Greetings all,

I was here for long time as a reader but recently I have purchased Gryphon audio system and I would like to know more about them.

System is composed of Preamp and a power amplifier.

1- Gryphon LE limited edition 91 of 100

2- Gryphon DM 100 limited edition.

I did some research but. I couldn’t find detailed reviews. Since these seem to be old models. Please if you know any information about the models like when was manufactured or specifics design criteria it would be great. By the way the system sounds fabulous in my room.

Thanks 🙏

Ahmed

I was here for long time as a reader but recently I have purchased Gryphon audio system and I would like to know more about them.

System is composed of Preamp and a power amplifier.

1- Gryphon LE limited edition 91 of 100

2- Gryphon DM 100 limited edition.

I did some research but. I couldn’t find detailed reviews. Since these seem to be old models. Please if you know any information about the models like when was manufactured or specifics design criteria it would be great. By the way the system sounds fabulous in my room.

Thanks 🙏

Ahmed

I found this:

https://hometheaterreview.com/gryphon-dm100-dual-mono-amplifier-reviewed/

and this:

https://hometheaterreview.com/gryphon-limited-edition-preamp-reviewed/

They seem to be from 91.

More fun here:

https://www.hifinext.com/what-hi-fi-amplifiers-looked-like-30-years-ago-and-how-they-look-now/#q1

https://hometheaterreview.com/gryphon-dm100-dual-mono-amplifier-reviewed/

and this:

https://hometheaterreview.com/gryphon-limited-edition-preamp-reviewed/

They seem to be from 91.

More fun here:

https://www.hifinext.com/what-hi-fi-amplifiers-looked-like-30-years-ago-and-how-they-look-now/#q1

Thanks for sharing,

Information regarding the DM 100 is interesting. But for the LE preamplifier it does not match the model I have.

Information regarding the DM 100 is interesting. But for the LE preamplifier it does not match the model I have.

Greetings all,

I would like to ask you for a favor, I am planning to get these amp and power amp recapped and I believe I can do it but a guidance from you would be appreciated.

Current status of both are working fine and temperatures are stable in the power amp with 100% class A.

I have experience in recapping Studer tape recorders and I have done few DIY projects. However this is a beast and I don’t want to miss out with it. However I am in Saudi Arabia and there are no good dealers that can do the job for me.

Also I can pay for guides from your experience or donate to the website and attach the evidence.

I have seen some pictures online of the machine and we can plan for recap.

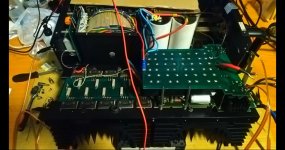

These are the photos of my gear.

If I receive a commitment from you I can start a new thread and start.

Regards

Ahmed

I would like to ask you for a favor, I am planning to get these amp and power amp recapped and I believe I can do it but a guidance from you would be appreciated.

Current status of both are working fine and temperatures are stable in the power amp with 100% class A.

I have experience in recapping Studer tape recorders and I have done few DIY projects. However this is a beast and I don’t want to miss out with it. However I am in Saudi Arabia and there are no good dealers that can do the job for me.

Also I can pay for guides from your experience or donate to the website and attach the evidence.

I have seen some pictures online of the machine and we can plan for recap.

These are the photos of my gear.

If I receive a commitment from you I can start a new thread and start.

Regards

Ahmed

Attachments

Hi Ramadhan96,

There are some capacitors known to be bad, some that ran hot and similar things. Aside from this, it is highly recommended that you do not just "recap" equipment. For example, some A-77 capacitors are almost always bad, yet in older equipment in different brands, the capacitors are fine. I was authorized warranty for Revox and worked on Studer along with many top brands.

So if the internal temperatures of your equipment were high (like many earlier Krell amplifiers), you may need to replace filter capacitors. Normal amplifier filter capacitors may be perfectly fine, you are further ahead not touching them. I receive equipment for repair that once worked fine, and after a recap they don't and I have to clean up the mess that was made. Most often I note the customer was charged for unnecessary work, and things that need to be done were not. Wasted money.

I'm guessing that if a good shop will not do the work for you, they have a good reason. Your pictures are so dark I can't make out what you have.

There are some capacitors known to be bad, some that ran hot and similar things. Aside from this, it is highly recommended that you do not just "recap" equipment. For example, some A-77 capacitors are almost always bad, yet in older equipment in different brands, the capacitors are fine. I was authorized warranty for Revox and worked on Studer along with many top brands.

So if the internal temperatures of your equipment were high (like many earlier Krell amplifiers), you may need to replace filter capacitors. Normal amplifier filter capacitors may be perfectly fine, you are further ahead not touching them. I receive equipment for repair that once worked fine, and after a recap they don't and I have to clean up the mess that was made. Most often I note the customer was charged for unnecessary work, and things that need to be done were not. Wasted money.

