I have been reading on vibration isolation here.

Passive and active isolation

While searching for negative stiffness isolator on YouTube found few smaller designs.

1) Rope Isolation

2) Rubber ring isolation

These would be great for isolating motor vibration. Wouldn't they ? 🙂

Regards.

Passive and active isolation

While searching for negative stiffness isolator on YouTube found few smaller designs.

1) Rope Isolation

2) Rubber ring isolation

These would be great for isolating motor vibration. Wouldn't they ? 🙂

Regards.

and how is that different from an elastomer mount that many turntables already have? Have a look at the SME turntables. Their system is relatively easy to replicate if you can build the damper.

The original post is regarding motor isolation not turntable suspension.

This is very interesting thanks for sharing those links.

I have a VPI scout and the stock motor is very loud, I have used a simple sponge from the kitchen under it with success but it settles and needs replacement after a year or so.

This is very interesting thanks for sharing those links.

I have a VPI scout and the stock motor is very loud, I have used a simple sponge from the kitchen under it with success but it settles and needs replacement after a year or so.

Same point applies. My turntable allows the motor to rotate with a spring. A little extreme as means sod all torque, but works. I thought elastomer mounting of the motors was fairly widespread?

the biggest problem with mounting a TT motor on any type of suspension is that the suspension will cause the motor to wobble which causes speed stability which can be heard as pitch variation on things like piano notes.

best way to get rid of motor noise is to use a better power supply that will run the motor with less noise. another way is to decouple the motor onto a separate heavy structure like a two tier support.

best way to get rid of motor noise is to use a better power supply that will run the motor with less noise. another way is to decouple the motor onto a separate heavy structure like a two tier support.

the biggest problem with mounting a TT motor on any type of suspension is that the suspension will cause the motor to wobble which causes speed stability which can be heard as pitch variation on things like piano notes.

Any evidence of that? Not noticed a problem in over 20 years on my TT. If you extend your argument ALL belt drive turntables have a problem (some believe this and prefer thread drive or direct drive).

Yes simple elastomer mounting works. And springs too. Very elaborate information by Mr. Volken in TD-124 thread.

Probably Rope and STO isolation works differently. In the link you can see simple rubber mounted camera (Some idler motor I presume would be approximately same weight) compared to other isolation methods. What I found interesting in those isolation from camera is objects at distance looked very very stable. That means it also isolates micro vibrations. Otherwise the objects at distance would look vibrating from camera.

Regards

Probably Rope and STO isolation works differently. In the link you can see simple rubber mounted camera (Some idler motor I presume would be approximately same weight) compared to other isolation methods. What I found interesting in those isolation from camera is objects at distance looked very very stable. That means it also isolates micro vibrations. Otherwise the objects at distance would look vibrating from camera.

Regards

You are probably right. But the STO isolation (In the link Blue and Red rings) comes with different stiffness rings so wobble can be controlled or eliminated and noise isolated. I also agree that it is better to control the problem at the source itself. But this was just to have an option. I may be wrong but the STO isolation probably is based on 'Minus K' isolation platforms. Bur rather on smaller scale.the biggest problem with mounting a TT motor on any type of suspension is that the suspension will cause the motor to wobble which causes speed stability which can be heard as pitch variation on things like piano notes.

Regards.

It's certainly worth working out a DIY test so you can try things. I think that is where the thinking needs to be. You could use the feikert test record and see if you can measure motor related pickup at a few 100Hz then try and remove it. But that is quite laborious.

Any evidence of that? Not noticed a problem in over 20 years on my TT. If you extend your argument ALL belt drive turntables have a problem (some believe this and prefer thread drive or direct drive).

A friend and I built a couple of belt drive diy tables a number of years ago and we indeed did find that too much elasticity in the motor suspension resulted in warble (flutter induced - not accurately measured by us) on piano notes. This is all anecdotal of course, but we ended up with a rigid suspension on one and an outboard motor pod with rigidly mounted motor in the other. (fishing line drive with pod) Probably largely a matter of material tuning which was beyond our resources.

TT DC Motor - AudioEnz second and fourth posts show the wonderful wacky way my motor is mounted. Barking mad from a lot of respects, but no warble problems.

I don't know how much balancing of the motor assemblies is done in production.

I don't know how much balancing of the motor assemblies is done in production.

