Hello folks. I need to limit the current draw (due to power supply limitations) under extreme conditions. There are two ways to do this within the amp (I think). Reduce the overall gain to a fixed value, or add a photo-coupler circuit to the feedback loop or the gain circuit. Problem is, I have no idea how it works in the first place.

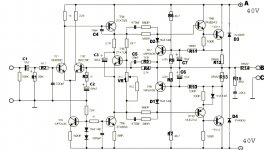

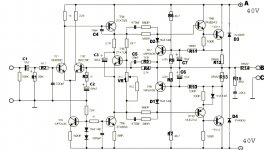

Here's the schematic:

Any comments would help greatly.

Here's the schematic:

Any comments would help greatly.

There already is current limiting built into in this circuit. That could be increased somewhat.

Limiting the gain would not protect it.

Limiting the gain would not protect it.

Thanks rayma. When I send a 20V 10kHz square wave into it, the current goes to my 3A limit, but very slowly climbs beyond that as the transistors start to roast. It was shut off before knowing how far it would go. There are also TO-220 1 Ohm 25W resistors on the rails with heatsinks.

Few audio amplifiers are designed to actually do that.

Are you using the amp in a lab for some other purpose than audio?

Are you using the amp in a lab for some other purpose than audio?

@rayma: Guitar amp. It is not expected to run at that magnitude for any significant amount of time. It happens when the low EAD strings are struck hard in the lower register. I found reducing the frequency and the magnitude of the generator significantly drops the current.

I was primarily interested in finding out if the SMPS supplies would handle the spikes. They are rated at 2.8A but maxed out with a lower value current sense resistor and the voltage adjustment was shorted which added another 3V to the 36V nominal.

I was primarily interested in finding out if the SMPS supplies would handle the spikes. They are rated at 2.8A but maxed out with a lower value current sense resistor and the voltage adjustment was shorted which added another 3V to the 36V nominal.

Nice to see a musician using the scientific approach for a change.

I wouldn't push a SMPS too far past its design limits.

I wouldn't push a SMPS too far past its design limits.

@rayma: Well the OCP circuit in those may kick in as early as 110% and as late as 200%. I just noticed in the spec sheet that voltage over/undershoot may be +/- 10%, perhaps that's why the voltage creeping rise.

The switching transistor and the planar diode are clamped to the thin, aluminum chassis/heat-sink with 1W silicone rubber boots. They were replaced with 2W thermal film.

The AC rectifier also gets very hot at 3A. They pulled the over-rated, no heat-sink bit, so a small sink will be added to those.

Additionally, the AC smoothing caps also run a little hot even at rated current. They are probably general use kind and will not last long even within rating. They are also 400V rated, since the unit may use 240V power, which will not be used. In fact, I never heard of a 240V, single phase system in the USA, unless one of the legs is considered the neutral. The caps should be replaced with 250V, low ESR units for 120VAC operation.

There may be another issue with these. Ground leakage. I have a GFCI outlet coming in to see if it will trip with the grounds disconnected from the units, and connecting the ground terminal to the outlet ground. Some of the Y caps might have to be pulled if that happens. There are quite a few of them.

Thanks much for your interest and comments.

The switching transistor and the planar diode are clamped to the thin, aluminum chassis/heat-sink with 1W silicone rubber boots. They were replaced with 2W thermal film.

The AC rectifier also gets very hot at 3A. They pulled the over-rated, no heat-sink bit, so a small sink will be added to those.

Additionally, the AC smoothing caps also run a little hot even at rated current. They are probably general use kind and will not last long even within rating. They are also 400V rated, since the unit may use 240V power, which will not be used. In fact, I never heard of a 240V, single phase system in the USA, unless one of the legs is considered the neutral. The caps should be replaced with 250V, low ESR units for 120VAC operation.

There may be another issue with these. Ground leakage. I have a GFCI outlet coming in to see if it will trip with the grounds disconnected from the units, and connecting the ground terminal to the outlet ground. Some of the Y caps might have to be pulled if that happens. There are quite a few of them.

Thanks much for your interest and comments.

Increasing R12 and R13 to 0.27R or 0.33R would reduce the current limit

I will try that. Thank you very much.

