1) Does anyone know the specs?

2) Did anyone ever make aftermarket transformers? If so, who?

3) Did anyone ever find off the shelf part(s) to sub in for a failed high voltage winding? If so, what?

4) Does anyone actually have available stock?

Thanks.

2) Did anyone ever make aftermarket transformers? If so, who?

3) Did anyone ever find off the shelf part(s) to sub in for a failed high voltage winding? If so, what?

4) Does anyone actually have available stock?

Thanks.

Short version:

The insulation within the secondary winding is not really up to the best standards... Many transformer fails in those speakers, and if you look at the schematic there is actually 3200 volts on this winding. And add to that the peak voltage of the mains you get 3400volt in peak between windings.

This voltage is of course lethal!

This means that you will probably DIE! If you touch the parts within the enclosure of this amplifier and there is charge left on the capacitors!!

And I do NOT recommend anyone to experiment with this amplifier. Let the experts handle this. If you ever find anyone who have proper certificate... I doubt.

The only aftermarket transformer I would use is from microwave ovens.

Same here... dangerous stuff!

I did some tries to vacuum impregnate one transformer, i built a vacuum chamber, found a 2 component insulation liquid that hardens, i heated up the transformer to 70 deg C to lower the viscosity and put several vacuum compressors in series, and managed to reach <5mBar.

The transformer was put in a plastic bag, and i filled the bag with the resin. Put it in the chamber, and kept the vacuum until it started to get really thick. Then i let the pressure in and scraped of the outer surface from not yet hardened impregnation.

I put the transformer back in operation and YES!

It worked, for a couple of months.. I should have tried with even better vacuum and higher temperature, and maybe with lower viscosity...

But the cracking noise started again and I knew that a new transformer was needed.

There is another option and that is to take an ordinary microwave oven transformer and rewind it.

Where do you live?

The insulation within the secondary winding is not really up to the best standards... Many transformer fails in those speakers, and if you look at the schematic there is actually 3200 volts on this winding. And add to that the peak voltage of the mains you get 3400volt in peak between windings.

This voltage is of course lethal!

This means that you will probably DIE! If you touch the parts within the enclosure of this amplifier and there is charge left on the capacitors!!

And I do NOT recommend anyone to experiment with this amplifier. Let the experts handle this. If you ever find anyone who have proper certificate... I doubt.

The only aftermarket transformer I would use is from microwave ovens.

Same here... dangerous stuff!

I did some tries to vacuum impregnate one transformer, i built a vacuum chamber, found a 2 component insulation liquid that hardens, i heated up the transformer to 70 deg C to lower the viscosity and put several vacuum compressors in series, and managed to reach <5mBar.

The transformer was put in a plastic bag, and i filled the bag with the resin. Put it in the chamber, and kept the vacuum until it started to get really thick. Then i let the pressure in and scraped of the outer surface from not yet hardened impregnation.

I put the transformer back in operation and YES!

It worked, for a couple of months.. I should have tried with even better vacuum and higher temperature, and maybe with lower viscosity...

But the cracking noise started again and I knew that a new transformer was needed.

There is another option and that is to take an ordinary microwave oven transformer and rewind it.

Where do you live?

I have ordered these on specification but the manufacturer did not grasp the idea so they went up in smoke after one hour of use. Then i decided to have seperate transfomers wound. This worked finally. Make sure you do not use a voltage doubler circuit as the insulation between the primary and secondary could be no good after all. The next thing i found is that the space between the copper wires and the iron core was very small as well.

Now this could be a bad manufacturer or just not thought thrue when winding them.

I have now build several HV amps (Acoustat and Beveridge replacements) with very good results and no failurs for more then 15 years now.

Now this could be a bad manufacturer or just not thought thrue when winding them.

I have now build several HV amps (Acoustat and Beveridge replacements) with very good results and no failurs for more then 15 years now.

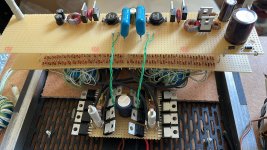

Attachments

That is a challenge as not many manufacturers understand the specs. ( i speak of experience).

Look at the distance between solder lip and the metalwork. They should be ashamed to produce somthing like this. Naturally this transformer died within 15 minutes. I didn’t get any refund as well (very known manufacturer here in Holland).

So now i use seperate transformers dedicated to the task without any issues.

Look at the distance between solder lip and the metalwork. They should be ashamed to produce somthing like this. Naturally this transformer died within 15 minutes. I didn’t get any refund as well (very known manufacturer here in Holland).

So now i use seperate transformers dedicated to the task without any issues.

Attachments

Yes thats the way to go. Disconnect the HV secondary, and buy a separate transformer for 3200V I know people here in Sweden who has done that.

I worked a lot on Bev 2SW in the late 70s early 80s both in Stockholm and Oslo and the amps were tricky.....I was at Siemens at the time and after I was allowed to buy their 8KV x-ray diodes, they behaved.....I once got 3kV in my wrist because + was to gnd...the bacon smell was prominent...ha-ha

hi

no I studied in Stockholm and met an artist who got Bevs and there I also got to know Kavi Alexander who also had a pair......when I got back to Oslo I had another friend with a pair as well..that´s when I got the Siemens diodes

unfortunately never met Harold

Btw Leif Hãggmark has since then been a friend for close to 40 years

no I studied in Stockholm and met an artist who got Bevs and there I also got to know Kavi Alexander who also had a pair......when I got back to Oslo I had another friend with a pair as well..that´s when I got the Siemens diodes

unfortunately never met Harold

Btw Leif Hãggmark has since then been a friend for close to 40 years

Impressive @Lampie519 - if you originally went to the trouble of winding transformers

What were the specifications?

Thanks.

What were the specifications?

Thanks.

Winding transformers is not my thing except RF transformers.

I like my transformers over-engineerd so i can rely on them. No mechanical hum, stay cool under load, good isolation between windings etc.

Now i am using more and more RF transformers as the are small and can be handwound to specification. All you need is a RF source. A lot of space can be saved on the board plus free of any mains dirt.

I like my transformers over-engineerd so i can rely on them. No mechanical hum, stay cool under load, good isolation between windings etc.

Now i am using more and more RF transformers as the are small and can be handwound to specification. All you need is a RF source. A lot of space can be saved on the board plus free of any mains dirt.

Attachments

- Home

- Loudspeakers

- Planars & Exotics

- Let's talk Beveridge 2/2SW power transformers