Hi Everyone,

I realize there's a lot I don't know about speaker design, especially in measurements, but I hope I can share with you another example of approaching a 2-way center channel WTW design with far-field measurements and OmniMic.

I have further realized that OmniMic is automatically blending gated and non-gated responses and that this is saving me a boatload of work. However the approach I will share should still work with REW if you know what you are doing.

My point is not to say this is the only way, but that this way is damn accurate and can save a boatload of work.

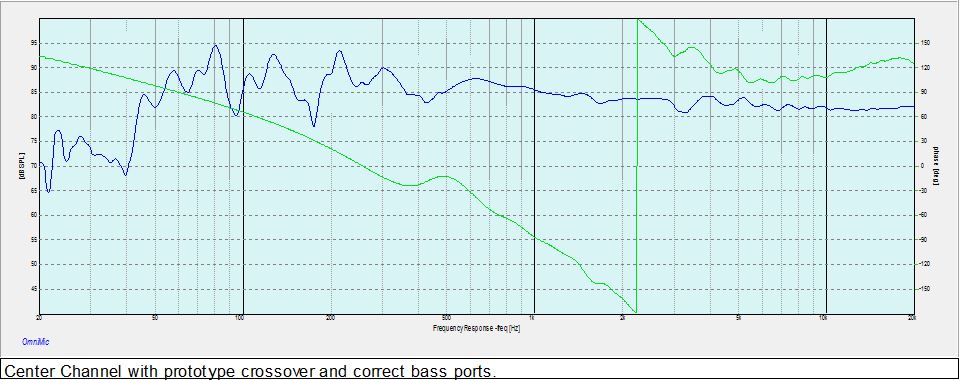

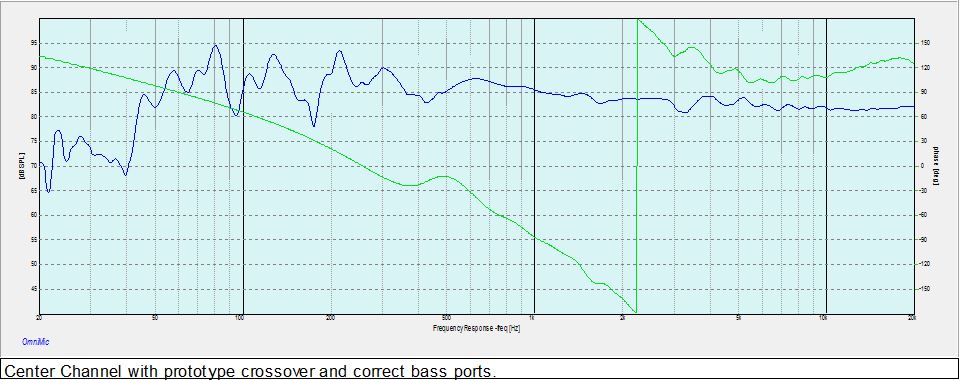

First, the proof of the pudding is in the eating, and the proof of the speaker design is in the FR, so here it is. The FR below is in place on my entertainment center, 3' away on tweeter axis, using 1/24th smoothing:

I won't share the XSim predictions cause they are just too close. The deviation from flat above is pretty much what I wanted, and also matches my main speakers. That is, I chose the bass hump and downward slope to 1 kHz. That's not an error except in choice. 😀 The bump at 90 Hz though is something I don't like, but chose to leave alone.

My process is fairly simple. I use OmniMic and measure everything at 3' away in cabinet. For the parallel woofers I had to do some cheating, which I'll discuss.

Anyway, here is the step-by-step process:

As I have elsewhere I acknowledge that this process is not suitable for speakers with crossover points in the critical bass regions where you must have near field phase and amplitude information to have any chance at designing the crossovers properly.

What I am saying however is that to design a 2 way speaker system accurately with these tools getting to done is a lot simpler than others may have realized.

If you feel there's a set of missing measurements which would help us better see the quality of the finished product, please let me know and I'll try to get it done. 🙂

As is true for 80% of what I post, I hope this is useful and informative. I know the rest is just me trolling while bored. 😀

Best,

Erik

I realize there's a lot I don't know about speaker design, especially in measurements, but I hope I can share with you another example of approaching a 2-way center channel WTW design with far-field measurements and OmniMic.

I have further realized that OmniMic is automatically blending gated and non-gated responses and that this is saving me a boatload of work. However the approach I will share should still work with REW if you know what you are doing.

My point is not to say this is the only way, but that this way is damn accurate and can save a boatload of work.

First, the proof of the pudding is in the eating, and the proof of the speaker design is in the FR, so here it is. The FR below is in place on my entertainment center, 3' away on tweeter axis, using 1/24th smoothing:

I won't share the XSim predictions cause they are just too close. The deviation from flat above is pretty much what I wanted, and also matches my main speakers. That is, I chose the bass hump and downward slope to 1 kHz. That's not an error except in choice. 😀 The bump at 90 Hz though is something I don't like, but chose to leave alone.