Naim amplifiers are quasi-complementary. The original product design requires they be sealed up in use and you simply allow time to pass as they warm up to operating temp and bias settles to roughly correct 35mA. Otherwise, it drifts all over the place if you open the box and room air circulates with the warm, so bias rises - maybe uncontrollably.

Yes, the thermal sensing is via the air inside the box. Sensing the output transistor or driver temperatures doesn't track correctly for low distortion and you may be courting disaster. I couldn't predict even what happens with original NAP250 model but unless you look at how the amplifier bias current can be stabilised, regardless of the PSU type, you're in for trouble.

Later models located the VBE multiplier (sense transitors) on the underside of the PCB, below the PCB and close to the aluminium case. This seemed to work faster but most were only simple rectified supplies. Linear regulators or a couple of SMPS could get a bit warm on occasion.

Yes, the thermal sensing is via the air inside the box. Sensing the output transistor or driver temperatures doesn't track correctly for low distortion and you may be courting disaster. I couldn't predict even what happens with original NAP250 model but unless you look at how the amplifier bias current can be stabilised, regardless of the PSU type, you're in for trouble.

Later models located the VBE multiplier (sense transitors) on the underside of the PCB, below the PCB and close to the aluminium case. This seemed to work faster but most were only simple rectified supplies. Linear regulators or a couple of SMPS could get a bit warm on occasion.

@ Ian

have you ever wondered why Julian had made this choice (other than by the shape of the original naim boxes) and have you ever tried to move this transistor to bring it closer to the output transistors?

have you ever wondered why Julian had made this choice (other than by the shape of the original naim boxes) and have you ever tried to move this transistor to bring it closer to the output transistors?

@Ian Finch: Aha! A fly in the ointment. My testing is on the bench. I have repeatedly checked the bias current from cold start to almost breakdown. This clone recommends 10-20mA. I tried the whole range and it seemed not to have an effect at any power level. I did twist the pot too much once and the current skyrocketed causing both SMPS to shut down.

This is going into an aluminum chassis which will also serve as the heat-sink for three SMPS supplies; the third one is for (4) 12AX7 tubes. It will have some venting but it will get fairly warm at sustained max output. One, three minute song will do this.

It might be advantageous to create a "guitar program" to send into the amp which will reflect what actually will be happening. At least I know the setup can take quite a beating, at room temperature, that is.

So much for my viewing the power amp as a black box....

Thank you for your input.

This is going into an aluminum chassis which will also serve as the heat-sink for three SMPS supplies; the third one is for (4) 12AX7 tubes. It will have some venting but it will get fairly warm at sustained max output. One, three minute song will do this.

It might be advantageous to create a "guitar program" to send into the amp which will reflect what actually will be happening. At least I know the setup can take quite a beating, at room temperature, that is.

So much for my viewing the power amp as a black box....

Thank you for your input.

I am not sure that it is a good idea to add heat sources in a box in common with this diagram because the basis of everything is the control of the internal temperature of the box which will determine the current supplied at the output.

if you add a heat source, you will "cheat" the detection transistor which will reduce the current unnecessarily even if in absolute your case being made of aluminum will also rise in temperature and participate in the artificial heating of the output transistors.

my 2 cts

if you add a heat source, you will "cheat" the detection transistor which will reduce the current unnecessarily even if in absolute your case being made of aluminum will also rise in temperature and participate in the artificial heating of the output transistors.

my 2 cts

@huggygood: Thanks for that. In the cheap amps which use a similar SS power amp, thick aluminum is used under the transistors which are bolted to the chassis proper. So the thin chassis is the fins. In square inches the total surface area is about 1,000 sq. in. and that is non-vented. The inner surface radiates heat to the interior.

If it turns out that keeping the internal ambient cool is advantageous, small aluminum heat-sinks may be added to the outside. These are actually advantageous by reason that thin alum. is flimsy and warps when heated. This reduces heat conduction between the mating surfaces which is undesirable.

The tentative plan is to use .040" copper sheet significantly larger than the transistor mating area, then on the outside directly under, a traditional but very thin aluminum piece in comparison to what we normally see in Hi-Fi amps.

