Apologies up front if this is a little long-winded. I'm trying to be succinct, but I don't want to leave out something important unwittingly.

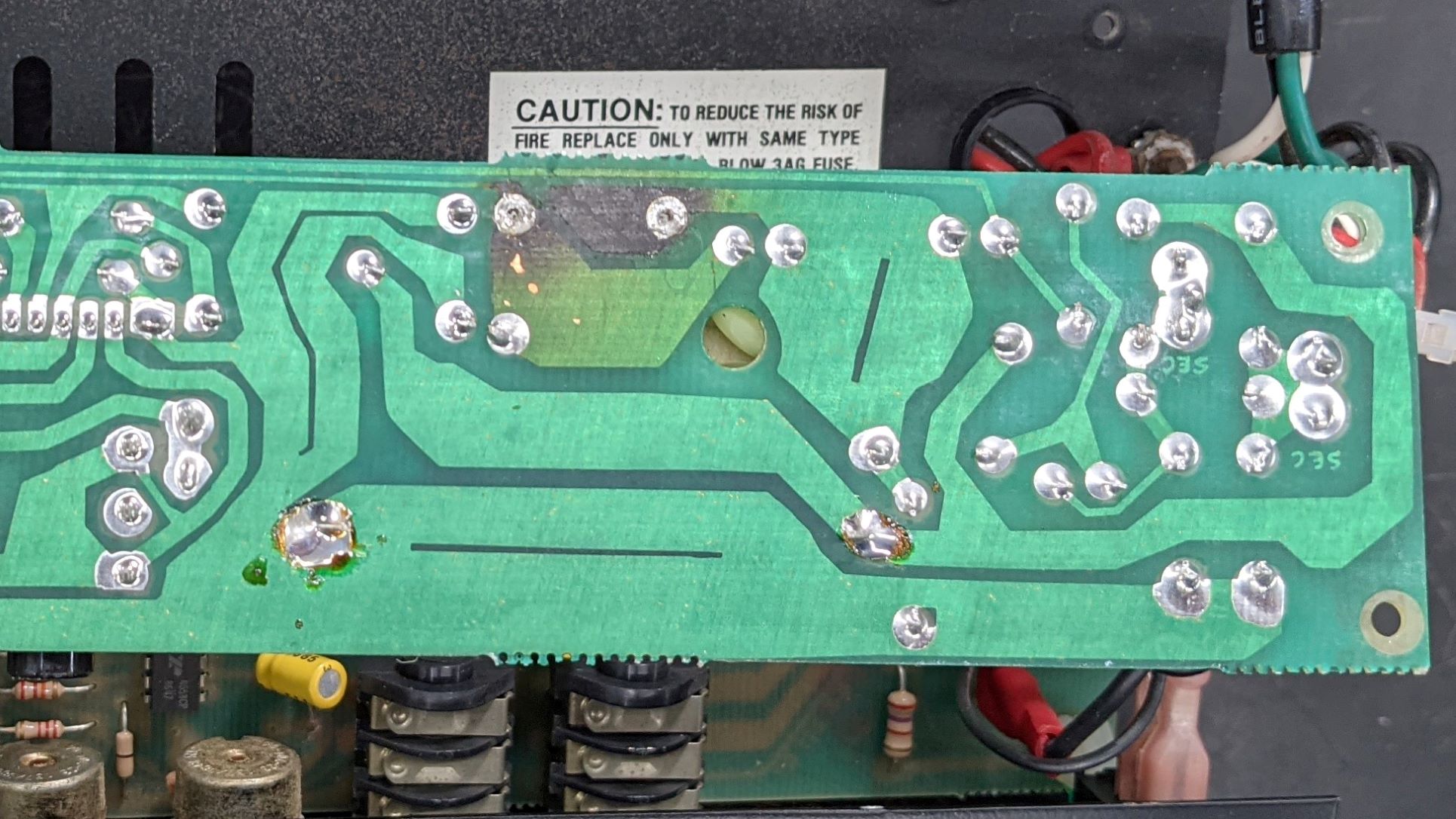

I've got a Crate G-40C guitar amp I bought new back in the mid-80's. Sometime in the first half of '93 it stopped working after an hour or so of use in a hot rehearsal room. I thought at the time it might have blown a fuse so I opened it up for a look. I didn't find any blown fuses, but I did find some scorching on the bottom of the rear PCB under what I think may have been a diode or resistor.

