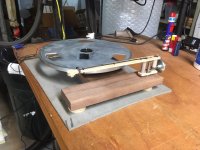

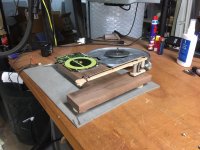

This is a early prototype of what my plinth will look like.

I need some feet thoughts. Currently I'm using some particle board discs as feet.

I'd like the feet to be 3/4" of an inch high. They need to be that high because the wiring for the motor is going to run UNDER the plinth to a terminal strip that will feed a couple of switches. One on/off, the other 33/45.

Complicating matters is my arm design which uses the 1/4-20 set screw as 1/2 of the pivot. I'd like to allow that to extend down below the plinth as well. So a foot would have to be small enough diameter to be off to the side, or large enough (2-1/2" to 3") and centered so the stud can extend through the center of the foot.

I see these giant "statement" turntables and the feet which also look like supports for arms look extremely substantial, and I'm imagining very substantial isolation systems built into them.

I've thought of using hockey pucks as I've read comments about people using them under their tables feeling they improved the sound. BUT, they are putting the pucks under existing isolation feet.

I'm not sure how critically important isolation feet are. I looked at the ones on the original SL-6 turntable (the donor of parts for this) and they rather beefy springs wrapped in some rubber, with the rubber being connected to the table. Honestly, a tape test of the table on which I have a similar SL-J33 table indicates they aren't that great, not sure how much better than nothing they are.

Any thoughts?

I need some feet thoughts. Currently I'm using some particle board discs as feet.

I'd like the feet to be 3/4" of an inch high. They need to be that high because the wiring for the motor is going to run UNDER the plinth to a terminal strip that will feed a couple of switches. One on/off, the other 33/45.

Complicating matters is my arm design which uses the 1/4-20 set screw as 1/2 of the pivot. I'd like to allow that to extend down below the plinth as well. So a foot would have to be small enough diameter to be off to the side, or large enough (2-1/2" to 3") and centered so the stud can extend through the center of the foot.

I see these giant "statement" turntables and the feet which also look like supports for arms look extremely substantial, and I'm imagining very substantial isolation systems built into them.

I've thought of using hockey pucks as I've read comments about people using them under their tables feeling they improved the sound. BUT, they are putting the pucks under existing isolation feet.

I'm not sure how critically important isolation feet are. I looked at the ones on the original SL-6 turntable (the donor of parts for this) and they rather beefy springs wrapped in some rubber, with the rubber being connected to the table. Honestly, a tape test of the table on which I have a similar SL-J33 table indicates they aren't that great, not sure how much better than nothing they are.

Any thoughts?

Attachments

I use 40mm sorbothane hemispheres, with spacers if I need more clearance. With a medium/high mass plinth these simple things work for me. I generally use 3/4/5 hemis, moving them around until I get the same measured load on each.

I think I'm going to go with Vibrapods. I'll put some small wood feet on the table that the Vibrapods can then fit over.

Hi,

You may have a look for Sylomer.

You can order Pads of different formulations and sizes.

It´s a very effective material for this application.

jauu

Calvin

You may have a look for Sylomer.

You can order Pads of different formulations and sizes.

It´s a very effective material for this application.

jauu

Calvin

There's loads here for you to choose from cheap n cheerful to affordable. I do buy some for DIY projects and they're cool.

Buy aluminum amplifier feet and get free shipping on AliExpress.com

Buy aluminum amplifier feet and get free shipping on AliExpress.com

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Need feet ideas for DIY turntable