I have a pair of single ended output transformer from electraprint. They are slightly ugly, the laminates have rust on them, and the bells are scratched. They are not too bad, so I would like to know if it is worth doing some “improvement” on them.

1. Can I dismantle the 4 bolts holding the laminates together? I seem to remember reading performance of the air gapped transformers will be affected if they are dismantled, but I don’t remember where and why.

2. These transformers do not have a ground connection. I have come across ground connection from OPT that is basically a wire soldered on the outermost laminate. I would like to know if this is a good practice or no better than grounding the end bell.

3. I am aware that there are heat resistant paint, but I have not been able to find one that is not a spray paint. I wonder how well do regular paint stand up to tube heat, say about 2” from EL84 or 6V6.

4. Is it preferable for the bell side to face the tube heat, as opposed to the laminate side? Or it does not matter enough either way.

1. Can I dismantle the 4 bolts holding the laminates together? I seem to remember reading performance of the air gapped transformers will be affected if they are dismantled, but I don’t remember where and why.

2. These transformers do not have a ground connection. I have come across ground connection from OPT that is basically a wire soldered on the outermost laminate. I would like to know if this is a good practice or no better than grounding the end bell.

3. I am aware that there are heat resistant paint, but I have not been able to find one that is not a spray paint. I wonder how well do regular paint stand up to tube heat, say about 2” from EL84 or 6V6.

4. Is it preferable for the bell side to face the tube heat, as opposed to the laminate side? Or it does not matter enough either way.

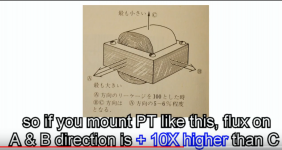

The direction the transformer faces is more about how the leaking flux lines might impact the performance of a beam power tube, than the heat. I always face the bell towards the power tube.

1. Normally you don't need to dismantle OT just to clear rust and painting. If you do you should

take some readings like voltage ratio, inductance or impedance. The I lamination are all in one lump,

it's the air-gap should be restored (clamp it down before you loosen it. You should clear the rust before

loosen the lamination to prevent rust or piece of metal get into the gap.

2. Ground the bell shield(s) to prevent shorting due to damage (to shield(s) or faults.

3. Use antirust (heat resistance and premier) for lamination.

4. power transformer mounting orientation, Horizontal vs Vertical for DIY tube amplifier - YouTube

take some readings like voltage ratio, inductance or impedance. The I lamination are all in one lump,

it's the air-gap should be restored (clamp it down before you loosen it. You should clear the rust before

loosen the lamination to prevent rust or piece of metal get into the gap.

2. Ground the bell shield(s) to prevent shorting due to damage (to shield(s) or faults.

3. Use antirust (heat resistance and premier) for lamination.

4. power transformer mounting orientation, Horizontal vs Vertical for DIY tube amplifier - YouTube

Attachments

Last edited:

Thanks guys for the info.

I am following the recommendation that the OPT and the power transformer should be oriented 90 degrees from each other. So if the power transformer has the bell facing the tubes, then the OPT would have the laminate facing the tubes.

That said, my power transformer and OPT are in the opposite sides of the chassis, with the tubes in the middle. I guess it's not that big of a deal if I make them face the same way.

As for painting, I thought it is not ideal if I spray paint everything including the screws and the insulation washer. But I guess it's not worth the effort to take them apart.

As for the rust, I tried to wipe them off as much as I could. I dare not sand them. I thought about the rust converter and the Hammerite paint, but I am wondering if I need heat resistant primer and paint here. But if the laminates are not facing the tube then they are probably fine.

Or I could buy transformer covers.

I am following the recommendation that the OPT and the power transformer should be oriented 90 degrees from each other. So if the power transformer has the bell facing the tubes, then the OPT would have the laminate facing the tubes.

That said, my power transformer and OPT are in the opposite sides of the chassis, with the tubes in the middle. I guess it's not that big of a deal if I make them face the same way.

As for painting, I thought it is not ideal if I spray paint everything including the screws and the insulation washer. But I guess it's not worth the effort to take them apart.

As for the rust, I tried to wipe them off as much as I could. I dare not sand them. I thought about the rust converter and the Hammerite paint, but I am wondering if I need heat resistant primer and paint here. But if the laminates are not facing the tube then they are probably fine.

Or I could buy transformer covers.

Interesting.It's the first time i hear about it! I already saw some local products.Not too cheap though...

Normally, I use the spray, Rust Check Rust Converter, Aerosol, 283-g Canadian Tire

but they have a version for brushing or dipping for 13$ at Canadian Tire...

Rust Check Rust Converter, 236-mL Canadian Tire

I'm sure you have a similar store where you are?

but they have a version for brushing or dipping for 13$ at Canadian Tire...

Rust Check Rust Converter, 236-mL Canadian Tire

I'm sure you have a similar store where you are?

I can find something similar here.

https://mr-mckenic.com/product/magic-rust-converter/

I only have a little bit of rust though, most of the paint on the surface is still intact, so there isn't much rust for it to convert. I am wondering if a regular primer would work better here.

https://mr-mckenic.com/product/magic-rust-converter/

I only have a little bit of rust though, most of the paint on the surface is still intact, so there isn't much rust for it to convert. I am wondering if a regular primer would work better here.

This set of instructions worked perfectly for me. I built one of his amp kit and followed his instructions to the letter.

Look on page 2 http://www.tubes4hifi.com/VTA%20ST-120%20KIT%20sample.pdf

I used a semi-gloss engine enamel from Rust oleum.

Look on page 2 http://www.tubes4hifi.com/VTA%20ST-120%20KIT%20sample.pdf

I used a semi-gloss engine enamel from Rust oleum.

Usually rust helps with Foucault's currents...Trying to file or grind the lamination can short it.

The mojo is in the rust. Leave it alone unless you need it to look shiny for sale.

Rust on the face of the lams CAN be sufficient insulation for eddy (Foucault) current, but in production it is very very thin oxidation, not fluffy/crusty rust. And not on the edges.

Coca Cola will fix rust (Phosphoric Acid), and for tiny jobs may be a lot cheaper (the leftover cleans your toilet).

Black oil-based wood stain will seal and disguise surface rust. I pulled bare steel handrail brackets from a wetland dump, dried them, and brushed with woodstain. Takes a week to dry on non-porous surface, but 7 years in a damp garage they still look swell.

Rust on the face of the lams CAN be sufficient insulation for eddy (Foucault) current, but in production it is very very thin oxidation, not fluffy/crusty rust. And not on the edges.

Coca Cola will fix rust (Phosphoric Acid), and for tiny jobs may be a lot cheaper (the leftover cleans your toilet).

Black oil-based wood stain will seal and disguise surface rust. I pulled bare steel handrail brackets from a wetland dump, dried them, and brushed with woodstain. Takes a week to dry on non-porous surface, but 7 years in a damp garage they still look swell.

How to check for lams short? Isn't there a thin insulation on both side of lams, how did it got shorted if you clear the rust correctly? It all depends, if too much rust, it will eventually burst the bobbin, there is a need then to take the necessary action.

- Home

- Amplifiers

- Tubes / Valves

- Output transformer questions