I say "think" because my troubleshooting efforts stopped there back in 1993. I have a faint recollection of de-soldering whatever was located there with the intent of trying to find a replacement, but I ended up just bagging all the loose parts, screws, etc. and setting it aside until I had more time to investigate further. Well, here I am now 28 years later picking up where I left off except all I have in the bag of loose parts is the four long machine screws used to hold the amp chassis in the cabinet and a short 4A/125V fuse of unknown origin. Conspicuously absent from the bag is whatever component I removed from the rear PCB (along with the screws and stand-offs to mount the rear PCB in the metal chassis and the three screws used to secure the IC heatsink to the chassis).

Now, I have a remedial understanding of electronic components (capacitors store energy, resistors restrict, etc.) and I'm comfortable with through-hole soldering. But that's about it. Having said that, I figured checking the schematics would be the best place to start trying to identify the missing mystery component.

The manual that came with the amp has scaled down schematics, but I found updated versions online here which actually has a diagram of the PCB layout along with the schematics.

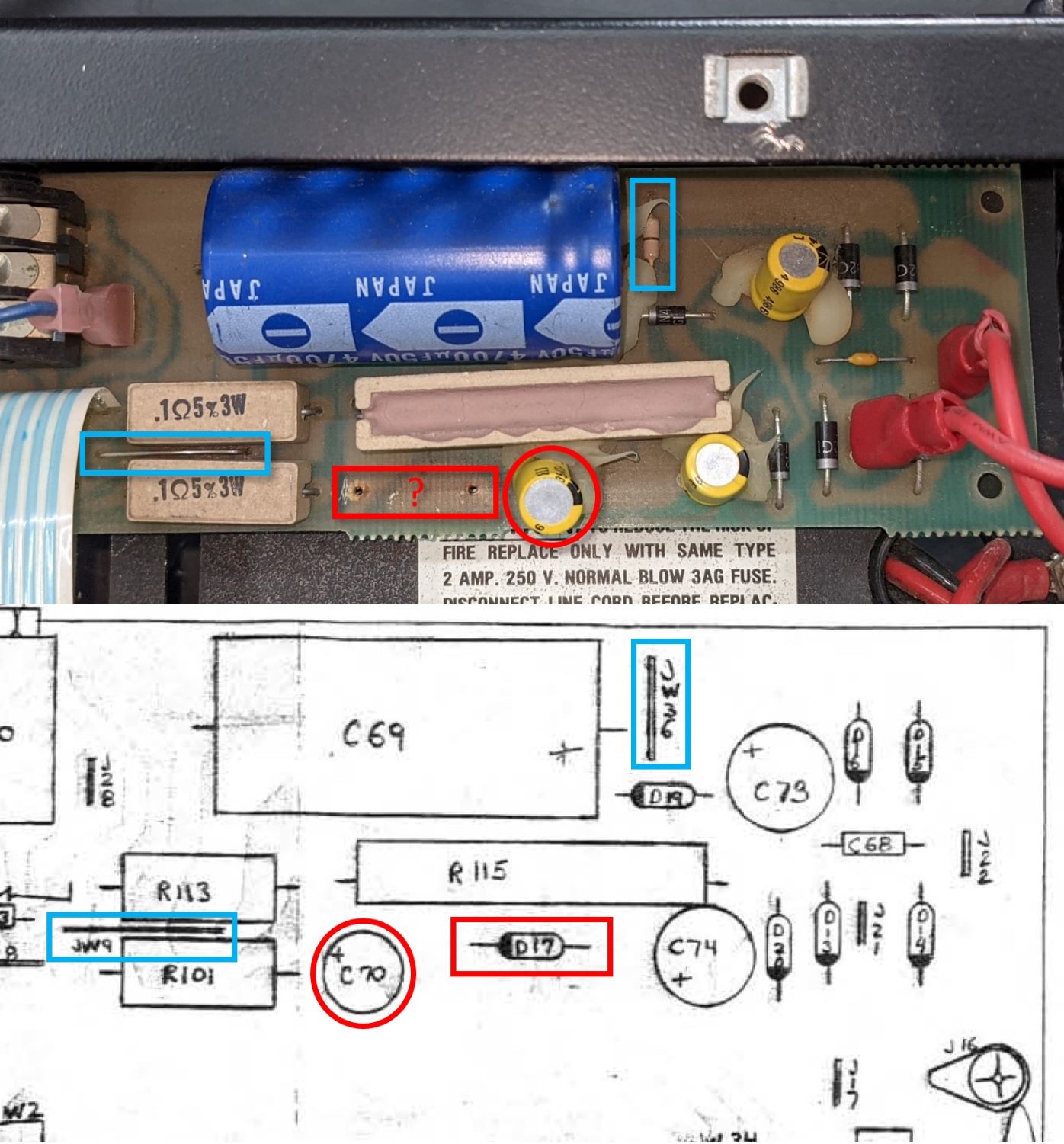

Now the fun part: As you can see in the pic below, the layout on my PCB (top) isn't the same as what's shown in the Pictorial Assy layout (bottom).

There are 2 differences I have concerns about:

Lastly, one of the ribbon cables connecting the PCBs has started to delaminate.

Does this need to be replaced before I plug it back in and turn it on? If so, will regular computer ribbon cable suffice, or is there something specific I should replace it with?

Any help, comments, suggestions are much appreciated.

I've got a Crate G-40C guitar amp I bought new back in the mid-80's. Sometime in the first half of '93 it stopped working after an hour or so of use in a hot rehearsal room. I thought at the time it might have blown a fuse so I opened it up for a look. I didn't find any blown fuses, but I did find some scorching on the bottom of the rear PCB under what I think may have been a diode or resistor.

I say "think" because my troubleshooting efforts stopped there back in 1993. I have a faint recollection of de-soldering whatever was located there with the intent of trying to find a replacement, but I ended up just bagging all the loose parts, screws, etc. and setting it aside until I had more time to investigate further. Well, here I am now 28 years later picking up where I left off except all I have in the bag of loose parts is the four long machine screws used to hold the amp chassis in the cabinet and a short 4A/125V fuse of unknown origin. Conspicuously absent from the bag is whatever component I removed from the rear PCB (along with the screws and stand-offs to mount the rear PCB in the metal chassis and the three screws used to secure the IC heatsink to the chassis).

