I thought other Oracle owners might be interested in how I have successfully repowered my Oracle Delphi II.

The original motor was a 24 volt DC Papst which finally gave up the ghost last year after being a bit unsteady for some time.

A bit of research showed a hideously expensive upgraded motor was available from Oracle or I could go the Origin Live route which was also no bargain.

I happened to have a brand new Thorens synchronous motor available so figured I would have a go at installing this instead.

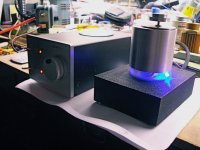

As you can see from the photos, installation was fairly straight forward using spacer sleeves onto the original mounting plate. I used the original pulley with a sleeve inside to compensate for the smaller shaft diameter.

This is powered by a DIY Armageddon Clone with a 500va toroidal transformer with the output reduced to 75 volts ac. I also experimented with various phase capacitors to achieve minimum motor vibration or cogging. The final value for this particular motor was 0.17uF resulting in the motor being dead silent with rock steady rpm.

OK it only has one speed but that's fine as the small number of 45s I have are played on my Thorens TD125.

It performs perfectly for a fraction of the cost of the other alternatives.

The original motor was a 24 volt DC Papst which finally gave up the ghost last year after being a bit unsteady for some time.

A bit of research showed a hideously expensive upgraded motor was available from Oracle or I could go the Origin Live route which was also no bargain.

I happened to have a brand new Thorens synchronous motor available so figured I would have a go at installing this instead.

As you can see from the photos, installation was fairly straight forward using spacer sleeves onto the original mounting plate. I used the original pulley with a sleeve inside to compensate for the smaller shaft diameter.

This is powered by a DIY Armageddon Clone with a 500va toroidal transformer with the output reduced to 75 volts ac. I also experimented with various phase capacitors to achieve minimum motor vibration or cogging. The final value for this particular motor was 0.17uF resulting in the motor being dead silent with rock steady rpm.

OK it only has one speed but that's fine as the small number of 45s I have are played on my Thorens TD125.

It performs perfectly for a fraction of the cost of the other alternatives.

Attachments

Excellent effort, congratulations - great turntable - had an ADC 25 cart modded by the Garrots, mounted on an early Helius rewired tonearm - worked very well indeed.

Wow, a 500 VA transformer powering a turntable!

I suppose your amplifier features a pole transformer?

Best regards!

I suppose your amplifier features a pole transformer?

Best regards!

It performs perfectly for a fraction of the cost of the other alternatives.

Yes, but mostly because you had a free motor with a pulley. And because the absence of a motor housing or WAF do not seem to worry you much

Excellent!

I think it would be best to find some thin sheets of Sorbothane and place them under the mounting plates (both sides) and bolt them just tight enough to slightly compress the material.

Drill the base acrylic bolt holes big enough to not touch the sides of each hole.

You have enough surface area to keep it from moving around

Regards

David

I think it would be best to find some thin sheets of Sorbothane and place them under the mounting plates (both sides) and bolt them just tight enough to slightly compress the material.

Drill the base acrylic bolt holes big enough to not touch the sides of each hole.

You have enough surface area to keep it from moving around

Regards

David

Hi David.

I might have to try the sorbothane suggestion as I'm aware of its absorbing properties.

However the original Oracle mounting plate is already insulated with a layer of some sort of foam rubber and the mounting bolts have O rings for further isolation.

The level of smart engineering that went into Oracle turntables is quite amazing.

I'm OK with the motor being visible at the rear of the turntable as it is a skeleton design anyway with all its innards exposed to the world !!

Cheers

Graham

I might have to try the sorbothane suggestion as I'm aware of its absorbing properties.

However the original Oracle mounting plate is already insulated with a layer of some sort of foam rubber and the mounting bolts have O rings for further isolation.

The level of smart engineering that went into Oracle turntables is quite amazing.

I'm OK with the motor being visible at the rear of the turntable as it is a skeleton design anyway with all its innards exposed to the world !!

Cheers

Graham

WOW that's a pretty radical Delphi.

Not much of the original left other than the suspension powers by the look of it.

Well done.

Not much of the original left other than the suspension powers by the look of it.

Well done.

The only Oracle piece is the springs. I used the “Black” or heaviest versions and made sure all 3 would move in unison vertically unlike the stock Oracle that uses different wind thickness springs at their tower locations

The towers and feet I machined along with the solid billet Head schell and arm tube mounting to the air tube.

The platter is acrylic with a screw down spindle design similiar to Oracles with lead perimeter (15lbs) and uses an old Maplenoll air bearing along with the internal guts of their arm plus its motor

The air gauge and front knob adjust balance between platter and arm tube from a single pump.

Ideally 2 separate pumps wound be better, but that’s how I built it back then.

I takes less than 1psi to lift 15lbs from Maplenoll original air spindle !

Not meaning to steal the thunder but only a way to further improve on The OP,s table by separating

His new motor swap from the base with an alternative design idea

Enjoy !

Regards

David

The towers and feet I machined along with the solid billet Head schell and arm tube mounting to the air tube.

The platter is acrylic with a screw down spindle design similiar to Oracles with lead perimeter (15lbs) and uses an old Maplenoll air bearing along with the internal guts of their arm plus its motor

The air gauge and front knob adjust balance between platter and arm tube from a single pump.

Ideally 2 separate pumps wound be better, but that’s how I built it back then.

I takes less than 1psi to lift 15lbs from Maplenoll original air spindle !

Not meaning to steal the thunder but only a way to further improve on The OP,s table by separating

His new motor swap from the base with an alternative design idea

Enjoy !

Regards

David

Last edited:

Wow, a 500 VA transformer powering a turntable!

I suppose your amplifier features a pole transformer?

Best regards!

I agree 500VA is way overkill, and in another thread, we're building Speed controllers using 25VA to 80VA size. I once built another controller using 160VA, that too was way overkill. I reckon Naim used 500VA to add to the massive weight and size for user appeal, look very convincing and highly priced. 🙂

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Repowering Oracle Delphi