I have several CD players from the late 1980s (mostly Philips). These use either the std. CDM-4 "toy" motor or the better Hall-effect motor.

These CDPs have mostly been in storage all these years. I do realize that oil degrades regardless of use/non-use.

Given low to normal use (mostly low), how often should the main (turbtable) disc-spin motor be lubricated?

What are signs to look for that the motor needs lube?

What is the best oil/lube to use?

Thanks.

These CDPs have mostly been in storage all these years. I do realize that oil degrades regardless of use/non-use.

Given low to normal use (mostly low), how often should the main (turbtable) disc-spin motor be lubricated?

What are signs to look for that the motor needs lube?

What is the best oil/lube to use?

Thanks.

Hello,

While I don't lube a small motor like this as if you get oil into the bushing/brushes/contacts you can cause a failure. Don't ask how I know this.

What I do do is take a can of silicon spray lube, spray a little into the cap to collect some liquid and then use a Q tip dipped lightly in it to lube the rails and moving parts. Don't want to use to much or have drips anywhere.

This has worked well for me as I have some pretty old players that still work just fine.

FWIW Greg

While I don't lube a small motor like this as if you get oil into the bushing/brushes/contacts you can cause a failure. Don't ask how I know this.

What I do do is take a can of silicon spray lube, spray a little into the cap to collect some liquid and then use a Q tip dipped lightly in it to lube the rails and moving parts. Don't want to use to much or have drips anywhere.

This has worked well for me as I have some pretty old players that still work just fine.

FWIW Greg

I use a syringe with needle and place a drop of bearing-oil as close to the shaft as possible. Did this shortly with two toy motors. After one day, thes small drop was

soaked up by the bearing.

Just out of curiosity, remembering C3PO in the first Star Wars:

Why can it do harm to "whash" a toy-motor with oil? It is non conducting,

and probably not agressive…?

Is it that residue from the contacts clogs everything…?

soaked up by the bearing.

Just out of curiosity, remembering C3PO in the first Star Wars:

Why can it do harm to "whash" a toy-motor with oil? It is non conducting,

and probably not agressive…?

Is it that residue from the contacts clogs everything…?

Last edited:

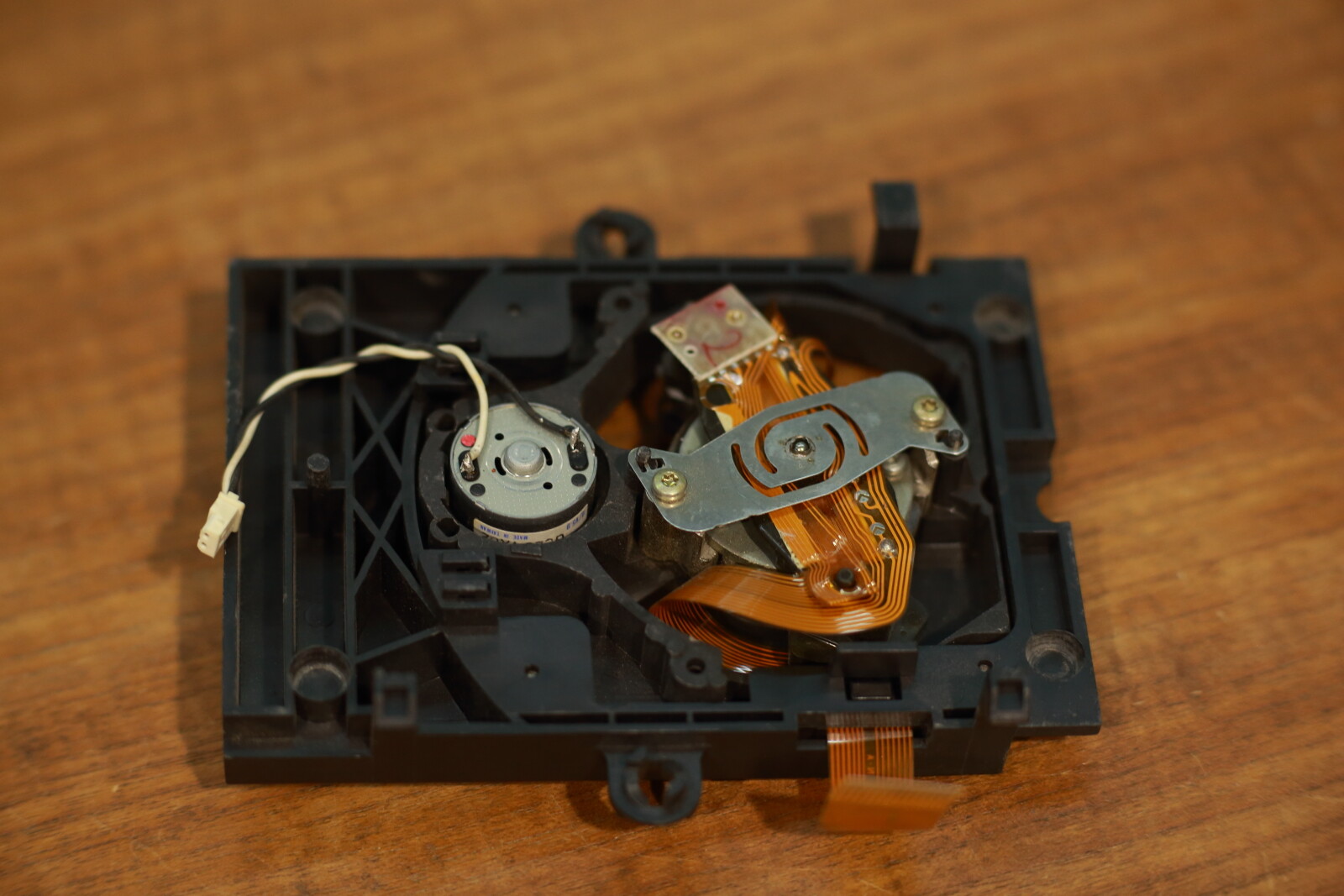

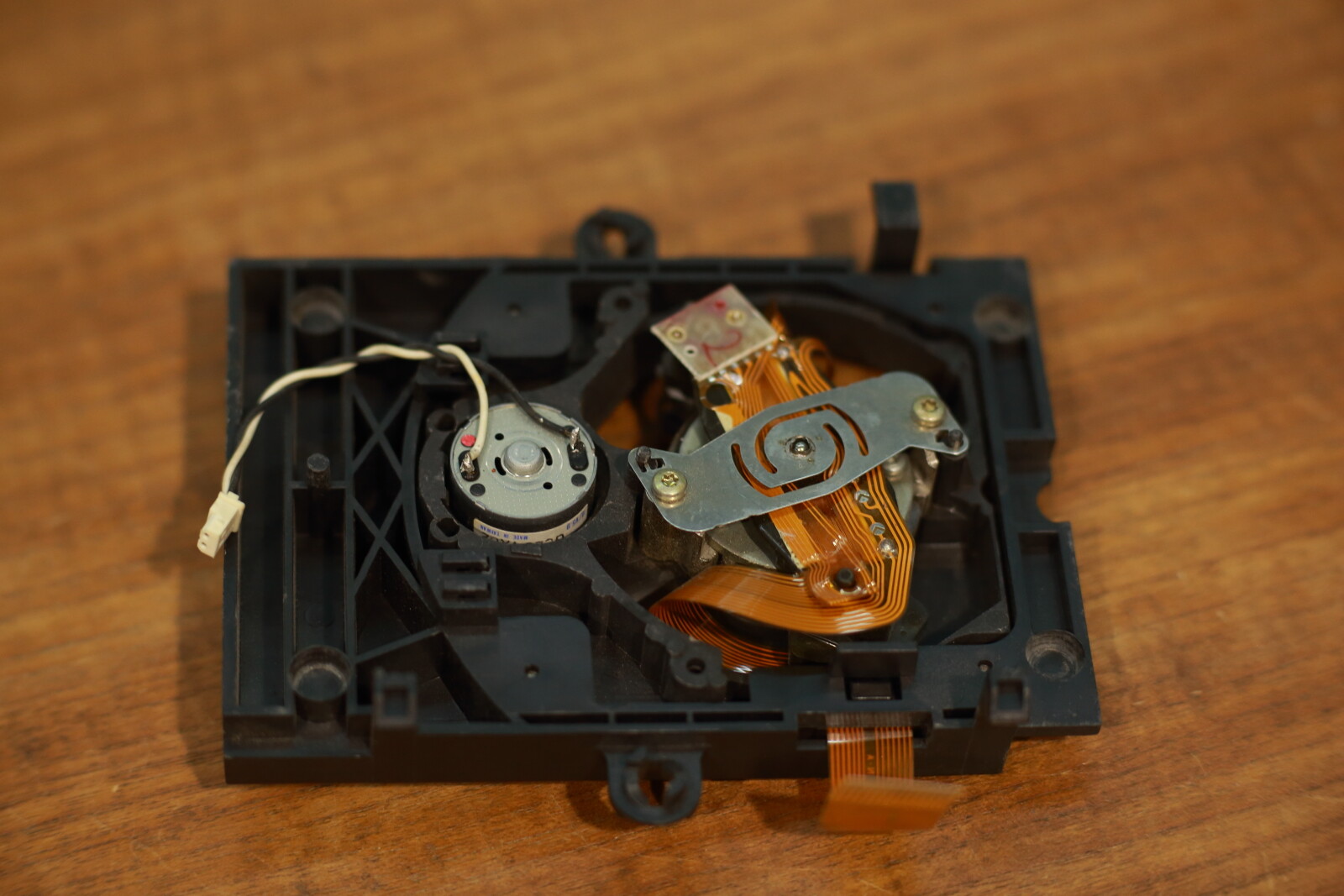

The bottom of the toy-type motor is sealed as seen here:

And the bottom has the press-fit spindle (which I'm told has a very tight and specific height adj, so you don't want to mess with it):

So where to oil (if motor lubing is reasonable to begin with)???

EDIT:

Maybe those tabs on the bottom need pulled back??

And the bottom has the press-fit spindle (which I'm told has a very tight and specific height adj, so you don't want to mess with it):

So where to oil (if motor lubing is reasonable to begin with)???

EDIT:

Maybe those tabs on the bottom need pulled back??

Last edited:

Thanks.Oil here,...

I am concerned about what the OTHER end of the commutator, as well as the brushes, look like 3+ decades after manuf./use ...

... are they worn out, dry, etc???

Last edited:

I would leave the brushes and commutator as is, you can't really do anything to either anyway and dismantling and assembling again isn't necessarily straight forward.

Unless it has a dead spot I'd stop at oiling the bushing.

Unless it has a dead spot I'd stop at oiling the bushing.

Before I used VdH TLF I or II oil, now I might perhaps use grease like MOLYKOTE® EM-30L which is great for CDM4/36 swing arm, tray rail etc. It's incredibly slippery stuff without being sticky and works better than silicone grease or graphite.

Last edited:

Molykote is great for many things, and I use it alot too, but it won't seep into a bushing like oil.

Many use regular synthetic motor oil like 0W30 or 5W30 for bearings/bushings. Some use gearbox oil as it doesn't contain agents like motor oil can/do.

Silicone or PTFE spray in a cup like starkeyg does is fine too, I do this myself from time to time too.

Anderol 456 is specifically for sintered bearings/bushings and widely used.

For something like this I use a turntable bearing oil (Phono 80) designed for bearings and bushings. Not because I know it's better, just because I have it and it's a very good oil for the purpose. This is not something that needs to be done regularly, only if the motor becomes noisy or - perhaps - every decade, maybe never.