Now, I have a remedial understanding of electronic components (capacitors store energy, resistors restrict, etc.) and I'm comfortable with through-hole soldering. But that's about it. Having said that, I figured checking the schematics would be the best place to start trying to identify the missing mystery component.

The manual that came with the amp has scaled down schematics, but I found updated versions online here which actually has a diagram of the PCB layout along with the schematics.

Now the fun part: As you can see in the pic below, the layout on my PCB (top) isn't the same as what's shown in the Pictorial Assy layout (bottom).

There are 2 differences I have concerns about:

- The diode and capacitor at the front edge (noted in red) are not in the same location on the board as on the Pictorial Assy. The capacitor (C70) on the board does match the specs in the parts schedule (47/35V). Also, it appears my missing mystery part is a Zener diode (D17, listed as "1N5357A, 21-557-01" in the parts schedule).

- The component (JW36 - noted in blue) at the back edge of the board is supposed to be a jumper wire (like JW9, also noted in blue) but appears to be a resistor. It (JW36) measures 0 ohms on the multimeter, so it's a 0 ohm resistor? Not sure what's going on there.

Lastly, one of the ribbon cables connecting the PCBs has started to delaminate.

Does this need to be replaced before I plug it back in and turn it on? If so, will regular computer ribbon cable suffice, or is there something specific I should replace it with?

Any help, comments, suggestions are much appreciated.

Greetings

Know the feeling of letting something sit for a long time.

The Zener diode is 20 volt - 5 watt. This puppy was making heat and likely was installed right against the PC board.

What I would end up doing is get a new Zener, allow it to stand off the PC to reduce the over heating on the PC board. And on the overheated solder pads...I would carefully scrape down to bare copper near the holes - and scrape area to solder the leads flat to the traces, and if the device leads are long enough, run them over to the nearest connection on that trace. Hope that makes sense.

The electrolytic is in parallel with the Zener and band end of the Zener would connect to the positive lead of the electrolytic.

The component with one black (zero in color code) band is indeed a "zero ohm resistor". You will see more of those in that amp.

