Hello, I am trying to repair a Phillips D8128 radio for my father, a few months ago the drive cord for the station search came out. Since the cord is worn in one place, thinking to replace it, he took it out of its place, he didn't go back on it and since then forgot how the cord was positioned mainly on the white wheel. I have no idea how to wrap the wire around the white wheel, would you know where I could find documentation, pictures even of another equivalent model or with the same type of wheel that could help me I would be delighted because apart from that the radio works very well. The Phillips D8120 model also seems to have the same station winding system but again it is difficult to find a doc showing how to wind.

Sincerely

Sincerely

Attachments

Hello, I want to send you a HUGE thank you. Even if it's not exactly my model, this video helped me a lot, I don't have a spring on my radio but I'm making progress despite everythingVideo showing the 8120. You can make out some of the winding details.

Might be why it came off in the first place. I’ve had missing springs and had to just put the cord on “too tight” and force it on to the pulleys, only to have it come back off again when tuning the radio near the ends of the band. The tension doesn’t stay constant with the small changes in angle if it’s just tied on.

Maybe you can repurpose a small ballpoint pen spring, it´s about the right size.

Not too strong but better than nothing.

Not too strong but better than nothing.

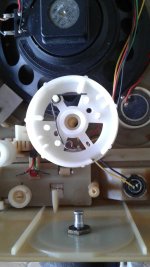

Hello, the link provided by Mattstat helped me a lot, I was able to make the complete circuit, I thought I had won, I started the reassembly and then ... finally the white wheel does not drive the black selector of the electronic board.

The external wheel does not do its job, it turns in the empty and the cord is not driven.

Maybe indeed that this spring is essential to ensure the necessary tension, for lack of being able to buy the same one I will try to make one for myself.

The external wheel does not do its job, it turns in the empty and the cord is not driven.

Maybe indeed that this spring is essential to ensure the necessary tension, for lack of being able to buy the same one I will try to make one for myself.

Attachments

Should I put the cord through the spring first or should I wait until I reach the level of the outer wheel, so towards the end of the circuit to place it?

A small tension spring might fit.

Whatever you do, ensure the tuning is capable of full travel before committing.

Whatever you do, ensure the tuning is capable of full travel before committing.

Hello, so some news... I made a spring I don't know if it's reliable but I still can't tension this cord 🙁

I only managed once to tension it but only in one direction but when I went back the cord sometimes relaxed to the point of leaving the circuit.

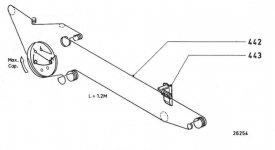

There is a double pulley system, I wind the cord at the top and at the bottom, using the plan of a similar model, the TR1842, as a guide for the cord,, I do not know where it sticks.

This mechanism is really annoying and I can't count on Philips technical service, they didn't even have any documentation to give me

If you have an idea?...

I only managed once to tension it but only in one direction but when I went back the cord sometimes relaxed to the point of leaving the circuit.

There is a double pulley system, I wind the cord at the top and at the bottom, using the plan of a similar model, the TR1842, as a guide for the cord,, I do not know where it sticks.

This mechanism is really annoying and I can't count on Philips technical service, they didn't even have any documentation to give me

If you have an idea?...

Attachments

I'm not an expert on stringing radios but have done similarly challenging jobs.

1 - be in the right frame of mind - when you feel like throwing it across the room, stop, make a cup of tea, chill, go back when ready.

2 - some pulleys will have only 1 to 1-1/2 turns on at one extreme of the tuning range and multiple turns when at the other end of the range. Getting this right can be tricky.

3 - before stringing, check pulleys for damage and ensure they spin on the shafts freely but without excess wear in the bores. If a bore has worn so the pulley wobbles you are on a hiding to nothing.

4 - does your spring behave as it should - is it springy? If in doubt, although the original is a torsion (bent wire) spring, a tension spring may be a satisfactory substitute - as long as it keeps the cord tight.

1 - be in the right frame of mind - when you feel like throwing it across the room, stop, make a cup of tea, chill, go back when ready.

2 - some pulleys will have only 1 to 1-1/2 turns on at one extreme of the tuning range and multiple turns when at the other end of the range. Getting this right can be tricky.

3 - before stringing, check pulleys for damage and ensure they spin on the shafts freely but without excess wear in the bores. If a bore has worn so the pulley wobbles you are on a hiding to nothing.

4 - does your spring behave as it should - is it springy? If in doubt, although the original is a torsion (bent wire) spring, a tension spring may be a satisfactory substitute - as long as it keeps the cord tight.

- Home

- General Interest

- Everything Else

- How to reattach the station search cord?