I happen to have a Fender 80W solid state here just to kick around, akin to the "living room" acoustic guitar . I leave it out because I don't care if it is stolen, and sometimes I hope it would be.

I should create a "death metal" program to send into the amp simulating a song set at 100 deg. F. room ambient That is the worst case scenario. Perhaps nothing more needs to be modified beyond what already has.

If it turns out that keeping the internal ambient cool is advantageous, small aluminum heat-sinks may be added to the outside. These are actually advantageous by reason that thin alum. is flimsy and warps when heated. This reduces heat conduction between the mating surfaces which is undesirable.

The tentative plan is to use .040" copper sheet significantly larger than the transistor mating area, then on the outside directly under, a traditional but very thin aluminum piece in comparison to what we normally see in Hi-Fi amps.

I happen to have a Fender 80W solid state here just to kick around, akin to the "living room" acoustic guitar . I leave it out because I don't care if it is stolen, and sometimes I hope it would be.

I should create a "death metal" program to send into the amp simulating a song set at 100 deg. F. room ambient That is the worst case scenario. Perhaps nothing more needs to be modified beyond what already has.

Naim's products had quite low bias, so the amplifier shouldn't get much warmer than some 15°C above ambient until the power is peaking above 25W. It might not seem much power but in a musical instrument application, high power isn't the big deal it becomes with commercially produced music and audio systems, where enough power for the deep bass is the practical limit to how loud the system can go.

As huggygood already mentioned, altering or limiting the temperature 'seen' by the sensing device is a bad idea when what you need to control the bias current, is an electrical current that is analogous to the average temperature of the output stage - not a version which is subject to other influences. Otherwise, any settings won't be under control at all or only partially and the results will be about as successful as mine once, when I built a few Quasi amplifiers that either had very little current but were docile or they suddenly skyrocketed to semi-heaven when I tried to set the recommended current.

The trick that finally dawned on me, is the location of the Vbe multiplier or sense transistor and its loose thermal coupling via the air, which damps the response and makes possible a smooth bias control that doesn't react to brief signal fluctuations. Setting it may not be so simple, though. The delayed response can be frustrating to work with but if you follow the procedures often advised here for Naim gear, you shouldn't have much trouble. I've posted this link a few times now but the article is informative and gives you some insight into what works, why you shouldn't worry too much about precise settings and how simple it can be in practice, once you get the physical layout with its enclosure right. Just one thing about music - when it hits you feel no pain Scroll down to "More Naim stuff" > "bias settings in Naim amplifiers".

As huggygood already mentioned, altering or limiting the temperature 'seen' by the sensing device is a bad idea when what you need to control the bias current, is an electrical current that is analogous to the average temperature of the output stage - not a version which is subject to other influences. Otherwise, any settings won't be under control at all or only partially and the results will be about as successful as mine once, when I built a few Quasi amplifiers that either had very little current but were docile or they suddenly skyrocketed to semi-heaven when I tried to set the recommended current.

The trick that finally dawned on me, is the location of the Vbe multiplier or sense transistor and its loose thermal coupling via the air, which damps the response and makes possible a smooth bias control that doesn't react to brief signal fluctuations. Setting it may not be so simple, though. The delayed response can be frustrating to work with but if you follow the procedures often advised here for Naim gear, you shouldn't have much trouble. I've posted this link a few times now but the article is informative and gives you some insight into what works, why you shouldn't worry too much about precise settings and how simple it can be in practice, once you get the physical layout with its enclosure right. Just one thing about music - when it hits you feel no pain Scroll down to "More Naim stuff" > "bias settings in Naim amplifiers".

@Ian Finch. I had found that article after realizing my knowledge needed to increase somewhat. Then it dawned I am comparing apples to oranges. The clone, Naim NAP250 Mod Clone, is a facsimile of the original. It has a 669A mounted on the sink between the power transistors which are 2SC5200. The sellers relevant instruction as to bias and power/load are:

Output Power = RMS 80W 8R (DC+ - 40V)

Static current recommended value: voltage across the cement resistor = 1.5 MV-3MV

The current is approximately 10-20 MA.

I believe they meant "resistors". I set by voltage across the E and the C of the two transistor legs, which is across both resistors. They are 0.1R, by the way. The trim pot is also 5k, not 2.2k. But the original schematics indicate the pot to be set at 1.2k which turns out mine was.

