I am considering producing composite radiused corner caps that you can assemble with regular MDF via glued joints. It would be nice to get a gauge of how much interest is out there from people that may want a set.

In structural terms they could have foam core or be ribbed. The idea is to make them in 32" lengths so they can be cut to length. Working out the most cost effective way to do this at the moment.

Anyone interested?

In structural terms they could have foam core or be ribbed. The idea is to make them in 32" lengths so they can be cut to length. Working out the most cost effective way to do this at the moment.

Anyone interested?

Attachments

Interesting - what kind of composite? CF?

I'd be aware that you'd be competing with wood quadrant corner beading and radiusing via a router, and you've not stated how you deal with the box corners neatly - and are you aiming for domestic or professional speaker cabs?

I'd be aware that you'd be competing with wood quadrant corner beading and radiusing via a router, and you've not stated how you deal with the box corners neatly - and are you aiming for domestic or professional speaker cabs?

Currently I'm looking at using unidirectional carbon, 6ply that should be about 0.054" thick total, and possibly a woven ply in the mix.

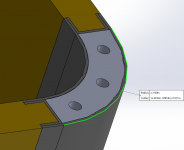

Regarding the corners to top/bottom joints, a cap gets bonded in with fastening holes. So, affix as per usual.

About routing wood, the radius's I am considering are fairly large. 2.375" in this case. I'm not familiar with the specific wood radius services you are referring to, but in that case I would just consider this method to be a different option. I personally need "corners" for differing applications and some do not include using wood, so I'm looking at a design that will have a finished appearance, not requiring further operations. Plus being as light/strong as possible.

Thanks for chiming in!

Regarding the corners to top/bottom joints, a cap gets bonded in with fastening holes. So, affix as per usual.

About routing wood, the radius's I am considering are fairly large. 2.375" in this case. I'm not familiar with the specific wood radius services you are referring to, but in that case I would just consider this method to be a different option. I personally need "corners" for differing applications and some do not include using wood, so I'm looking at a design that will have a finished appearance, not requiring further operations. Plus being as light/strong as possible.

Thanks for chiming in!

Attachments

Not interested in anything made with MDF.

To be truly effective should be a bit bigger. 100mm would be a good target.

dave

I am considering are fairly large. 2.375"

To be truly effective should be a bit bigger. 100mm would be a good target.

dave

If not mdf, perhaps bamboo, wink, wink.

On the radius size, 4" is huge, pushing the box width out a full 8"! Regarding our earlier baffle convo, I've not forgotten that bigger is better concerning diffraction. Is that a radius that people will want to implement? Perfect Radius could be your theoretical band name :-

Edit: May as well get my nomenclature well rounded-

On the radius size, 4" is huge, pushing the box width out a full 8"! Regarding our earlier baffle convo, I've not forgotten that bigger is better concerning diffraction. Is that a radius that people will want to implement? Perfect Radius could be your theoretical band name :-

Edit: May as well get my nomenclature well rounded-

Attachments

Last edited:

Bamboo, particularily, stranded/fossilized plywood varieties.

But 18mm quality ply is what most people building speakers (in my sphere). And as with any project you have to measure the actual material thickness. 18mm ply is rarely exactly 18mm an 18mm plyboo is closer to 18.7mm.

You will heve to have parts that can adapt to various thicknesses of the panels used.

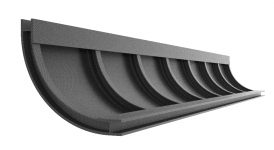

What you are trying to repace are pieces of solid like these:

dave

But 18mm quality ply is what most people building speakers (in my sphere). And as with any project you have to measure the actual material thickness. 18mm ply is rarely exactly 18mm an 18mm plyboo is closer to 18.7mm.

You will heve to have parts that can adapt to various thicknesses of the panels used.

What you are trying to repace are pieces of solid like these:

dave

Those are beauties! That radius looks a little more on par with my 2.375" iteration.

The general idea is that the inserts allow for large curves without having to physically shape wood. Handcrafted wood is the gold standard. This is more plug-n-play.

Did up a 4" radius to compare with the original and have to admit it's a good looking curve. Used "computer oak" instead of "computer mdf" for those that prefer anything non-mdf.

The general idea is that the inserts allow for large curves without having to physically shape wood. Handcrafted wood is the gold standard. This is more plug-n-play.

Did up a 4" radius to compare with the original and have to admit it's a good looking curve. Used "computer oak" instead of "computer mdf" for those that prefer anything non-mdf.

Attachments

Last edited:

That radius looks a little more on par with my 2.375" iteration

It is. Could be bigger.

dave

So, here's the rub: Once the radius gets to be much over 2" the practicality of mold construction goes down quickly. Doing some tinkering with a 4" radius insert, what I realized is that it's likely more practical/cost effective to for a flat sheet to be formed over ribs. This would eliminate the need for one large mold. This operation would lower the tooling costs but also raise the labor/construction time. Plus there is much more material involved. Probably at that size it's a much more specialty item that would be on the less affordable side. Very cool, nevertheless.

It's hard to judge what the 2.375" radius version would cost, but I'm guesstimating 20$/foot. Obviously something like this does not make sense for doing a budget build. But I can see it being handy if the profile is an important design element, and the ease of assembly is desirable. In my case, I want a good pre-formed solution for constructing "U" standard gear rack chassis', where the carbon finish is something of a feature.

It's hard to judge what the 2.375" radius version would cost, but I'm guesstimating 20$/foot. Obviously something like this does not make sense for doing a budget build. But I can see it being handy if the profile is an important design element, and the ease of assembly is desirable. In my case, I want a good pre-formed solution for constructing "U" standard gear rack chassis', where the carbon finish is something of a feature.

Attachments

Last edited:

- Home

- Design & Build

- Parts

- Radiused composite corner cabinet inserts