Hi

I was offered some 2nd hand ESLs which currently sound very good, but have had a lot of use, and were made by local guy here in Australia who has now retired. I asked the owner about long term serviceability. He replied:

“Long term serviceability is NIL. Alan Moss in poor health so cannot assist further. He has spare transformers which he might be persuaded to part with for the other two panels which I had stacked.

There are a couple of potential problems with the panels -

(1) the Mylar can "soften" and so give rise to a buzzing sound. Easily fixed by squirting a small amount of Silastic in to the offending part so it is effectively glued.

(2) the contact strip to the Mylar can lose contact. Not so easily fixed by using a little aluminium strip to the Mylar and changing the small wire to this instead of the original contact strip. This has been performed successfully on one panel.”

I don’t know much about ESL serviceability, but imagine the trannies could go (might they be dear?), but don’t know what other factors to consider – what might they be?

They’re interstate so I can’t inspect them now, but the guy is in our local Audio Club so I would get honest answers to any questions.

Thanks

I was offered some 2nd hand ESLs which currently sound very good, but have had a lot of use, and were made by local guy here in Australia who has now retired. I asked the owner about long term serviceability. He replied:

“Long term serviceability is NIL. Alan Moss in poor health so cannot assist further. He has spare transformers which he might be persuaded to part with for the other two panels which I had stacked.

There are a couple of potential problems with the panels -

(1) the Mylar can "soften" and so give rise to a buzzing sound. Easily fixed by squirting a small amount of Silastic in to the offending part so it is effectively glued.

(2) the contact strip to the Mylar can lose contact. Not so easily fixed by using a little aluminium strip to the Mylar and changing the small wire to this instead of the original contact strip. This has been performed successfully on one panel.”

I don’t know much about ESL serviceability, but imagine the trannies could go (might they be dear?), but don’t know what other factors to consider – what might they be?

They’re interstate so I can’t inspect them now, but the guy is in our local Audio Club so I would get honest answers to any questions.

Thanks

I have read further :

"Unfortunately this design has a weakness – the contact with the membrane becomes corroded and there is no simple repair.

It is being kept functioning at the moment by poking a wire through the mesh onto the mylar but that is not very satisfactory as any movement can cause shorting.”

How repairable is this??

Thanks

"Unfortunately this design has a weakness – the contact with the membrane becomes corroded and there is no simple repair.

It is being kept functioning at the moment by poking a wire through the mesh onto the mylar but that is not very satisfactory as any movement can cause shorting.”

How repairable is this??

Thanks

A typical ESL panel consists of two pieces of perforated aluminium, a plastic stator frame, and a tensioned diaphragm. The parts cost isn't high. What you're paying for is the ability to actually make it work. Many years ago I made ESL hadphones and had terrible trouble getting equal sensitivities. I've seen other ESL builders have the same problem.

View your loudspeakers as a "proof of concept" that may have to be totally rebuilt in the future and pay an appropriate price.

You have a considerable advantage in that it's a whole lot easier to make ESLs work in Oz than in damp Britain.

View your loudspeakers as a "proof of concept" that may have to be totally rebuilt in the future and pay an appropriate price.

You have a considerable advantage in that it's a whole lot easier to make ESLs work in Oz than in damp Britain.

Hi EC8010

(Melbourne winters in *southern Oz are not as bad as the UK, but they are often cloudy, drizzly & damp, and these speakers have always lived in Launceston, Aus - maybe similar to northern Portugal).

Yes, they are only about GBP 400 for a pair, but:

- They are a lot bulkier (1500 H * 570 W) than the West Australian ER Audio kits, which I was considering doing.

- More importantly, I do not want a "proof of concept".

I simply want something preferably 2nd hand commercial, not as much as Quads, that if need be - should be r* repairable.

Is it possible to say, without seeing them, how easy it could be to fix a contact with the membrane that’s corroded?

Thanks

(Melbourne winters in *southern Oz are not as bad as the UK, but they are often cloudy, drizzly & damp, and these speakers have always lived in Launceston, Aus - maybe similar to northern Portugal).

Yes, they are only about GBP 400 for a pair, but:

- They are a lot bulkier (1500 H * 570 W) than the West Australian ER Audio kits, which I was considering doing.

- More importantly, I do not want a "proof of concept".