I also saw an article online where a diyer modified a real NAP250 with a PTC near the sink to improve response time, but lost the link.

I am wondering if, for my application, the stock box unit I acquired is ok. The temp is under control with 20V input square wave at 2kz. The temp skyrockets as the frequency goes to 10kHz and trips the SMPSs exponentially sooner towards 20kHz. Everything withstands a pulse test at the highest level, but not for much more than 500mS. I have seen 150w but not for long.

I do have a question as to the 669A: Is that their temp sense?

Thanks for your comments!

Output Power = RMS 80W 8R (DC+ - 40V)

Static current recommended value: voltage across the cement resistor = 1.5 MV-3MV

The current is approximately 10-20 MA.

I believe they meant "resistors". I set by voltage across the E and the C of the two transistor legs, which is across both resistors. They are 0.1R, by the way. The trim pot is also 5k, not 2.2k. But the original schematics indicate the pot to be set at 1.2k which turns out mine was.

I also saw an article online where a diyer modified a real NAP250 with a PTC near the sink to improve response time, but lost the link.

I am wondering if, for my application, the stock box unit I acquired is ok. The temp is under control with 20V input square wave at 2kz. The temp skyrockets as the frequency goes to 10kHz and trips the SMPSs exponentially sooner towards 20kHz. Everything withstands a pulse test at the highest level, but not for much more than 500mS. I have seen 150w but not for long.

I do have a question as to the 669A: Is that their temp sense?

Thanks for your comments!

Last edited:

That's a fair question about the lone D669A transistor mounted between the power transistors. I agree that it is the Vbe multiplier transistor which senses temperature as you say and uses that sense voltage to control bias but it looks like in this kit, it's intended to be mounted on the heatsink with a thermally conductive silicone washer, like the power transistors and as you might expect for any standard Emitter-Follower or "blameless" type of amplifier. So now the amp. will surely overcompensate for temperature by slowly cutting bias to near zero. but what also often happens when the bias is cut, is the amp. becomes unstable and oscillates at some inaudible frequency, typically around the 350 kHz mark. It then may slowly get hotter and hotter until the output transistors and/or the driver transistors (D669A/B649A) burn out.

You are also using a square wave for initial testing. That's not a good idea until everything is operating satisfactorily because it will provoke instability even in a stable amp. because of the high amount of harmonic content. Only very good designs set up with optimum operating conditions, will pass such high frequency testing with flying colours. Stay with at least a simulated sinewave if you are going to test at frequencies above 1kHz. Initially, it should give plenty enough assurance it's working, to just set up the DC bias conditions and test for any excessive DC offset or spurious audio output.

The seller's product info also seems to be lifted from different sources and doesn't all apply to the kit on offer which definitely isn't the same as the original design, nor is it an LJM brand clone of any Naim model. But hey, its a very cheap clone kit. You can't expect much more than simplest possible array of circuits and cheaply available components.

You are also using a square wave for initial testing. That's not a good idea until everything is operating satisfactorily because it will provoke instability even in a stable amp. because of the high amount of harmonic content. Only very good designs set up with optimum operating conditions, will pass such high frequency testing with flying colours. Stay with at least a simulated sinewave if you are going to test at frequencies above 1kHz. Initially, it should give plenty enough assurance it's working, to just set up the DC bias conditions and test for any excessive DC offset or spurious audio output.

The seller's product info also seems to be lifted from different sources and doesn't all apply to the kit on offer which definitely isn't the same as the original design, nor is it an LJM brand clone of any Naim model. But hey, its a very cheap clone kit. You can't expect much more than simplest possible array of circuits and cheaply available components.

Last edited:

Oooh, I bolted the 669A direct! Well, this amp can really take a beating. So far with all the abuse it has never oscillated or distorted, to the best of my knowledge. The temp and waveform were monitored continuously (until one of the rails dropped out).

It should be noted, since we are in Hi-Fi land, the amp is a 6 string electric lead amp. The fundamental range is 60Hz to 1,300Hz with the magnitude diminishing the higher we go. The cathode and opamp (if involved) bypass caps all use .68-1uF for the desired roll-off; this applies to the solid state amp input as well. Bass amps are in another realm and appear to be identical to HiFi.

