Hello Everyone,

I am excited to finally begin my first amplifier build. Here I hope to both chronicle the process as well as seek guidance along the way. Below, I am outlining my goals of the build as well as my experience. Then I will move on to my current progress. I would really like help with the parts list to ensure I get the right stuff. I intend to source most of the parts from mouser.com unless anyone has a better suggestion.

Goals:

-keep cost affordable (no exotic components) without sacrificing quality

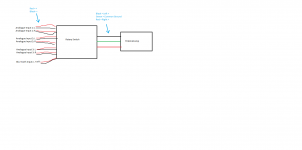

-Modular design using a mix of off the shelf components and some scratch circuit building

-Make an attractive wooden case

-Internal PSU (I do NOT want a laptop brick hanging off the back)

-Stereo output

-Volume control similar to Rod Elliott’s Better Volume Control: ESP - A Better Volume Control

-2-4 inputs: immediate inputs for Phone/Computer (3.5mm) and record player (not yet acquired).

-Room for expansion to have an all in one unit (in order of priority): phono preamp, subwoofer output, blu-tooth input.

My experience:

-Intermediate home electrical wiring: replacing outlets, adding breakers to a panel etc.

-wiring a home theater system (projector, 7.1 surround sound, etc.)

-built DC fan speed controller for computer from scratch

-built multiple desktop computers from components

-built DIY battery operated track IR clip. (simple circuit with LEDs + resistor + battery pack)

===========

On to the Build....

Stuff I already Have:

The core of the amp is one of the readily available TPA3116 stereo boards. Specifically this one:

PSU: I Currently have a 16v 4.5a laptop brick. I’m debating whether to use this with its plastic cover mounted in the chassis, remove the PSU’s plastic cover, or get a new PSU like the meanwell LRS-150-24.

Working Parts List

Here’s my working parts list organized by module. I would appreciate alternative suggestions, for components, that are either cheaper than my selections without sacrificing quality or are of superior enough real world quality to more than justify the additional cost.

PSU—Internally mounted

-I’m between using my 16v 4.5a laptop brick or the meanwell LRS-150-24. Either way, I WILL mount the PSU internally.

-AC Power Input and Switch: If I can justify the cost, a push button (like this) mounted to the front would be nice. I’m also considering an integrated power cord + fuse + switch (like this) mounted to the back. Or the budget option of a simple input (like this) along with an appropriate (cheap) switch. How beneficial is putting a fuse at the AC input? If my chassis is entirely made from wood, is it necessary to use a 3 prong grounded plug?

Volume Control

-Pot: 1 dual gang 100k ohm linear pot like this:

-Resistor: 2, 12k ohm 1% resistors like this: do I need anything bigger than 1w resistors?

Input—Cell Phone/Computer 3.5mm, Record Player, Blu-Tooth(?)

-RCA Female jacks of the appropriate color like this:

-3.5mm female jack(s) like this:

-Rotary switch like this: I’m unsure about this one. I think the circuit should use a minimum 2 pole, 2 position (for 2 analogue inputs); max 2pole/4pos (for 3 analogue inputs and 1 blu-tooth) and look something like this:

Outputs

-4 Screw type Binding Posts for stereo output. What do ya’ll recommend?

-Space for possible future expansion with an RCA sub output

I am excited to finally begin my first amplifier build. Here I hope to both chronicle the process as well as seek guidance along the way. Below, I am outlining my goals of the build as well as my experience. Then I will move on to my current progress. I would really like help with the parts list to ensure I get the right stuff. I intend to source most of the parts from mouser.com unless anyone has a better suggestion.

Goals:

-keep cost affordable (no exotic components) without sacrificing quality

-Modular design using a mix of off the shelf components and some scratch circuit building

-Make an attractive wooden case

-Internal PSU (I do NOT want a laptop brick hanging off the back)

-Stereo output

-Volume control similar to Rod Elliott’s Better Volume Control: ESP - A Better Volume Control

-2-4 inputs: immediate inputs for Phone/Computer (3.5mm) and record player (not yet acquired).

-Room for expansion to have an all in one unit (in order of priority): phono preamp, subwoofer output, blu-tooth input.