My process is fairly simple. I use OmniMic and measure everything at 3' away in cabinet. For the parallel woofers I had to do some cheating, which I'll discuss.

Anyway, here is the step-by-step process:

- Estimate ports with WinISD

- Route baffle, and ports.

- Attach ports and drivers

- Measure tweeter

- Measure woofers, wired in parallel.

- Measure woofer Z in parallel in cabinet.

- Hack the woofer files. Reduce FR amplitude by 6 dB and double impedance in ZMA file. This is so I can still use 2 woofers in XSim. If you want to use a virtual woofer, skip this step.

- Import driver FR and ZMA files into XSim.

- Estimate driver distances.

- Design crossover.

- Build Crossover.

- Listen. Realize that box needs to be tilted towards user's head.

- Measure.

- Done!

As I have elsewhere I acknowledge that this process is not suitable for speakers with crossover points in the critical bass regions where you must have near field phase and amplitude information to have any chance at designing the crossovers properly.

What I am saying however is that to design a 2 way speaker system accurately with these tools getting to done is a lot simpler than others may have realized.

If you feel there's a set of missing measurements which would help us better see the quality of the finished product, please let me know and I'll try to get it done. 🙂

As is true for 80% of what I post, I hope this is useful and informative. I know the rest is just me trolling while bored. 😀

Best,

Erik

I think it is a very sound plan and one I intend to try.

I have two projects to complete and the first is soon on it's way.

Both will be 2-Way. Both as simple as possible.

I'm a beginner, so need structure (and software). 😀

Plus it needs to be affordable.

There are some amazing projects on this site.

I'm not worthy of most of those accomplishments.

Your process meets my requirements.

I foolishly started with the cross-over design. I see many others jump to this also. When indeed it should be last.

One question.

Do you take the measurements with a fully assembled and damped cab?

As if its ready to go and just needs a network?

Sealed drivers and all?

I have two projects to complete and the first is soon on it's way.

Both will be 2-Way. Both as simple as possible.

I'm a beginner, so need structure (and software). 😀

Plus it needs to be affordable.

There are some amazing projects on this site.

I'm not worthy of most of those accomplishments.

Your process meets my requirements.

I foolishly started with the cross-over design. I see many others jump to this also. When indeed it should be last.

One question.

Do you take the measurements with a fully assembled and damped cab?

As if its ready to go and just needs a network?

Sealed drivers and all?

Hi BoB!

I think a lot of DIY'ers are getting into some advanced box simulations, and then taking that all the way through to the crossover design. I think it's pretty cool, but also pretty complicated.

I'm glad you find this process relatively simple, that's the whole point! 😀

I take the measurements with the fully assembled cabinet, but leave damping materials to last. I cheat and rely on really good woodworking to seal the drivers into place. The Peerless drivers for instance have a foam sealing ring. I probably should add some around the tweeter, but there's no whistling or evidence of an air leak so I don't worry too much.

Also, you may tweak a crossover about half a dozen times after you build a speaker, so it makes sense to prepare to be taking out drivers or the connector plate a few times.

There's two types of damping material. There's surface dampening like Sonic Barrier. That should reduce the movement of the panels. The fill however like Acousta-Stuff increases the cabinet size and reduces the effective Q of the cabinet. The good Dr. D'Appolito has a section on measuring the effects but I've yet to read it. Maybe I should?

One of my pet tweaks by the way is to always add Sonic Barrier around and on, the tweeters. My theory is this reduces the velocity and energy of bass frequencies before they hit the tweeter housing. It may be on par with wearing the right socks during the playoffs however. 🙂

To make this posting shorter, I usually start without any stuffing, and design the crossover based on those measurements. Then I try out the stuffing to see what measurable / audble effects would be.

Always be on the lookout for Serendipity and her sisters to appear and help you out. 🙂 You never know when a "mistake" actually does something good for your design. So don't try to quash every one until you've taken a close look. For this reason I start out with no dampening, and then add and evaluate. Also, for the crossover I did not have an "optimal" woofer coil, but built a coil out of two smaller one's with relatively high DCR. It turns out that DCR is helping me by smothing out the FR just where I needed it. Had I spent the $12 already on a new coil I would never have thought of that. At worst a mistake is a learning opportunity. At best, a real improvement. 😀

Best,

Erik

I think a lot of DIY'ers are getting into some advanced box simulations, and then taking that all the way through to the crossover design. I think it's pretty cool, but also pretty complicated.

I'm glad you find this process relatively simple, that's the whole point! 😀

I take the measurements with the fully assembled cabinet, but leave damping materials to last. I cheat and rely on really good woodworking to seal the drivers into place. The Peerless drivers for instance have a foam sealing ring. I probably should add some around the tweeter, but there's no whistling or evidence of an air leak so I don't worry too much.

Also, you may tweak a crossover about half a dozen times after you build a speaker, so it makes sense to prepare to be taking out drivers or the connector plate a few times.

