the secondaries are used in a CT configuration (not with 2 x three wires fully paralleled), some imbalance will occur during the rectification and cause buzzing.

To test the actual configuration, use the full secondary voltage on a passive, linear load of 24VA: if it buzzes, it means the transformer is lose, if it doesn't, the internal wiring configuration is not well suited to CT rectifiers

As mentioned above, I have connected both secundaries in series, to have 30Vac. I don't use a center tap.

Accidentally posted my comment on transformers in the wrong thread:

https://www.diyaudio.com/community/...ad-current-rule-of-thump.391759/#post-7167171

https://www.diyaudio.com/community/...ad-current-rule-of-thump.391759/#post-7167171

I've used about 8 of these flat-pack transformers, by Hammond, Signal Transformer, and Triad. They are all PCB-mounted with no additional support for the core.

One preamp is a dual mono design with two 40v, 300mA flat pack transformers in a clamshell configuration, so the transformers are separated about 1" and with the top of one facing the top of the other. I'm wondering if you're getting some induced hum by the close vertical and horizontal spacing. My dual mono preamp does have a bit of hum, but it is inaudible from a foot away, and only audible if there is no other sound in the room.

My other use of these includes a high-quality MC head amp with the transformer, rectifier and filters in a separate case. That is a 6-0-6 200mA transformer, and there is no hum at all. Same with my other power supplies built using flat-pack transformers.

One preamp is a dual mono design with two 40v, 300mA flat pack transformers in a clamshell configuration, so the transformers are separated about 1" and with the top of one facing the top of the other. I'm wondering if you're getting some induced hum by the close vertical and horizontal spacing. My dual mono preamp does have a bit of hum, but it is inaudible from a foot away, and only audible if there is no other sound in the room.

My other use of these includes a high-quality MC head amp with the transformer, rectifier and filters in a separate case. That is a 6-0-6 200mA transformer, and there is no hum at all. Same with my other power supplies built using flat-pack transformers.

core to core without then being attached to the chassis would be a half measure.

or am i misunderstanding your drawing...? would relocating the standoffs cause any problems with respect to the foil traces on the PCB?

or am i misunderstanding your drawing...? would relocating the standoffs cause any problems with respect to the foil traces on the PCB?

I would pull one transformer and put leads on it, rest it on an eraser or some other rubber thingy and see if it can be heard. If not, do them all that way , or flip the boards over and hang the transformers from the boards with something like silicone polymer fan mounts through the existing corner holes on the core. TIme consuming but likely less expensive and wasteful than buying four new unproven alternates.

ALSO

Perhaps not applicable here but it seems a good time to ask a question.

I remember years ago running across text on a web page to the effect that mechanical hum can result from under-loading a power transformer. I don't think I've ever seen this myself but as the OP is running his at under half their current rating the idea came to mind. Thanks.

ALSO

Perhaps not applicable here but it seems a good time to ask a question.

I remember years ago running across text on a web page to the effect that mechanical hum can result from under-loading a power transformer. I don't think I've ever seen this myself but as the OP is running his at under half their current rating the idea came to mind. Thanks.

Are these boards in free air or a box? Potting them in a thermally conductive potting compound might help. Mount the boards individually on sandwich mounts to aluminum plate. (Mass is helpful.)

As someone pointed out Talema makes very quiet toroids, there are others. They may be hard to get at the moment. Use common mode chokes on the primary side if using toroids.

As someone pointed out Talema makes very quiet toroids, there are others. They may be hard to get at the moment. Use common mode chokes on the primary side if using toroids.

Something to note, the cores of these transformers are not intended to be supported by anything but the bobbins they are mounted in. Using metal screws to clamp them to a metal chassis may result in eddy currents in the chassis.

Another type to consider are R core transformers, they're generally very quiet in operation and offer somewhat better efficiency than EI and better isolation from line borne noise than toroids. (Decent inrush behavior as well.)

Another type to consider are R core transformers, they're generally very quiet in operation and offer somewhat better efficiency than EI and better isolation from line borne noise than toroids. (Decent inrush behavior as well.)

- Home

- Design & Build

- Parts

- Silent transformers for use in preamp