My experience:

-Intermediate home electrical wiring: replacing outlets, adding breakers to a panel etc.

-wiring a home theater system (projector, 7.1 surround sound, etc.)

-built DC fan speed controller for computer from scratch

-built multiple desktop computers from components

-built DIY battery operated track IR clip. (simple circuit with LEDs + resistor + battery pack)

===========

On to the Build....

Stuff I already Have:

The core of the amp is one of the readily available TPA3116 stereo boards. Specifically this one:

PSU: I Currently have a 16v 4.5a laptop brick. I’m debating whether to use this with its plastic cover mounted in the chassis, remove the PSU’s plastic cover, or get a new PSU like the meanwell LRS-150-24.

Working Parts List

Here’s my working parts list organized by module. I would appreciate alternative suggestions, for components, that are either cheaper than my selections without sacrificing quality or are of superior enough real world quality to more than justify the additional cost.

PSU—Internally mounted

-I’m between using my 16v 4.5a laptop brick or the meanwell LRS-150-24. Either way, I WILL mount the PSU internally.

-AC Power Input and Switch: If I can justify the cost, a push button (like this) mounted to the front would be nice. I’m also considering an integrated power cord + fuse + switch (like this) mounted to the back. Or the budget option of a simple input (like this) along with an appropriate (cheap) switch. How beneficial is putting a fuse at the AC input? If my chassis is entirely made from wood, is it necessary to use a 3 prong grounded plug?

Volume Control

-Pot: 1 dual gang 100k ohm linear pot like this:

-Resistor: 2, 12k ohm 1% resistors like this: do I need anything bigger than 1w resistors?

Input—Cell Phone/Computer 3.5mm, Record Player, Blu-Tooth(?)

-RCA Female jacks of the appropriate color like this:

-3.5mm female jack(s) like this:

-Rotary switch like this: I’m unsure about this one. I think the circuit should use a minimum 2 pole, 2 position (for 2 analogue inputs); max 2pole/4pos (for 3 analogue inputs and 1 blu-tooth) and look something like this:

Outputs

-4 Screw type Binding Posts for stereo output. What do ya’ll recommend?

-Space for possible future expansion with an RCA sub output

Attachments

Last edited:

The 'better volume control' is right in general, in praxis though you'll use in more than 95% of the time only the lower third of the rotation/attenuation range where the characteristic of the pot is very good even on cheap pots. I would think about if you should really go for the effort and the second (symmetrical) power supply for the OPs. I would do that only do that for a really powerful amplifier. Besides the effort, it's expensive compared with the rest of the amp, not really reasonable balanced.

A wood case can be very nice but radio interference might be an issue. A close-by cellphone sends packets every few minutes, even when just laying idle, you can damage your speakers (and it's annoying in any case anyway). That also goes the other way, the frequencies generated in an class-D amp can also interfere with radio/wifi/etc. reception.

Plan for vents, the heat has to go somewhere. Often an air-stream through the whole enclosure (front in - back out i.e.) with a low rpm fan is a good solution to cool all components (often forgotten: the PS).

With 16V you will only get 15W/8Ohm. If you go for 24V it's already 33W and these PS are pretty cheap to get. I was pretty sceptical at first but after I ordered one I was surprised by the good quality and got a bunch more of these 24V/150W from ebay. That was probably before the who-can-go-lowest race on these ones. If it's not too expensive I'd go for the meanwell since they are usually good quality and also have a cage, otherwise one of these chines ones.

I don't recommend your linked power-plug-combo. It's snap in and that doesn't work well with wood because the wall is too thick. And it will 'work' it's way out sooner or later because it doesn't lock well, that can be dangerous. Use instead one which can be screwed to the wall AND got enough distance between the hole and the screw. What works in metal or plastic does not always work with wood.

Use shielded cables for the signal, especally if you don't have a metal case.

A wood case can be very nice but radio interference might be an issue. A close-by cellphone sends packets every few minutes, even when just laying idle, you can damage your speakers (and it's annoying in any case anyway). That also goes the other way, the frequencies generated in an class-D amp can also interfere with radio/wifi/etc. reception.