That said, it is virtually impossible for the guitar specified to generate either the magnitude, waveform, frequencies, and duty cycle this amp has withstood. There are 2V peak fundamental spikes going into the preamp (hence the 20V test level), but they last only for a few milliseconds. Amazingly, the SMPSs carried them with only 1,000uF output capacity, which is the limit with the model used.

Good discussion!

It should be noted, since we are in Hi-Fi land, the amp is a 6 string electric lead amp. The fundamental range is 60Hz to 1,300Hz with the magnitude diminishing the higher we go. The cathode and opamp (if involved) bypass caps all use .68-1uF for the desired roll-off; this applies to the solid state amp input as well. Bass amps are in another realm and appear to be identical to HiFi.

That said, it is virtually impossible for the guitar specified to generate either the magnitude, waveform, frequencies, and duty cycle this amp has withstood. There are 2V peak fundamental spikes going into the preamp (hence the 20V test level), but they last only for a few milliseconds. Amazingly, the SMPSs carried them with only 1,000uF output capacity, which is the limit with the model used.

Good discussion!

I have another question that, if anyone cares to pipe in, would be appreciated. Is it possible to add NFB to this amp? I know it is easy with the complimentary kind, by simply adding a high power resistor and wiring it to the circuit that controls gain. But the schematic I have (of a dedicated SS guitar amp) has the negative speaker terminal coming out of a particular place in the circuit; namely the speaker negative. In the NAP250 it's grounded.

The reason is not to limit current per se, but to simulate the response of the typical, all tube amp with the droop caused by the rectifier tube. In guitar world, the effect is the initial strike of the string produces full power--the bite, or attack--then quickly decays. It also adds a minimal amount of sustain. It looks like the R3 and/or the 22k under it is where something would be connected.

Incidentally, there is no schematic for the clone. I'll have to figure it out.

Any pointers will work. Thanks.

The reason is not to limit current per se, but to simulate the response of the typical, all tube amp with the droop caused by the rectifier tube. In guitar world, the effect is the initial strike of the string produces full power--the bite, or attack--then quickly decays. It also adds a minimal amount of sustain. It looks like the R3 and/or the 22k under it is where something would be connected.

Incidentally, there is no schematic for the clone. I'll have to figure it out.

Any pointers will work. Thanks.

Last edited:

The NAP250 schematic you attached is essentially the same as the clone. It does include some VI limiter circuits but these can simply be deleted. All you then need to do is list the TR numbers against the abbreviated transistor substitute types (e.g BC556> BC239C. 5551=2N5551>MPSA06. The Vbe muitiplier, shown as TR5 is now "669" or actually a copy of 2SD669A. Soon you'll be left with the schematic that matches the parts overlay or close enough. Just remove R6-11, D1,2, TR6,7, C6,7 and their connecting leads from the schematic, as these don't appear on your clone PCB stuffing guide.

I'm certain there are edited versions of the NAP250 or Avondale Audio's NCC200 clone schematic sans limiters, out there already because folks are scared that the limiters will hurt their precious sound. 'Funny how the original amp that uses them still sounds superb even after 50 years of further audio development.

Yes, its a "bitser" of a clone and won't show any resemblance to the original's sound quality because that lies in particular specified types of transistors but I wouldn't think you were expecting that for your purpose anyway. However, limiters would be a smart idea for guitar use, where you otherwise might need to be super careful with output peak levels.

I'm certain there are edited versions of the NAP250 or Avondale Audio's NCC200 clone schematic sans limiters, out there already because folks are scared that the limiters will hurt their precious sound. 'Funny how the original amp that uses them still sounds superb even after 50 years of further audio development.

Yes, its a "bitser" of a clone and won't show any resemblance to the original's sound quality because that lies in particular specified types of transistors but I wouldn't think you were expecting that for your purpose anyway. However, limiters would be a smart idea for guitar use, where you otherwise might need to be super careful with output peak levels.

Last edited:

- Home

- Amplifiers

- Solid State

- NAP 250 Feedback Loop/Gain Adjustment