I'm guessing that if a good shop will not do the work for you, they have a good reason. Your pictures are so dark I can't make out what you have.

This is a fully Class A amplifier that runs very very hot and is 30+ years old. I am no expert but the question on recapping seems entirely reasonable.

But this is a "luxury" expensive audio component and someone smart should do the job.

And hey- post some pics of the inside! Top panel removed and bottem panel removed; caps may be easily accessible for all we know.

But this is a "luxury" expensive audio component and someone smart should do the job.

And hey- post some pics of the inside! Top panel removed and bottem panel removed; caps may be easily accessible for all we know.

Last edited:

hello @anatech,

Appreciate your reply. What I have are LE preamp and Dm100 power amplifier. Here are other pictures.

All caps used high quality Rifas and few ROE.

Mains filter caps Rifas PEH169 long life caps and for the axial they are PRG 124 also very long life caps.

Caps in the power amp.

4 x 47000uf 63v PEH169

8 x 220uf 100v PEG124

4 x 47uf 100v PEG124

24x 1800uf 100v Sprague 88D special design see attached Datasheet

These what I counted from the pictures in the internet and I can see the same in my unit .

For the preamp

There are 150x 470uf 40v ROE backlite EK series I think, and these are known to fail but in my unit they did not seems too and there are no cracks and the power supply is constant.

For the preamp section

8 x 1000uf 25v PEG124

4 x 220uf 50v PEG124

These are a reference picture from the internet. I got a permission from the YouTube channel for clarification.

Appreciate your reply. What I have are LE preamp and Dm100 power amplifier. Here are other pictures.

All caps used high quality Rifas and few ROE.

Mains filter caps Rifas PEH169 long life caps and for the axial they are PRG 124 also very long life caps.

Caps in the power amp.

4 x 47000uf 63v PEH169

8 x 220uf 100v PEG124

4 x 47uf 100v PEG124

24x 1800uf 100v Sprague 88D special design see attached Datasheet

These what I counted from the pictures in the internet and I can see the same in my unit .

For the preamp

There are 150x 470uf 40v ROE backlite EK series I think, and these are known to fail but in my unit they did not seems too and there are no cracks and the power supply is constant.

For the preamp section

8 x 1000uf 25v PEG124

4 x 220uf 50v PEG124

These are a reference picture from the internet. I got a permission from the YouTube channel for clarification.

Attachments

-

IMG_3111.jpeg221 KB · Views: 126

IMG_3111.jpeg221 KB · Views: 126 -

IMG_3112.jpeg186.8 KB · Views: 118

IMG_3112.jpeg186.8 KB · Views: 118 -

IMG_3113.jpeg230.7 KB · Views: 117

IMG_3113.jpeg230.7 KB · Views: 117 -

IMG_3114.jpeg121.9 KB · Views: 112

IMG_3114.jpeg121.9 KB · Views: 112 -

IMG_3115.jpeg219 KB · Views: 117

IMG_3115.jpeg219 KB · Views: 117 -

IMG_3116.jpeg228.1 KB · Views: 112

IMG_3116.jpeg228.1 KB · Views: 112 -

IMG_3117.jpeg173.1 KB · Views: 107

IMG_3117.jpeg173.1 KB · Views: 107 -

IMG_3118.jpeg214.7 KB · Views: 108

IMG_3118.jpeg214.7 KB · Views: 108 -

IMG_3119.jpeg223.6 KB · Views: 107

IMG_3119.jpeg223.6 KB · Views: 107 -

IMG_3120.jpeg224.1 KB · Views: 107

IMG_3120.jpeg224.1 KB · Views: 107 -

IMG_3121.jpeg234.8 KB · Views: 103

IMG_3121.jpeg234.8 KB · Views: 103 -

IMG_3102.jpeg555.7 KB · Views: 106

IMG_3102.jpeg555.7 KB · Views: 106 -

IMG_3099.jpeg884 KB · Views: 123

IMG_3099.jpeg884 KB · Views: 123 -

Sprague 88d.pdf871.1 KB · Views: 47

Ah, you already took it apart - good luck.

I owned Gryphon DM100 and XT at the time, nearly 35 years ago.

First repair of the DM100 was in 2012 and it was not a cap. Someone

smart would probably agree not to exchange caps at random.

I owned Gryphon DM100 and XT at the time, nearly 35 years ago.

First repair of the DM100 was in 2012 and it was not a cap. Someone

smart would probably agree not to exchange caps at random.

appreciate your reply all I will consider your suggestions and I will take it seriously so please.