Plan for vents, the heat has to go somewhere. Often an air-stream through the whole enclosure (front in - back out i.e.) with a low rpm fan is a good solution to cool all components (often forgotten: the PS).

With 16V you will only get 15W/8Ohm. If you go for 24V it's already 33W and these PS are pretty cheap to get. I was pretty sceptical at first but after I ordered one I was surprised by the good quality and got a bunch more of these 24V/150W from ebay. That was probably before the who-can-go-lowest race on these ones. If it's not too expensive I'd go for the meanwell since they are usually good quality and also have a cage, otherwise one of these chines ones.

I don't recommend your linked power-plug-combo. It's snap in and that doesn't work well with wood because the wall is too thick. And it will 'work' it's way out sooner or later because it doesn't lock well, that can be dangerous. Use instead one which can be screwed to the wall AND got enough distance between the hole and the screw. What works in metal or plastic does not always work with wood.

Use shielded cables for the signal, especally if you don't have a metal case.

The 'better volume control' is right in general, in praxis though you'll use in more than 95% of the time only the lower third of the rotation/attenuation range where the characteristic of the pot is very good even on cheap pots. I would think about if you should really go for the effort and the second (symmetrical) power supply for the OPs. I would do that only do that for a really powerful amplifier. Besides the effort, it's expensive compared with the rest of the amp, not really reasonable balanced.

So you're saying that just a straight pot would be fine? Would I still want a 100k ohm and 2 gang? Just in case i wasn't clear, I have no desire to build the complex balance control he outlines in the article. I was planning to build the simple pot + resistor circuit.

A wood case can be very nice but radio interference might be an issue. A close-by cellphone sends packets every few minutes, even when just laying idle, you can damage your speakers (and it's annoying in any case anyway). That also goes the other way, the frequencies generated in an class-D amp can also interfere with radio/wifi/etc. reception.

So, would I be better off using an off the shelf metal project box and attach the wood to that?

Plan for vents, the heat has to go somewhere. Often an air-stream through the whole enclosure (front in - back out i.e.) with a low rpm fan is a good solution to cool all components (often forgotten: the PS).

Thanks for the reminder, I have been kicking around the idea of whether or not to use a fan. i was thinking a 40 or 60mm computer case fan that runs quiet (~20dbs). Do you have any specific recommendations?

I don't recommend your linked power-plug-combo. It's snap in and that doesn't work well with wood because the wall is too thick. And it will 'work' it's way out sooner or later because it doesn't lock well, that can be dangerous. Use instead one which can be screwed to the wall AND got enough distance between the hole and the screw. What works in metal or plastic does not always work with wood.

Use shielded cables for the signal, especally if you don't have a metal case.

Good to know

So you're saying that just a straight pot would be fine? Would I still want a 100k ohm and 2 gang? Just in case i wasn't clear, I have no desire to build the complex balance control he outlines in the article. I was planning to build the simple pot + resistor circuit.

You can ofcourse use the pot + resistor circuit but for low power amps esp. the Pt. 2 one is simply overkill. But even the pot+resistor isn't really needed. It makes absolutely no difference if the pot is not 'clean' log, unless you need to use a dB-scale to adjust the level absolutely exactly. You'd also need a VU-meter (or oszi, not a multimeter) and adjust the scale precisely to gain any real advantage out of it. It is much easier and faster to adjust the level correctly by getting a VU-Meter and measure the level instead of trust the input level and the scale. I mean, your input sources are most likely not exactly adjusted to a precise output level and I honestly doubt you'd need a precise adjusted gain/amplification - don't forget, even different tracks got a lot different gain, you can't rely on them having all the same level after all. That better volume control MIGHT sometimes (very rarely) be useful for lab measurements but for that a class-D amp isn't suited at all anyway because of the impedance dependency on the upper end (the impedance interacts with the output filter).

Besides that, I prefer 50k pots for most uses. But that depends how you use them and what pre-/amp you use etc.

So, would I be better off using an off the shelf metal project box and attach the wood to that?

You can do it that way but there's nothing wrong in doing the wood case and mount tin sheets on the inside. You just have to make sure they are conneced to the GND. What's preferable depends on if you are better with woodworking or metal sheet working. There are other methods to build a shielded case too.

