Hello,

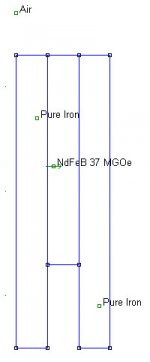

I want to experiment whith planar and ribbon and want to do this kind of magnetic circuit :

(The schematic is not in scale.)

I wanted to know which metal to use for the best field in the airgap, pure iron, stainless steel, silicium steel, and where to find it...

Thanks a lot

Hugues

I want to experiment whith planar and ribbon and want to do this kind of magnetic circuit :

(The schematic is not in scale.)

I wanted to know which metal to use for the best field in the airgap, pure iron, stainless steel, silicium steel, and where to find it...

Thanks a lot

Hugues

Attachments

Hello,

Any regular mild steel will work well... it has low cost... and is relatively easy to cut and form.

Because your magnetic field is constant (not moving), the "magnetic" properties of the steel are not important.

😀

Any regular mild steel will work well... it has low cost... and is relatively easy to cut and form.

Because your magnetic field is constant (not moving), the "magnetic" properties of the steel are not important.

😀

Yes, some metals can handle more "flow" In the case of a gapped magnetic circuit, the gap will limit or control the "flow".

Magnetic circuits can be compared to resistor circuits... that is often how they are taught. Consider a 1 Ohm resistor as the IRON; and a 1000 Ohm as the AIR GAP. Place these in series... you can see that the Iron makes very little difference.

Silicon steels and other are chosen because of their properties when the magnetic field is changing... like a transformer.

😀

Magnetic circuits can be compared to resistor circuits... that is often how they are taught. Consider a 1 Ohm resistor as the IRON; and a 1000 Ohm as the AIR GAP. Place these in series... you can see that the Iron makes very little difference.

Silicon steels and other are chosen because of their properties when the magnetic field is changing... like a transformer.

😀

Search the forum for “low carbon” for a bit of insight. I think FEMM has some of the common ones in its materials library. Be aware though that the availability and machine-ability of the metal can be a problem with the low-carbon types.

-Casey Walsh

-Casey Walsh

Actually, pure iron is rather hard to find and poor to work with... What will work for you is "MILD STEEL". Steel is essentially Iron with a small amount of carbon.

And yes, the thickness will matter. The steel should be at least as thick as your gap is long (not the thickness of the gap). The shape is extremely important though. These days the shape of magnetic components is designed with software... it is rather complicated, but there are people on this site which can do magnetic modeling. It is also possible just to sketch something out and get a decent result.

Show us a sketch of your plan.

😀

And yes, the thickness will matter. The steel should be at least as thick as your gap is long (not the thickness of the gap). The shape is extremely important though. These days the shape of magnetic components is designed with software... it is rather complicated, but there are people on this site which can do magnetic modeling. It is also possible just to sketch something out and get a decent result.

Show us a sketch of your plan.

😀

There is no pure iron on the earth.In fact , the most 'pure' iron is extremely expensive and very hard to manufacture, only maybe few grams exist all over the world.

As far as i know , standard carbon steel saturates faster than special transformer steel.

I don't know about stainless steel, maybe it is better ?

As far as i know , standard carbon steel saturates faster than special transformer steel.

I don't know about stainless steel, maybe it is better ?

And yes, the thickness will matter. The steel should be at least as thick as your gap is long (not the thickness of the gap). The shape is extremely important though. These days the shape of magnetic components is designed with software... it is rather complicated, but there are people on this site which can do magnetic modeling. It is also possible just to sketch something out and get a decent result.

Show us a sketch of your plan.

The problem is that I have to do something like this (picture bolow, in scale, one dot=1mm) and I have not space on both side to put so a lot of iron.... The best I can do is 1,5mm of thickness for the iron.

Do you think it wil work properly???

Attachments

No, I do not think it will work well.

Try to imagine a shape like a "C". Cut the "C" in the back and place your magnet there.

Why must your design be so narrow?

Try to imagine a shape like a "C". Cut the "C" in the back and place your magnet there.

Why must your design be so narrow?

Try to imagine a shape like a "C". Cut the "C" in the back and place your magnet there.

Sorry but I don't understand. Can you make a sketch if possible?

Why must your design be so narrow?

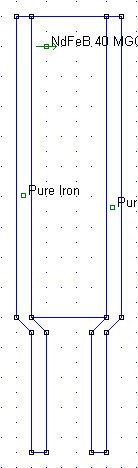

Because I have to put some same other magnetic system just near this one, something like this...

Attachments

Stainless steel is not a useable material. Just model with mild steel and don't worry about pure iron or permendur which is probably unrealistic to source and machine.

I'm not sure how that circuit is supposed to function from the diagram, but since you're using FEMM why don't you evaluate the circuit and you can see what you're circuit is doing:

I'm not sure how that circuit is supposed to function from the diagram, but since you're using FEMM why don't you evaluate the circuit and you can see what you're circuit is doing:

An externally hosted image should be here but it was not working when we last tested it.

Well maybe  vikash can model the magnetics for you.

vikash can model the magnetics for you.  It looks like he has the software!

It looks like he has the software!

You will have to comprimise your shape. The flux goes where it wants to... you can only help guide it.

vikash can model the magnetics for you.

vikash can model the magnetics for you.  It looks like he has the software!

It looks like he has the software!You will have to comprimise your shape. The flux goes where it wants to... you can only help guide it.

I've done some simulation with supermalloy and it seems to be the best material for my application. Do you think it's possible to find some???

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Magnetic circuit