Any evidence of that? Not noticed a problem in over 20 years on my TT. If you extend your argument ALL belt drive turntables have a problem (some believe this and prefer thread drive or direct drive).

why do you think that Rega have ditched the 'rubber band' mounting of the motor in favour of direct coupling to plinth and the likes of Pink Triangle introduced direct coupling of the motor onto the sub chassis on the Anniversary and other high end TT manufacturers use 'pods' for the motor.

yes decoupling via elastomer can work but it has to act like a solid or as near as and even then the choice of material has to be considered in case it matches another on the TT for instance lets say it ends up the same resonant frequency as the arm then its going to amplify that frequency.

now after all of that here is the real sting in the tail, if the TT sounds good to the end user then thats all that matters and the whole point is to enjoy music 🙂

Hi,

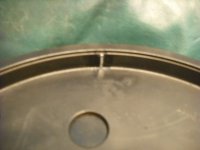

I had an old Garrard 35 turn table that I was going to discard it because a worn out motor. Then decided to see how to replace the motor and after some researched decided to use a stepper motor. To mount it used an RC helicopter fiber glass rubber mounting to hold the motor and reduce the vibration. Used a micro and easy driver to control the stepper motor speed to 33.3334 rpm. The speed it is control by reading an index marked in the platen with and infrared sensor. Then use the micro to calculate the speed of the platen. Every thing it is simple and easy to do project. It can be implemented in any turn table. It worked good and the sound it is good. Attached are some pictures of the controller, how the motor it is mounted ,the index marked in the platen and the sensor to read the index marked and the display.

I had an old Garrard 35 turn table that I was going to discard it because a worn out motor. Then decided to see how to replace the motor and after some researched decided to use a stepper motor. To mount it used an RC helicopter fiber glass rubber mounting to hold the motor and reduce the vibration. Used a micro and easy driver to control the stepper motor speed to 33.3334 rpm. The speed it is control by reading an index marked in the platen with and infrared sensor. Then use the micro to calculate the speed of the platen. Every thing it is simple and easy to do project. It can be implemented in any turn table. It worked good and the sound it is good. Attached are some pictures of the controller, how the motor it is mounted ,the index marked in the platen and the sensor to read the index marked and the display.

Attachments

These would be great for isolating motor vibration. Wouldn't they ?

The Connoisseur turntables from the 60s-70s used rubber bands to isolate the motor from the top plate.

Connoisseur BD1 Manual - 2-Speed Belt-Drive Turntable - Vinyl Engine

why do you think that Rega have ditched the 'rubber band' mounting of the motor in favour of direct coupling to plinth

cost saving? better motor sourced, dunno. Never paid Regas much attention

and the likes of Pink Triangle introduced direct coupling of the motor onto the sub chassis on the Anniversary and other high end TT manufacturers use 'pods' for the motor.

Probably because they improved the subchassis to top plate isolation, or finally built a motor controller that worked and didn't burn out after 6 months!

yes decoupling via elastomer can work but it has to act like a solid or as near as and even then the choice of material has to be considered in case it matches another on the TT for instance lets say it ends up the same resonant frequency as the arm then its going to amplify that frequency.

It's a system, no sh*t.

''Probably because they improved the subchassis to top plate isolation, or finally built a motor controller that worked and didn't burn out after 6 months!''

ROFL that pretty much sums it up. gota admit that when they are fettled they sound bloody superb.

tbh, i'm past all the faffing with TT's i just want to listen to music with the least fuss possible....

ROFL that pretty much sums it up. gota admit that when they are fettled they sound bloody superb.

tbh, i'm past all the faffing with TT's i just want to listen to music with the least fuss possible....

Secret admission: The main reason I didn't get a PT myself is that a friend had one, so I had to get something different.

Whereas I am just starting with fettling. The Xerxes just works, but I have a few, erm projects in the shed!

Whereas I am just starting with fettling. The Xerxes just works, but I have a few, erm projects in the shed!

the Xerxes is a damned fine table. i always wanted a T, Rock.

admission time, i have a PT2 and LPT also in the attic i have a Systemdek IIX and a Technics DD 150 i think it is. i have also had various other decks including an early Sondek, rega p2 and p3 my first TT was a Sansui SR212 handmedown. not even going to start on arms and carts.

admission time, i have a PT2 and LPT also in the attic i have a Systemdek IIX and a Technics DD 150 i think it is. i have also had various other decks including an early Sondek, rega p2 and p3 my first TT was a Sansui SR212 handmedown. not even going to start on arms and carts.

I like the rock too. Did very nearly buy a rock damping kit off someone here about 4 months ago but lacking funds.

These days there is so much more information about playing with TT is a lot more fun, esp if you have one that is working well so its just the second/3rd/4th you are playing with 🙂

Arms is my shortage right now.

These days there is so much more information about playing with TT is a lot more fun, esp if you have one that is working well so its just the second/3rd/4th you are playing with 🙂

Arms is my shortage right now.

dont mess with the Xerxes too much as they are like the LPT. only thing i would look out for is a drooping top plate at the arm and maybe change out the dampers for something like these

- Home

- Source & Line

- Analogue Source

- New turntable motor isolation worth exploring ?