I looked in my files and do not see the service file on this amp.

If you have the schematic - establish the resistors feeding the Zener are close to the indicated value.

That ribbon cable - I have not seen that before in my 50 years of bench service.

If the conductors are sticking ok on a side of the ribbon - and not broken or touching, I would at least try the amp.

Of course establish continuity one board to the next on each conductor...

Good luck

Hope you get it working

For a period of time I was employed at a small business and part of my duties was an authorized SLM service location. Crate, Audio Centron and Ampeg. Left that place some years ago...

Still have a shop at my home...

Know the feeling of letting something sit for a long time.

The Zener diode is 20 volt - 5 watt. This puppy was making heat and likely was installed right against the PC board.

What I would end up doing is get a new Zener, allow it to stand off the PC to reduce the over heating on the PC board. And on the overheated solder pads...I would carefully scrape down to bare copper near the holes - and scrape area to solder the leads flat to the traces, and if the device leads are long enough, run them over to the nearest connection on that trace. Hope that makes sense.

The electrolytic is in parallel with the Zener and band end of the Zener would connect to the positive lead of the electrolytic.

The component with one black (zero in color code) band is indeed a "zero ohm resistor". You will see more of those in that amp.

I looked in my files and do not see the service file on this amp.

If you have the schematic - establish the resistors feeding the Zener are close to the indicated value.

That ribbon cable - I have not seen that before in my 50 years of bench service.

If the conductors are sticking ok on a side of the ribbon - and not broken or touching, I would at least try the amp.

Of course establish continuity one board to the next on each conductor...

Good luck

Hope you get it working

For a period of time I was employed at a small business and part of my duties was an authorized SLM service location. Crate, Audio Centron and Ampeg. Left that place some years ago...

Still have a shop at my home...

Lord, I had one of those Crate G-40C amps and it drove me absolutely NUTS! It had a intermittent power supply that would shut down on a whim and for the life of me I could NOT locate the fault! I finally just donated it to Goodwill. If I were to have it again, I think I would just REPLACE the power supply with something more reliable. Otherwise, I thought it was a damn good-sounding amp (for SS anyway) with a lot of cool features.

I think I understand.And on the overheated solder pads...I would carefully scrape down to bare copper near the holes - and scrape area to solder the leads flat to the traces, and if the device leads are long enough, run them over to the nearest connection on that trace. Hope that makes sense.

- Carefully scrape the area round the through-holes down to bare copper.

- Find the nearest connection along the trace on each side of the diode and carefully scrape the solder mask down to bare copper along that path.

- Install the diode and bend the diode leads to follow that path.

- Solder the diode leads to the bare copper through holes and path to the nearest connection.

Does that look right?

Also, will any 20V 5W Zener diode suffice? I'm having trouble finding a 1N5357A specifically. (Evidently 1N5357B's are everywhere.)

Many thanks for the help!

Greetings

Your photo with the red lines is exactly what I meant. Yes.

And if the leads reach the other component solder connection - do that.

Any 5 watt, 20 volt zener should be ok.

Have seen scorched PC boards many times.

And what you are doing is what I have done each time.

Leaving air space between the zener and the top of the PC will give some air distance....

Carry on

Your photo with the red lines is exactly what I meant. Yes.

And if the leads reach the other component solder connection - do that.

Any 5 watt, 20 volt zener should be ok.

Have seen scorched PC boards many times.

And what you are doing is what I have done each time.

Leaving air space between the zener and the top of the PC will give some air distance....

Carry on

That is unfortunate. Makes me wonder what the heck was going on. There are some problems from time to time that drive us crazy....yesLord, I had one of those Crate G-40C amps and it drove me absolutely NUTS! It had a intermittent power supply that would shut down on a whim and for the life of me I could NOT locate the fault! I finally just donated it to Goodwill. If I were to have it again, I think I would just REPLACE the power supply with something more reliable. Otherwise, I thought it was a damn good-sounding amp (for SS anyway) with a lot of cool features.

Crate had some decent amps over the years.

I recall a time when a new Crate amp reacted with greatly increased treble, when turning up the reverb. I contacted SLM and offered a solution to the issue, but was ignored. Oh well. I have had to correct engineering mistakes over the years here and there....

I am not an engineer but sometimes one of us are able to help them out.