There's two types of damping material. There's surface dampening like Sonic Barrier. That should reduce the movement of the panels. The fill however like Acousta-Stuff increases the cabinet size and reduces the effective Q of the cabinet. The good Dr. D'Appolito has a section on measuring the effects but I've yet to read it. Maybe I should?

One of my pet tweaks by the way is to always add Sonic Barrier around and on, the tweeters. My theory is this reduces the velocity and energy of bass frequencies before they hit the tweeter housing. It may be on par with wearing the right socks during the playoffs however. 🙂

To make this posting shorter, I usually start without any stuffing, and design the crossover based on those measurements. Then I try out the stuffing to see what measurable / audble effects would be.

Always be on the lookout for Serendipity and her sisters to appear and help you out. 🙂 You never know when a "mistake" actually does something good for your design. So don't try to quash every one until you've taken a close look. For this reason I start out with no dampening, and then add and evaluate. Also, for the crossover I did not have an "optimal" woofer coil, but built a coil out of two smaller one's with relatively high DCR. It turns out that DCR is helping me by smothing out the FR just where I needed it. Had I spent the $12 already on a new coil I would never have thought of that. At worst a mistake is a learning opportunity. At best, a real improvement. 😀

Best,

Erik

Last edited:

Erik,

Thanks for the writeup (and the plug, from both me and the folks at Dayton Audio!).

Your approach is simple, and will work pretty well for most builders. The estimated drivers distance part could hurt accuracy, depending on the types of drivers being used. In designs with sharper crossover corners or bigger driver offsets, or for people who really want to get the very closest accuracy, it might be better to do the slightly more complicated three-step measurement process to get the drivers distances exact. See http://www.diyaudio.com/forums/multi-way/287340-xsim-critique-part-2-a-7.html#post4634286

It takes a little more time, but can also provide some interesting intuition about how phase delays can affect things.

Baronski, yes, the most accuracy is if you measure with everything on the baffle and the box configured as it will be used. But, sometimes you may want to play a little first to find out just what is the best placement of everything on the baffle, or what the best baffle shape is. If you can come up with some large-enough suitable cardboard boxes and some duct tape, you can hack at it with a razor knife and drop drivers onto it to do some measurements and see what affects what and what might be a best place to start from. (Distance from box edges can have significant effect on the responses at tweeter and midrange frequencies, distance from floor will affect response at midrange to bass frequencies. At bass, look at distance from walls -- placement becomes important, and that might cosmetically affect how you want to arrange the baffle). Depends on how much of an investigation you want to turn it into.

Thanks for the writeup (and the plug, from both me and the folks at Dayton Audio!).

Your approach is simple, and will work pretty well for most builders. The estimated drivers distance part could hurt accuracy, depending on the types of drivers being used. In designs with sharper crossover corners or bigger driver offsets, or for people who really want to get the very closest accuracy, it might be better to do the slightly more complicated three-step measurement process to get the drivers distances exact. See http://www.diyaudio.com/forums/multi-way/287340-xsim-critique-part-2-a-7.html#post4634286

It takes a little more time, but can also provide some interesting intuition about how phase delays can affect things.

Baronski, yes, the most accuracy is if you measure with everything on the baffle and the box configured as it will be used. But, sometimes you may want to play a little first to find out just what is the best placement of everything on the baffle, or what the best baffle shape is. If you can come up with some large-enough suitable cardboard boxes and some duct tape, you can hack at it with a razor knife and drop drivers onto it to do some measurements and see what affects what and what might be a best place to start from. (Distance from box edges can have significant effect on the responses at tweeter and midrange frequencies, distance from floor will affect response at midrange to bass frequencies. At bass, look at distance from walls -- placement becomes important, and that might cosmetically affect how you want to arrange the baffle). Depends on how much of an investigation you want to turn it into.

Last edited:

Hi Bill!

That is an oversite in the writeup! 😀 For step 9 I meant to link to my blog post on using interferometry to get speaker distances. I never meant to say one should eyeball the distances!! Thanks for catching that blunder. The three step interferometry process is how I always do it.

I do sometimes suggest a beginner working with FRD/ZMA files from Dayton to estimate 1.2 to 1.4" if they are learning crossover design and don't actually have drivers. That is NOT what I meant to suggest in my first post however, it's too late for me to edit that.

Best,

Erik

That is an oversite in the writeup! 😀 For step 9 I meant to link to my blog post on using interferometry to get speaker distances. I never meant to say one should eyeball the distances!! Thanks for catching that blunder. The three step interferometry process is how I always do it.

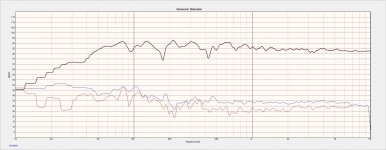

An externally hosted image should be here but it was not working when we last tested it.

I do sometimes suggest a beginner working with FRD/ZMA files from Dayton to estimate 1.2 to 1.4" if they are learning crossover design and don't actually have drivers. That is NOT what I meant to suggest in my first post however, it's too late for me to edit that.

Best,

Erik

Last edited:

- Status

- Not open for further replies.