I simply want something preferably 2nd hand commercial, not as much as Quads, that if need be - should be r* repairable.

Is it possible to say, without seeing them, how easy it could be to fix a contact with the membrane that’s corroded?

Thanks

Anything to do with the diaphragm is difficult. You'll have to make the final choice, but I wouldn't pay £400 for them in that condition.

Sorry to hear it's almost as soggy there as it is here...

Sorry to hear it's almost as soggy there as it is here...

Long term operability of ESLs has been one of my areas of interest for several years. Here's what I can tell you from my limited experience with my self-made ESLs and my Quad ESL-63s:

The main point of failure will always be the diaphragms. They are under very high mechanical tension. In my Quads, the diaphragms are failing one by one so I keep opening them up and replacing them as they go (4 per speaker). The failure mode is usually a split in the diaphragm along the edge of the insulator that supports the stators. I would expect this sort of failure in my self-built speakers as well, but they are not old enough yet.

The diaphragms don't loosen or soften on their own if they are made of polyester film which most or all commercial speakers use. What can happen is the adhesive that attaches the diaphragm to its frame can let go. Some speakers, like the Quads, use something like super-glue which does not properly bond with the diaphragm material. I am amazed they were able to actually ship the things without all the diaphragms popping loose.

Some more recently manufactured speakers use foam tape as diaphragm supports throughout the middle of the speaker. I have no experience with the specific tape they use, but I don't trust it to last more than a couple years. That stuff usually fails by hardening, then crumbling. Why anyone would make a speaker that way (or foam surrounds on woofers, for that matter) is beyond me.

The other common failure point is the HV bias supply. Sometimes in order to save a few cents the manufacturer will use diodes that are just able to withstand the voltages in the supply instead of using more conservatively rated parts. Forunately, the diodes are cheap and you can afford to replace them all should one fail.

Transformers fail occasionally, if you use a much too big power amp to try to drive the speakers to ear splitting volumes and burn them up. If you stay within the manufacturer's specs on the amp you'll probably never experience a transformer failure. In general transformers are extremely reliable components, even beating electric motors (their bearings eventually fail).

Diaphragm contacts are usually either a wire or metal foil strip embedded along the edge of the speaker inside the frame that supports the diaphragm. They can usually be easily replaced with some copper tape or wire or almost any other conductor. The diaphragm is usually glued to one side of the insulator frame, the side that doesn't have the contact, so you can usually disassemble the driver leaving the diaphragm in tact and repair the contact. Contacts corrode if the + terminal of the bias supply is connected to the diaphragm. I have found that by connecting the - terminal, the contact will not corrode.

Serviceablity is a question of your own ability and willingness to commit either the time to do the work yourself or the money to pay someone else to do it. Most of the problems can be fixed relatively easily and cheaply yourself if you are willing to learn a little and do the work. The materials and parts are pretty cheap, and uncritical in nature.

If the audio transformers are good, you can make the speaker work like new. If the audio transformers are bad, you can buy the speakers cheaply and use them as a basis for your own project.

See the web page at mark.rehorst.com for a DIY article (that needs to be updated) on making ESLs. The commercial ones work in exactly the same way as the home-made ones.

I_F

The main point of failure will always be the diaphragms. They are under very high mechanical tension. In my Quads, the diaphragms are failing one by one so I keep opening them up and replacing them as they go (4 per speaker). The failure mode is usually a split in the diaphragm along the edge of the insulator that supports the stators. I would expect this sort of failure in my self-built speakers as well, but they are not old enough yet.

The diaphragms don't loosen or soften on their own if they are made of polyester film which most or all commercial speakers use. What can happen is the adhesive that attaches the diaphragm to its frame can let go. Some speakers, like the Quads, use something like super-glue which does not properly bond with the diaphragm material. I am amazed they were able to actually ship the things without all the diaphragms popping loose.

Some more recently manufactured speakers use foam tape as diaphragm supports throughout the middle of the speaker. I have no experience with the specific tape they use, but I don't trust it to last more than a couple years. That stuff usually fails by hardening, then crumbling. Why anyone would make a speaker that way (or foam surrounds on woofers, for that matter) is beyond me.