Update on the G40C resurrection project - it's getting power now, but that's uncovered some more issues.

I got the Zener diode installed (1N5357B; 1N5357A's were nowhere to be found). The leads were long enough to make it to the nearest component on each side of the trace.

I checked the delaminated ribbon cable, and it had continuity on each lead.

I did see some scratches on the back of the rear PCB from a sheet metal screw sticking up through the chassis which probably happened while I was working on it without the stand-offs in place. Two of the solder joints looked iffy, so I reflowed them. I was worried I might have inadvertently bridged them, but looking at the schematics it appears they're supposed to be connected (JW28 taking D21 to ground on one side and R94 and R105 on the other).

When I was reinstalling the chassis in the cabinet I realized I had zero recollection of which wires were connected to which speaker. Using the Pictorial Assy drawing I matched the wire color to PCB tab to the schematic (Red-J25-Left, White-J26-Right, Black-J27-Left, and Blue-J28-Right), but I couldn't figure out which were positive/negative just by looking at the schematic. I guessed J25 & J26 were the positives since they also fed what appeared to be the tips on the Left/Right Line Out jacks. Someone let me know if I got that backwards.

With everything reassembled I plugged it in, connected a guitar, and turned it on. Thankfully, no magic smoke was released. However...

Now the weird parts:

I got the Zener diode installed (1N5357B; 1N5357A's were nowhere to be found). The leads were long enough to make it to the nearest component on each side of the trace.

I checked the delaminated ribbon cable, and it had continuity on each lead.

I did see some scratches on the back of the rear PCB from a sheet metal screw sticking up through the chassis which probably happened while I was working on it without the stand-offs in place. Two of the solder joints looked iffy, so I reflowed them. I was worried I might have inadvertently bridged them, but looking at the schematics it appears they're supposed to be connected (JW28 taking D21 to ground on one side and R94 and R105 on the other).

When I was reinstalling the chassis in the cabinet I realized I had zero recollection of which wires were connected to which speaker. Using the Pictorial Assy drawing I matched the wire color to PCB tab to the schematic (Red-J25-Left, White-J26-Right, Black-J27-Left, and Blue-J28-Right), but I couldn't figure out which were positive/negative just by looking at the schematic. I guessed J25 & J26 were the positives since they also fed what appeared to be the tips on the Left/Right Line Out jacks. Someone let me know if I got that backwards.

With everything reassembled I plugged it in, connected a guitar, and turned it on. Thankfully, no magic smoke was released. However...

- When the power switch is flipped on there is a loud pop/thump, a loud hum for ~1 second and then a quieter, constant hum which, to my recollection at least, seems louder than I remember, almost like something isn't grounded somewhere.

- There is some static when turning the Channel A Level knob, the Channel B Volume, Low, & High knobs, and the Reverb Depth knob. Some of the static went away after working the knobs back and forth a bit, but the Channel A Level and Channel B Volume knobs are still particularly noisy.

Now the weird parts:

- The speaker (and headphone) volume will drop intermittently either all or most of the way down for random lengths of time every minute or two. Manipulating the controls does not seem to affect it, but cycling the power on the amp will sometimes resolve it for a minute or so.

- The amp will intermittently switch channels between Channel A and B regardless of which channel the Channel Select switch is set to. It stays on Channel B 80% of the time and will randomly switch to Channel A intermittently but never for more than 30-60 seconds. Actuating the Channel Select switch does not seem to have any affect, however the corresponding channel LED will light correctly when that channel is processing the signal (i.e., the Channel A LED is lit when the signal is going through Channel A and vise versa). Also, if Channel A is selected when the amp is turned on the Channel A LED will light up briefly then immediately goes out and the Channel B LED comes on.

- Neither problem appears to be affected by manipulating the controls, using either input, or using the headphone jack.

STart with the jacks. The footswitch jack changes channels. WHen you are NOT using it, the shunt contacts in the jack complete the circuit. If those contacts are dirty (electrically) then they can act as open. clean them.

FX lop jacks, same story. When you are NOT using them, the return jack shunt contacts carry the ssignal past the loop. They get dirty and you get this symptom. Clean them.

FX lop jacks, same story. When you are NOT using them, the return jack shunt contacts carry the ssignal past the loop. They get dirty and you get this symptom. Clean them.