Many use regular synthetic motor oil like 0W30 or 5W30 for bearings/bushings. Some use gearbox oil as it doesn't contain agents like motor oil can/do.

Silicone or PTFE spray in a cup like starkeyg does is fine too, I do this myself from time to time too.

Anderol 456 is specifically for sintered bearings/bushings and widely used.

For something like this I use a turntable bearing oil (Phono 80) designed for bearings and bushings. Not because I know it's better, just because I have it and it's a very good oil for the purpose. This is not something that needs to be done regularly, only if the motor becomes noisy or - perhaps - every decade, maybe never.

Swing arm lube

For my CDM-4/19 swingarm, I see only one ACCESSIBLE bearing/pivot point (see photo in prior post). There is another one at the top, but the SA has to be partly assembled to get access to that top bearing. If it's worth the trouble and the swing arm disassembly won't mess up some critical dimension (like the motor and spindle), I'm willing to do the job! Let me know!... great for CDM4/36 swing arm

I use higher-quality bicycle lube (Triflow, etc) for many things. That should work well. Boeshield (orig developed for aerospace ind) is another good product -- often used in high-end bikes, cars, etc.Molykote is great for many things, and I use it alot too, but it won't seep into a bushing like oil.

Many use regular synthetic motor oil like 0W30 or 5W30 for bearings/bushings. Some use gearbox oil as it doesn't contain agents like motor oil can/do.

Silicone or PTFE spray in a cup like starkeyg does is fine too, I do this myself from time to time too.

Anderol 456 is specifically for sintered bearings/bushings and widely used.

For something like this I use a turntable bearing oil (Phono 80) designed for bearings and bushings. Not because I know it's better, just because I have it and it's a very good oil for the purpose. This is not something that needs to be done regularly, only if the motor becomes noisy or - perhaps - every decade, maybe never.

Zoom Spout Turbine Oil - in a syringe, a drop will do, and you won't have any worries for years and years.

Turbine oil... ? If you CAN take you jumbo jet plane to work, does not say it´s optimal transport, if it is bicycle distance. The molycote EM-30L is as good as it can get, optimized for THIS application. In which parameters does "Zoom Spout Turbine Oil" exceed Molycote?

Originally the swingarm was lubricated with grease. I have used a bit of Molykote at the top and the bottom. Please be careful not to let the bearing balls role away! 😉. Use a hex key and gently lift and slide the metal plate to one side so you can take out the arm.

Turbine oil... ? If you CAN take you jumbo jet plane to work, does not say it´s optimal transport, if it is bicycle distance. The molycote EM-30L is as good as it can get, optimized for THIS application. In which parameters does "Zoom Spout Turbine Oil" exceed Molycote?

You have obviously misunderstood my post.

The light high quality oil is used for the motor bearings.

As for your molycote, I flush that crap off anything I service and use Super Lube grease instead.

After decades of doing professional servicing, I've settled on what works best, and lasts.

I am sure you know best. Sorry you got so upset. I used bearing oil before, but it seems to attract dirt and needs relubrication more often than grease.

Last edited:

For other lube applications, I use pure (industrial grade) 100% silicone liquid. You can buy it as a consumer thru mail or at a crafts store.

Sorry... Super Lube Grease for slow moving parts and Zoom Spout Turbine Oil for motor.

Sounds like titles for movies 🙂

Sounds like titles for movies 🙂

Again my question:

Why not putting a running motor, into warm thin oil over

night - mostly for cleaning purposes.. Then give it a rest

upside down on some Kleenex to get rid of the waste oil and dirt…?

Why not putting a running motor, into warm thin oil over

night - mostly for cleaning purposes.. Then give it a rest

upside down on some Kleenex to get rid of the waste oil and dirt…?

- Home

- Source & Line

- Digital Source

- Lubricating CD player's turntable motor (how often)