I did not do that it’s from the internet. I don’t want to do it but if you say so I will. 😅 I understand the requirements that is why I am asking your experience. Unfortunately we don’t have any dealers or repair shops in The kingdom. Nearest please is 2000km away and shipping this will put it at risk.

I did not do that it’s from the internet. I don’t want to do it but if you say so I will. 😅 I understand the requirements that is why I am asking your experience. Unfortunately we don’t have any dealers or repair shops in The kingdom. Nearest please is 2000km away and shipping this will put it at risk.

In post 4 I read "both are working fine", so for me no reason for a change.

Gryphon chose parts very carefully. You will have a problem to source spares

of similar quality.

Gryphon chose parts very carefully. You will have a problem to source spares

of similar quality.

I agree with you there are no PEG nor PEH in the reputable market such as mouser with the same values. Also for the ROE no availability with the same ESR.

I have been using this system for 8 months and all going well so far.

I have been using this system for 8 months and all going well so far.

Yes, some parts pretty much have to be replaced with the same thing, or at least case style. I have seen shorted Rifa filter caps, but it really depends on how they have been used.

Keep the system well ventilated and cool if you can.

Now for service, a very competent service shop or person is sometimes better than factory service if they know exactly what they are doing. The factory has the advantage of being very familiar with the product and having proper replacement parts. It's more difficult for outside service, but I have seen external service do a much better job depending on the tech. I wish we could always say factory service was always better.

Keep the system well ventilated and cool if you can.

Now for service, a very competent service shop or person is sometimes better than factory service if they know exactly what they are doing. The factory has the advantage of being very familiar with the product and having proper replacement parts. It's more difficult for outside service, but I have seen external service do a much better job depending on the tech. I wish we could always say factory service was always better.

Revox / Studer is a peculiar example. As I'm sure you know, their general build and design is pretty much second-to-none, yet they specified two of the worst caps ever fitted to audio (or any other electronics for that matter): Frako electrolytics (they go low DCR...as well as leak green gunk that's hard to remove) and Rifa X2 caps (they go bang and smoke). Studer is an extreme example. If you take some of the Japanese caps such as Nippon Chemicon, I recently re-capped a 1978 Hitachi amp (I have a Hakko FR301 and suggest that the OP goes nowhere near his amp without one) and found all the caps to be within spec... I am not a blanket re-capper and only did it as the fusible Rs needed changing and I had spare caps in stock. In truth, I could reuse the Nippon caps. So, to back up what you're saying: change out known rogues such as Frako or Rifa on sight, but if they are of known quality, then the chances are that they are good. I would be more concerned about checking offsets and bias settings in an amp of this age. Trimmers and resistors can drift over time. If the various test point voltages are within spec, I would leave the amp alone and enjoy it.Hi Ramadhan96,

There are some capacitors known to be bad, some that ran hot and similar things. Aside from this, it is highly recommended that you do not just "recap" equipment. For example, some A-77 capacitors are almost always bad, yet in older equipment in different brands, the capacitors are fine. I was authorized warranty for Revox and worked on Studer along with many top brands.

So if the internal temperatures of your equipment were high (like many earlier Krell amplifiers), you may need to replace filter capacitors. Normal amplifier filter capacitors may be perfectly fine, you are further ahead not touching them. I receive equipment for repair that once worked fine, and after a recap they don't and I have to clean up the mess that was made. Most often I note the customer was charged for unnecessary work, and things that need to be done were not. Wasted money.

I'm guessing that if a good shop will not do the work for you, they have a good reason. Your pictures are so dark I can't make out what you have.

Studer / Revox was certainly a weird mix of design. They generally designed things extremely well. But you'll find some of the most stupid mistakes as well.

B242, high voltage between two adjacent pads, it arcs and tracks, then burns. B251, thin traces, tiny pads and some parts that run way too hot. B77, the record LEDs are in series with record bias relays. Result, open LEDs sometimes. On and on. Even the large 24 track machines have odd design oversights. It always mystified me.

The A77 was the poster child for extremely horrible capacitors used by Studer / Revox. Did someone in procurement get paid off? lol!

B242, high voltage between two adjacent pads, it arcs and tracks, then burns. B251, thin traces, tiny pads and some parts that run way too hot. B77, the record LEDs are in series with record bias relays. Result, open LEDs sometimes. On and on. Even the large 24 track machines have odd design oversights. It always mystified me.

The A77 was the poster child for extremely horrible capacitors used by Studer / Revox. Did someone in procurement get paid off? lol!

- Home

- Amplifiers

- Solid State

- More information about Gryphon audio equipment