That makes perfect sense. Is it sufficient to use something like a quick-dry contact cleaner (link) or one of the DeoxIT D-series cleaners? Or is some type of mechanical cleaning a better option?STart with the jacks. The footswitch jack changes channels. WHen you are NOT using it, the shunt contacts in the jack complete the circuit. If those contacts are dirty (electrically) then they can act as open. clean them.

FX lop jacks, same story. When you are NOT using them, the return jack shunt contacts carry the ssignal past the loop. They get dirty and you get this symptom. Clean them.

Also, is there any down-side to cleaning all of the jacks while I've got it apart again?

Hello again sirUpdate on the G40C resurrection project - it's getting power now, but that's uncovered some more issues.

I got the Zener diode installed (1N5357B; 1N5357A's were nowhere to be found). The leads were long enough to make it to the nearest component on each side of the trace.

View attachment 1010552

View attachment 1010554

I checked the delaminated ribbon cable, and it had continuity on each lead.

I did see some scratches on the back of the rear PCB from a sheet metal screw sticking up through the chassis which probably happened while I was working on it without the stand-offs in place. Two of the solder joints looked iffy, so I reflowed them. I was worried I might have inadvertently bridged them, but looking at the schematics it appears they're supposed to be connected (JW28 taking D21 to ground on one side and R94 and R105 on the other).

View attachment 1010555

When I was reinstalling the chassis in the cabinet I realized I had zero recollection of which wires were connected to which speaker. Using the Pictorial Assy drawing I matched the wire color to PCB tab to the schematic (Red-J25-Left, White-J26-Right, Black-J27-Left, and Blue-J28-Right), but I couldn't figure out which were positive/negative just by looking at the schematic. I guessed J25 & J26 were the positives since they also fed what appeared to be the tips on the Left/Right Line Out jacks. Someone let me know if I got that backwards.

With everything reassembled I plugged it in, connected a guitar, and turned it on. Thankfully, no magic smoke was released. However...

- When the power switch is flipped on there is a loud pop/thump, a loud hum for ~1 second and then a quieter, constant hum which, to my recollection at least, seems louder than I remember, almost like something isn't grounded somewhere.

- There is some static when turning the Channel A Level knob, the Channel B Volume, Low, & High knobs, and the Reverb Depth knob. Some of the static went away after working the knobs back and forth a bit, but the Channel A Level and Channel B Volume knobs are still particularly noisy.

Now the weird parts:

I really don't know where to start troubleshooting this. Could the delaminated ribbon cable and/or the scratchy knobs be part of the problem? Where do I start? All help, comments, suggestions are much appreciated!

- The speaker (and headphone) volume will drop intermittently either all or most of the way down for random lengths of time every minute or two. Manipulating the controls does not seem to affect it, but cycling the power on the amp will sometimes resolve it for a minute or so.

- The amp will intermittently switch channels between Channel A and B regardless of which channel the Channel Select switch is set to. It stays on Channel B 80% of the time and will randomly switch to Channel A intermittently but never for more than 30-60 seconds. Actuating the Channel Select switch does not seem to have any affect, however the corresponding channel LED will light correctly when that channel is processing the signal (i.e., the Channel A LED is lit when the signal is going through Channel A and vise versa). Also, if Channel A is selected when the amp is turned on the Channel A LED will light up briefly then immediately goes out and the Channel B LED comes on.

- Neither problem appears to be affected by manipulating the controls, using either input, or using the headphone jack.

The way you did the zener on elevation and the bottom of PC connections is exactly as I suggested.

Enzo is quite correct on the issues with jacks, that often have contacts that make or break, when inserting a plug.

Very common issue.

You asked about de-ox (Caig for instance - is all I use for de-ox and also they have spray for rotary pot and slider cleaner/ with lube)

Many odd issues are corrected when using the de-ox on any jacks like in your amp....

They tarnish almost like silverware - especially problems happen with jacks that have through connection that must exist with no plug inserted.

Your pots would benefit with something like Caig cleaner/lube for potentiometers.

Using straight de-ox with no lube - I would not do that. You want lubrication between the pot wiper and carbon track inside.

Stay away from stuff like WD-40. I have had people do that, then I get the item and explain that was a bad idea. WD is a solvent.

