Have nakamichi re-1 . Plays fine . Just purchased it. So haven't used it for long

Dc voltage at speaker terminals is minimal . Like 5mv dc

But after opening it I saw some black burned marks on the board

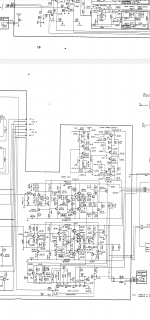

Attached are screen shots from service manual of the section where transistors are hot to touch. Very hot within a min of turning the amp on

So q317 , and q322 are hottest . Just turning the amp on will get them very hot to touch

Q320, q318 are normal

Also there is a little trace of hot running diodes

And resistors(d308, r357, r358, d309)

Are these components part of one cycle , or what's their purpose in the amp

Dc voltage at speaker terminals is minimal . Like 5mv dc

But after opening it I saw some black burned marks on the board

Attached are screen shots from service manual of the section where transistors are hot to touch. Very hot within a min of turning the amp on

So q317 , and q322 are hottest . Just turning the amp on will get them very hot to touch

Q320, q318 are normal

Also there is a little trace of hot running diodes

And resistors(d308, r357, r358, d309)

Are these components part of one cycle , or what's their purpose in the amp

Attachments

Found a thread online about simone repairing re-2

He manufactured extra heat sinks for those transistors

Attached are images of my re-1 and heat sink mod from online

Looks like these are a recurring issue on these receivers

Wondering what's the flaw in design

Also saw an eBay listing of re-1 where seller said "main power transistors have burn marks around them" receiver was sold for repairs..

How difficult will it be to find causal factor. Would higher wattage transistors resolve the issue or will spill it over to some other part of the circuitry

He manufactured extra heat sinks for those transistors

Attached are images of my re-1 and heat sink mod from online

Looks like these are a recurring issue on these receivers

Wondering what's the flaw in design

Also saw an eBay listing of re-1 where seller said "main power transistors have burn marks around them" receiver was sold for repairs..

How difficult will it be to find causal factor. Would higher wattage transistors resolve the issue or will spill it over to some other part of the circuitry

Attachments

Last edited:

Installed heat sinks from a nad amp I had laying around.

Always try to have a nad or an adcom amp around to scrap or use for parts. I believe nad and adcom engineers built their amplifiers to be used as scrap metal.

Q320 and q317 seemed to run super hot

With heatsinks u can touch and hold the heatsinks without getting burned

The bigger heatsink reduces temperature by half..

Transistor with small heat sink is about 70c

Transistor with big heatsink around 45c

Eyeballing temperatures ..handballing

So far 20min playing pretty loud. Transistors q320 and 317 are not heating up more than what they were 2 minutes after turning the nakamichi re-1 receiver on

Always try to have a nad or an adcom amp around to scrap or use for parts. I believe nad and adcom engineers built their amplifiers to be used as scrap metal.

Q320 and q317 seemed to run super hot

With heatsinks u can touch and hold the heatsinks without getting burned

The bigger heatsink reduces temperature by half..

Transistor with small heat sink is about 70c

Transistor with big heatsink around 45c

Eyeballing temperatures ..handballing

So far 20min playing pretty loud. Transistors q320 and 317 are not heating up more than what they were 2 minutes after turning the nakamichi re-1 receiver on

Attachments

Wow, that board is cooked bad. The damage is already done and the problem you have now is that dark stuff is pretty much carbon. It will conduct, causing stray current flowing everywhere around the darkened area. If you're lucky, its confined to a place where the circuitry isn't affected.

The only thing you can do is keep it from getting worse. That type of circuit board material is made from a mix of cellulose (paper) and resin, alot like a very dense form of MDF, so its sensitive to prolonged heat and moisture. You're already doing what you can to make it live longer and you can't do anymore at this point.

The only thing you can do is keep it from getting worse. That type of circuit board material is made from a mix of cellulose (paper) and resin, alot like a very dense form of MDF, so its sensitive to prolonged heat and moisture. You're already doing what you can to make it live longer and you can't do anymore at this point.

Extremely interesting.

Is it possible to test boards conductivity?

Those are pretty important transistors.

If taken out no sound condition

All components in that area had dry solder. Had to resolder or add more solder to all joints

Is it possible to test boards conductivity?

Those are pretty important transistors.

If taken out no sound condition

All components in that area had dry solder. Had to resolder or add more solder to all joints

FWIW, discolouration like that in commercial gear is pretty common on paxolin type PCB.

You can check for conductivity by simply putting your meter on a low DC volt setting and seeing if you can read any voltage on the board itself and ground. Spin the test probe into the board to get a good 'connection'. You should see nothing but stray pickup.

I doubt you will see any tbh.

You can check for conductivity by simply putting your meter on a low DC volt setting and seeing if you can read any voltage on the board itself and ground. Spin the test probe into the board to get a good 'connection'. You should see nothing but stray pickup.

I doubt you will see any tbh.

That +/-18V circuit is largely the same in the Nakamichi SR and TA series receivers as well, which are the late 80's predecessors of your unit. That circuit runs hot in all of them, as it drops a higher voltage to make regulated 18V.

From the factory, the SR series had some flimsy wings of thin Al mounted on the TO-220 devices in the 18V circuit, but they still got very hot. The solder joints do take a beating from the heat. I replaced the flimsy wings with some free-floating extruded Al sinks like yours, and it did help.

The smaller TO-92 transistors, if hot, could benefit from slip-on heat spreaders (as described here: Nakamichi TA-2A Considering a Recap | Page 2 | Audiokarma Home Audio Stereo Discussion Forums).

The 18V is used to power several of the control ICs that handle things like source and speaker switching, muting, etc., and by some opamps.

From the factory, the SR series had some flimsy wings of thin Al mounted on the TO-220 devices in the 18V circuit, but they still got very hot. The solder joints do take a beating from the heat. I replaced the flimsy wings with some free-floating extruded Al sinks like yours, and it did help.

The smaller TO-92 transistors, if hot, could benefit from slip-on heat spreaders (as described here: Nakamichi TA-2A Considering a Recap | Page 2 | Audiokarma Home Audio Stereo Discussion Forums).

The 18V is used to power several of the control ICs that handle things like source and speaker switching, muting, etc., and by some opamps.

Thanks for the info. I also have 3 ta-4a , 1 ta-3a , 1 sr-4a

Hoarding for global shortage of nakamichi in future

Should look and put some radiators in ta-4a I am using

I had a thread a while ago where I shorted bias adjustment terminals

Someone online said this results in output transistors blowing

Still have that ta-4a.. will get to it one day.

Hoarding for global shortage of nakamichi in future

Should look and put some radiators in ta-4a I am using

I had a thread a while ago where I shorted bias adjustment terminals

Someone online said this results in output transistors blowing

Still have that ta-4a.. will get to it one day.

- Home

- Amplifiers

- Solid State

- Nakamichi re-1 black burned spots on board. Transistors very hot