The other common failure point is the HV bias supply. Sometimes in order to save a few cents the manufacturer will use diodes that are just able to withstand the voltages in the supply instead of using more conservatively rated parts. Forunately, the diodes are cheap and you can afford to replace them all should one fail.

Transformers fail occasionally, if you use a much too big power amp to try to drive the speakers to ear splitting volumes and burn them up. If you stay within the manufacturer's specs on the amp you'll probably never experience a transformer failure. In general transformers are extremely reliable components, even beating electric motors (their bearings eventually fail).

Diaphragm contacts are usually either a wire or metal foil strip embedded along the edge of the speaker inside the frame that supports the diaphragm. They can usually be easily replaced with some copper tape or wire or almost any other conductor. The diaphragm is usually glued to one side of the insulator frame, the side that doesn't have the contact, so you can usually disassemble the driver leaving the diaphragm in tact and repair the contact. Contacts corrode if the + terminal of the bias supply is connected to the diaphragm. I have found that by connecting the - terminal, the contact will not corrode.

Serviceablity is a question of your own ability and willingness to commit either the time to do the work yourself or the money to pay someone else to do it. Most of the problems can be fixed relatively easily and cheaply yourself if you are willing to learn a little and do the work. The materials and parts are pretty cheap, and uncritical in nature.

If the audio transformers are good, you can make the speaker work like new. If the audio transformers are bad, you can buy the speakers cheaply and use them as a basis for your own project.

See the web page at mark.rehorst.com for a DIY article (that needs to be updated) on making ESLs. The commercial ones work in exactly the same way as the home-made ones.

I_F

Asa side note, 400GBP (about US$750) is more than enough to get a nice set of Acoustats...

Given the situation here, if I couldn't find Acoustats in Oz, I'd just buy some transformers, eggcrate, wire, and polyester film and build my own; you're going to end up doing that anyway, and $750 is a whole lot of money for two transformers and some stators.

Given the situation here, if I couldn't find Acoustats in Oz, I'd just buy some transformers, eggcrate, wire, and polyester film and build my own; you're going to end up doing that anyway, and $750 is a whole lot of money for two transformers and some stators.

Hi I_F

Thanks, excellent information!

At what age have you found diaphragm failure begins at? Is the symptom – loss of sound from that one diaphragm, or the whole speaker?

> I have found that by connecting the - terminal, the contact will not corrode.

. . and there are no –ve effects (pun intended)?

You’d have to very lucky to get Acoustats here. I had been considering doing an ER Audio kit.

BTW, I paid a deposit on these just half an hour before seeing these last 3 posts!

The speakers are 8 years old, 7 segment, 7 sq feet (0.7 m2) per speaker, with lead lining on the timber frames. About 86 dB down to 250-300 Hz. (There is Mylar in their construction; I believe the diaphragm).

For $US 870 I also got a pair of 15 years old (one rebuilt later) spare panels and spare transformer & two circuit boards + circuits from the maker.

By buying something made, my time is freed for (too many) other projects . .

deposit paid > too late now . . . how does that sound for value?

Regards

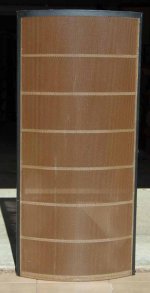

they wouldn't win beauty awards close up, they sound *very *nice

Thanks, excellent information!

At what age have you found diaphragm failure begins at? Is the symptom – loss of sound from that one diaphragm, or the whole speaker?

> I have found that by connecting the - terminal, the contact will not corrode.

. . and there are no –ve effects (pun intended)?

You’d have to very lucky to get Acoustats here. I had been considering doing an ER Audio kit.

BTW, I paid a deposit on these just half an hour before seeing these last 3 posts!

The speakers are 8 years old, 7 segment, 7 sq feet (0.7 m2) per speaker, with lead lining on the timber frames. About 86 dB down to 250-300 Hz. (There is Mylar in their construction; I believe the diaphragm).

For $US 870 I also got a pair of 15 years old (one rebuilt later) spare panels and spare transformer & two circuit boards + circuits from the maker.

By buying something made, my time is freed for (too many) other projects . .

deposit paid > too late now . . . how does that sound for value?

Regards

they wouldn't win beauty awards close up, they sound *very *nice

Attachments

Curved panels are MUCH harder to rebuild. The tensioning has to be done in a tricky way; there's a nice addendum in Roger Sanders's ESL construction book.