A thump when turning on is probably normal, if an amp like this has no delay relay on the speaker feed.

The hum ? Are you trying this out with the chassis floating rather than mounted in and at least snug nuts on pot shafts and installed PC mount screws ?

Also - possible some DC offset at the output. A bit of offset is not normally an issue, but more than lets say 50 mV - give or take - could indicate an issue in the driver/output section.

Wish the best

Carry on

That makes perfect sense. Is it sufficient to use something like a quick-dry contact cleaner (link) or one of the DeoxIT D-series cleaners? Or is some type of mechanical cleaning a better option?

Both 🙂

A little cleaner fluid squirt/drop into the contact surface PLUS insert/pull plug 10-20 times so the mechanical rubbing action helps remove crud.

When I clean Cliff-type jacks like that, I use Deoxit, but I also use mechanical means. I have some old GC burnishers that work great, but lacking that, I slice a narrow strip off the end of a business card. Plug into the jack to open the contacts, and place the strip between the contacts. Remove the plug. Now the contacts close around the strip of stiff paper. Gently pull the strip out, or even push it in and out a couple times. Clean contacts.

I learned that years ago working on relays. In the field a business card or the corner of a match book. But who has match books these days?

GC burnishers come in two sizes. The "standard" size is 1/4" which is too large. The smaller is like 3/16" I think, and it fits neatly between the plastic ridges of the Cliff jack.

I learned that years ago working on relays. In the field a business card or the corner of a match book. But who has match books these days?

GC burnishers come in two sizes. The "standard" size is 1/4" which is too large. The smaller is like 3/16" I think, and it fits neatly between the plastic ridges of the Cliff jack.

For more brutal cleaning: gun-shop, .22 caliber (rimfire) gun cleaning brush. This is a tiny brass wire brush. It is convenient to get the handle too. But don't buy a Complete Kit (or if you must, get "pistol" not "rifle", since you don't need extenders). Brush $3, handle $3, kit $13.

https://www.proshotproducts.com/22-Cal-Rimfire-Rifle-Brush_p_360.html

https://www.brownells.com/gun-clean...andard-line-bronze-bore-brushes-prod1277.aspx

I say "rimfire" because that is what I used to use (large patchbay) and it was a mild draggy fit (I guess the brush is 0.25"+ to get heavy drag in a 0.223" barrel). Since then a few other '.22' calibers, military centerfire, have become common; I have not used those.

https://www.proshotproducts.com/22-Cal-Rimfire-Rifle-Brush_p_360.html

https://www.brownells.com/gun-clean...andard-line-bronze-bore-brushes-prod1277.aspx

I say "rimfire" because that is what I used to use (large patchbay) and it was a mild draggy fit (I guess the brush is 0.25"+ to get heavy drag in a 0.223" barrel). Since then a few other '.22' calibers, military centerfire, have become common; I have not used those.

Last edited:

Those work great for cleaning the bore and contacts, but they don't get to the shunt contacts which are off to the side a little.

Many, many thanks for all the comments and suggestions, guys. This is truly an amazing group of helpful folks here.

I've got some Caig DeoxIT (DN5S-2N) on order to clean up the jacks and the pots, and I've got a huge stack of old business cards I can use to try cleaning the contacts.

Also, to answer your question djcgtr, I'm testing with everything installed in the cabinet (e.g., PCB mounted to the chassis with standoffs, all nuts & screws snug, etc.). Interesting side story: Remember the parts missing from the bag (rear PCB standoffs, screws, etc.)? I found them all when I was going through my fastener bins looking for suitable replacements. Evidently, they got separated from the bag sometime over the last 28 years, and I recycled them without even realizing it. My luck does not typically run in that direction....

I've got some Caig DeoxIT (DN5S-2N) on order to clean up the jacks and the pots, and I've got a huge stack of old business cards I can use to try cleaning the contacts.

Also, to answer your question djcgtr, I'm testing with everything installed in the cabinet (e.g., PCB mounted to the chassis with standoffs, all nuts & screws snug, etc.). Interesting side story: Remember the parts missing from the bag (rear PCB standoffs, screws, etc.)? I found them all when I was going through my fastener bins looking for suitable replacements. Evidently, they got separated from the bag sometime over the last 28 years, and I recycled them without even realizing it. My luck does not typically run in that direction....