Thanks for the reminder, I have been kicking around the idea of whether or not to use a fan. i was thinking a 40 or 60mm computer case fan that runs quiet (~20dbs). Do you have any specific recommendations?

I would use a lot quieter fan, in doubt/need of more airflow use maybe two and adjust the airflow and noise/rpm through the voltage. That way a temperature regulated fan will probably not work properly anymore though. The last fan I bought was a small 40mm Cooltek Silent Fan 4010, which only makes 12,8 dBA, really quiet. There are a lot other good fans in multiple sizes, airflow specs etc and they don't have to be expensive. You should mount them with rubber or foam pads though to avoid vibration excitation of the case.

You can ofcourse use the pot + resistor circuit but for low power amps esp. the Pt. 2 one is simply overkill. But even the pot+resistor isn't really needed. It makes absolutely no difference if the pot is not 'clean' log, unless you need to use a dB-scale to adjust the level absolutely exactly. You'd also need a VU-meter (or oszi, not a multimeter) and adjust the scale precisely to gain any real advantage out of it. It is much easier and faster to adjust the level correctly by getting a VU-Meter and measure the level instead of trust the input level and the scale. I mean, your input sources are most likely not exactly adjusted to a precise output level and I honestly doubt you'd need a precise adjusted gain/amplification - don't forget, even different tracks got a lot different gain, you can't rely on them having all the same level after all. That better volume control MIGHT sometimes (very rarely) be useful for lab measurements but for that a class-D amp isn't suited at all anyway because of the impedance dependency on the upper end (the impedance interacts with the output filter).

Besides that, I prefer 50k pots for most uses. But that depends how you use them and what pre-/amp you use etc.

I don't plan to use a pre-amp except for a phono once I get a turn table. Also all volume adjustment will be by ear--no meters or anything. As a professional classical musician, I'm very protective of my hearing. I even wear ear plugs most of the time when I'm on stage with the symphony. So, most listening will be at moderate levels.

Could you explain the pros/cons of 50k vs 100k pot for my application?

You can do it that way but there's nothing wrong in doing the wood case and mount tin sheets on the inside. You just have to make sure they are conneced to the GND. What's preferable depends on if you are better with woodworking or metal sheet working. There are other methods to build a shielded case too.

I'm very good with woodworking, but have zero experience with metal working. What solution would you suggest for shielding the amp that balances cost, simplicity, and minimal metal working?

I don't plan to use a pre-amp except for a phono once I get a turn table. Also all volume adjustment will be by ear--no meters or anything. As a professional classical musician, I'm very protective of my hearing. I even wear ear plugs most of the time when I'm on stage with the symphony. So, most listening will be at moderate levels.

If no preamp equalizes the level of the sources they'll never have the same exact level. You said you adjust it by ear, not by scale or exact potentiometer angle of rotation. Plus, you can easily adjust the gain of the amp to use the pot where it works best for you anyway, the datasheet explains how you can change the gain. That means, there is not much of an argument left for the 'Better Volume Control' then.

Could you explain the pros/cons of 50k vs 100k pot for my application?

I'll keep it short. Higher resistances produce more noise. This page explains resistor noise (for the purpose of an explanation you could skip the first paragraph which shows the calculation). From that point of view, lower resistances are desirable. On the other hand you want a low load on your source, that means, you want a higher input impedance, that would mean, higher values are better. In my opinion with just a pot and the input capacitor on the source side, a 50k log pot is often the best option. There are ofcourse also other cases and reasons why other values could be preferable.

BTW: With the 'Better Volume Control' you need a higher value potentiometer because of the following parallel resistor. So you are trading potentially noise for precision. If that's a trade off depends on the situation.

I'm very good with woodworking, but have zero experience with metal working. What solution would you suggest for shielding the amp that balances cost, simplicity, and minimal metal working?

It's probably easier then to build the shielding first and then the wood part. What technique works best for that depends strongly on the dimensions and material though. Just keep in mind, you don't have to work to perfect wood/metal contact all around, just one fiting surface for mounting the amp and cage is enough, i.e. the bottom.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Class D

- My first Amplifier Build (TPA3116)