To this point, I am totally unconvinced that the curvature has much sonic (as opposed to visual) advantage.

To this point, I am totally unconvinced that the curvature has much sonic (as opposed to visual) advantage.

Thanks for the reality check.

However spares are included, I would only need rebuild if the spares stuff up too . .

Cheers

However spares are included, I would only need rebuild if the spares stuff up too . .

Cheers

Hi,

rebuilding a curved panel doesn´t need to be much harder at all.

It´s no big deal as long as You build a curved tensioning frame and work with apropriate care.

The curvature leads to much less rattle of the panel because of higher structural integrity. Dispersion is broadend a bit too.

jauu

Calvin

rebuilding a curved panel doesn´t need to be much harder at all.

It´s no big deal as long as You build a curved tensioning frame and work with apropriate care.

The curvature leads to much less rattle of the panel because of higher structural integrity. Dispersion is broadend a bit too.

jauu

Calvin

Calvin

> a curved tensioning frame and work with appropriate care

Are there any good links/ tips on this?

Cheers

> a curved tensioning frame and work with appropriate care

Are there any good links/ tips on this?

Cheers

Hi

afaik no. But building curved panels on my own, I think I know what I´m talking about 🙂

jauu

Calvin

afaik no. But building curved panels on my own, I think I know what I´m talking about 🙂

jauu

Calvin

Calvin said:Hi,

rebuilding a curved panel doesn´t need to be much harder at all.

It´s no big deal as long as You build a curved tensioning frame and work with apropriate care.

The curvature leads to much less rattle of the panel because of higher structural integrity. Dispersion is broadend a bit too.

jauu

Calvin

It is said by some that curved panels increase distortion by a small but noticable level because of the unavoidable front and back differences in the tensioning of the diaphragm.

My only experience with curved panels were the original Martin Logan CLS which were not even in the same ballpark with my first electrostats (and best ever speakers) Dayton Wrights.

GeorgeJ

The theory of curved esls suffering from distortion is wrong in my opinion since it is based on the model of a curved membrane being a part of a circle while it is part of a cylinder in reality.

In other words the 'distortion theory' forgets the length direction which provides the dominant and lineair part of forces.

In other words the 'distortion theory' forgets the length direction which provides the dominant and lineair part of forces.

I think curved or flat, both electrostats can have distortion so much lower than conventional drivers. IMHO the biggest weakness of electrostats is small sweet spot.

One reason I chose curved is their moderately better dispersion. The curved Moss are less critical in this area than Quads.

Cheers

One reason I chose curved is their moderately better dispersion. The curved Moss are less critical in this area than Quads.

Cheers

rick57 said:I think curved or flat, both electrostats can have distortion so much lower than conventional drivers. IMHO the biggest weakness of electrostats is small sweet spot.

One reason I chose curved is their moderately better dispersion. The curved Moss are less critical in this area than Quads.

Cheers

I partially agree about the sweet spot unless you are only one serious listener like me. In my case I think the small sweet spot is a plus.

More bothersome to me is the somewhat resonant quality I hear in voices, and solo trumpets and violins, which is I think called "plastic coloration" by some. I heard it from the Martin Logans and now from a pair of hybrid Just Real Music panels.

But all in all, everytime I go back to conventional speakers, it is not long before I set up the electrostats again.

GeorgeJ

Not serviceability, but I see the 2nd top Soundlab model now uses toroids:

www.soundlab-speakers.com/u1.htm

"The toroidal transformer is more expensive to manufacture than the stacked type. However, in the quest for highest signal accuracy, there is no substitute."

Note the last spec on the page: $ I guess Soundlab had to pay for the toroids.

I guess Soundlab had to pay for the toroids.

(This is the model * “below” * the Soundlab model, that the guy who sold me the Moss has now bought).

Cheers

www.soundlab-speakers.com/u1.htm

"The toroidal transformer is more expensive to manufacture than the stacked type. However, in the quest for highest signal accuracy, there is no substitute."

Note the last spec on the page: $

I guess Soundlab had to pay for the toroids.

I guess Soundlab had to pay for the toroids. (This is the model * “below” * the Soundlab model, that the guy who sold me the Moss has now bought).

Cheers

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Long term serviceability of ESLs