Quote from The Meridian: "sometime over the last 28 years"

Not much doubt on pots and jack contacts being compromised a bit after that period of time....to say the least.

De ox and lube is quite in order

Edge connectors and any plugs/sockets benefit with de ox also.

Along with the mechanical aspect of in and out, connect/disconnect etc

Much good additional info has been offered.

Yes, this site has many very qualified individuals

A wealth of experience and insight dwells within.

Not much doubt on pots and jack contacts being compromised a bit after that period of time....to say the least.

De ox and lube is quite in order

Edge connectors and any plugs/sockets benefit with de ox also.

Along with the mechanical aspect of in and out, connect/disconnect etc

Much good additional info has been offered.

Yes, this site has many very qualified individuals

A wealth of experience and insight dwells within.

While waiting for the DeoxIT to arrive I was looking at the pots and trying to figure out how to get the DeoxIT inside. Is there a best practice for that? There's no openings I can see except on the bottom next to the PCB. Is it enough to just find a seam or crevice to spray the DeoxIT into to pot? Would one blast suffice? Do I need to be actuating the pot when I spray it? Do I need to worry about spraying too much?

I believe there is space at the pins of the pot by the PC board.While waiting for the DeoxIT to arrive I was looking at the pots and trying to figure out how to get the DeoxIT inside. Is there a best practice for that? There's no openings I can see except on the bottom next to the PCB. Is it enough to just find a seam or crevice to spray the DeoxIT into to pot? Would one blast suffice? Do I need to be actuating the pot when I spray it? Do I need to worry about spraying too much?

I set the adjustable spray to minimum and short burst into the bottom of pot - up inside of it. This has lube in in it - right ?

I take a pair of needle nose and create a gradual bend in the end of the nozzle extension, to make a curve there - to help get the spray into the pot or switches or other...

After a short burst, then rotate the pot a bit. Do not need a ton of it - not spray paint it - ha

You may find a bit more is needed if still scratchy sounding.

If the carbon trace inside has gotten worn or damaged, then no amount of de ox will fix that...

Hope goes well

Carry on

OK, so you set the chassis open side up on the bench, and the opening on the pots are on the bottom, right? So you'd have to spray up into them. So turn the chassis open side down. Now the pot holes are up on top. But they are under the chassis. Lift one end of the amp up off the bench, like a 45 degree angle. Now look up under there. I hold the tip of my Deoxit spray tube right against the pot wafer right over that hole. Gentle allow a drizzle out the tube tip. It will flow down into th pot. As dj said, doesn't take a lot. If the end ones are inconvenient, lift the other end of the chassis and do the rest of the controls.

It only takes seconds to go down the row of controls. I may have to dodge components on the board that get in the way. OH well, life has its challenges.

It only takes seconds to go down the row of controls. I may have to dodge components on the board that get in the way. OH well, life has its challenges.

Lube is applied to the shafts not the contact surface of the pot.

Far as crackling of the controls and intermittent channel switching

and intermittent headphone and speaker signal.

as mentioned already the actual switching part of the jacks needs to be cleaned.

far as headphone jacks.

for a combo amp, usually the speaker is switched off if you plug in headphones.

so the actual speaker connection goes to the speaker through the headphone jack switching contacts

So the jack switching contacts need to be cleaned.

Many of the crate/ampeg combos with higher wattage

will eventually burn the headphone jack, and they are replaced.

far as the replaced zener, seems like most the burned pathways has been fixed with the jumpers

but there seems to be a small trace leading away from it, that still might not have good connection

Far as crackling of the controls and intermittent channel switching

and intermittent headphone and speaker signal.

as mentioned already the actual switching part of the jacks needs to be cleaned.

far as headphone jacks.

for a combo amp, usually the speaker is switched off if you plug in headphones.

so the actual speaker connection goes to the speaker through the headphone jack switching contacts

So the jack switching contacts need to be cleaned.

Many of the crate/ampeg combos with higher wattage

will eventually burn the headphone jack, and they are replaced.

far as the replaced zener, seems like most the burned pathways has been fixed with the jumpers

but there seems to be a small trace leading away from it, that still might not have good connection

Last edited:

- Home

- Live Sound

- Instruments and Amps

- Resurrecting 1980's Crate G-40C