Hello,

We got a little bored today, with nothing better to do on a Saturday afternoon, and decided to try making a capacitor from some paper and some tin foil. Using the capacitance formula (taking into account the distance between plates, area, and dialectric constant) I found an A4 sized pair of plates (kitchen foil) and paper dialectric (0.12mm thick, just ordinary A4 paper) should give around 16nF ish.

Well we made it, and the best way we could think of testing it was to use it in an RC high pass filter. We tried it and according to the java program on this page the actual capacitance was around 20nF. I think that's quite encouraging and was wondering about the feasibility of actually building some nice usable caps, maybe making some nice cans for them to sit in and using copper foil. It seems these would be ideal for interstage coupling caps in tube circuits (my amp has 100nF here, and a 100pF in the NFB loop)

Just a few questions, what effect would it have using oil (and what type of oil to use) like for example Audio Note PIO's.

Also is there any way of telling what kind of voltage they would be able to take? This is the main thing I'm scared of with using these. I guess the thickness of the paper would be the main issue here? Maybe the oil helps in PIO's?

Cheers for all your help,

Steve

We got a little bored today, with nothing better to do on a Saturday afternoon, and decided to try making a capacitor from some paper and some tin foil. Using the capacitance formula (taking into account the distance between plates, area, and dialectric constant) I found an A4 sized pair of plates (kitchen foil) and paper dialectric (0.12mm thick, just ordinary A4 paper) should give around 16nF ish.

Well we made it, and the best way we could think of testing it was to use it in an RC high pass filter. We tried it and according to the java program on this page the actual capacitance was around 20nF. I think that's quite encouraging and was wondering about the feasibility of actually building some nice usable caps, maybe making some nice cans for them to sit in and using copper foil. It seems these would be ideal for interstage coupling caps in tube circuits (my amp has 100nF here, and a 100pF in the NFB loop)

Just a few questions, what effect would it have using oil (and what type of oil to use) like for example Audio Note PIO's.

Also is there any way of telling what kind of voltage they would be able to take? This is the main thing I'm scared of with using these. I guess the thickness of the paper would be the main issue here? Maybe the oil helps in PIO's?

Cheers for all your help,

Steve

Attachments

I have got to say that this is the ultimate DIY. Making your own components is definately the pinnacle. Congratulations on your success. I can't think of any reason why your scheme using mineral oil would not work. You would have to do some tests to determine the working voltage though.😀

Thanks 🙂

Hmmmm, any ideas on how to determine the voltage capabilities of it without resorting to destructive testing? which i dont really fancy to be honest.

Thanks,

Steve

Hmmmm, any ideas on how to determine the voltage capabilities of it without resorting to destructive testing? which i dont really fancy to be honest.

Thanks,

Steve

That is the DIY spirit, but you are not the first one to make them.

My father used to make his own caps in about the same way

when I was a child. To be even more cheap, he even

reused the foil wrapped around pieces of chocolate. 🙂

My father used to make his own caps in about the same way

when I was a child. To be even more cheap, he even

reused the foil wrapped around pieces of chocolate. 🙂

Measure the core temperature onder load, then you just read the voltage when the cap is at the max temperature you dare 😀

Just to follow the forum rules about safety...do this with the cap behind something solid and heat resistant!!!

Magura🙂

Just to follow the forum rules about safety...do this with the cap behind something solid and heat resistant!!!

Magura🙂

Hi,

So temperature should really be the main issue here then?

Is it ok to use dry paper? or is the oil just used to stop the copper tarnishing? and/or change the dialectric constant?

Any clues as to what thickness copper foil would be good, though i'm guessing that depends on factors like voltage rating. I also need a source for copper foil 🙁 or i could just keep on using kitchen foil....🙂

Cheers again,

Steve

So temperature should really be the main issue here then?

Is it ok to use dry paper? or is the oil just used to stop the copper tarnishing? and/or change the dialectric constant?

Any clues as to what thickness copper foil would be good, though i'm guessing that depends on factors like voltage rating. I also need a source for copper foil 🙁 or i could just keep on using kitchen foil....🙂

Cheers again,

Steve

The main purpose of the oil is to increase the heat transfer. The voltage is determined by heat and when the cap sparks over. The foil thickness determines the load the cap can take...I think.

Magura🙂

Magura🙂

No, I don't think temperature determines the voltage capability

here. Rather it is the type of dielectric and its thickness. Since

you are using paper, humidity also enters the equation so I

think it would matter alot if you can dry them and then seal

them compared to just using them as they are. While temperature

is not important, you will probably not use such a capacitor in

a place where temperature will be the limiting factor. It seldom

is for film capacitors.

here. Rather it is the type of dielectric and its thickness. Since

you are using paper, humidity also enters the equation so I

think it would matter alot if you can dry them and then seal

them compared to just using them as they are. While temperature

is not important, you will probably not use such a capacitor in

a place where temperature will be the limiting factor. It seldom

is for film capacitors.

Hello,

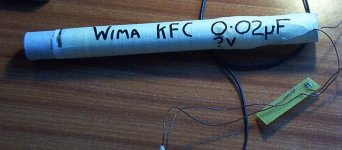

Well the wima's that are in that position in my amp at the moment are fairly small (polystyrene btw) and they aren't noticably hotter than their surroundings to the touch. Are there any hard and fast rules anyone knows of for what thickness paper I would need to use for a given voltage?

Steve

Well the wima's that are in that position in my amp at the moment are fairly small (polystyrene btw) and they aren't noticably hotter than their surroundings to the touch. Are there any hard and fast rules anyone knows of for what thickness paper I would need to use for a given voltage?

Steve

http://uk.farnell.com/jsp/catalog/viewproductdetails.jsp;jsessionid=O3PMMBJNCDZ5HQFIAEXCFE4AVAAS2IV3?prodId=187896

Any thoughts as to how well this stuff would work?

Steve

Any thoughts as to how well this stuff would work?

Steve

You can usually find data about paper and various other

dielectrica in introductory textbooks, some component

catalogues etc. However, paper is a very broad concept

and paper comes in so many types and varieties that it

is probably dangerous to use such data.

dielectrica in introductory textbooks, some component

catalogues etc. However, paper is a very broad concept

and paper comes in so many types and varieties that it

is probably dangerous to use such data.

Yes, specially with coated paper and recycled paper etc... but i was still surprised how close the actual capacitance measured came to matching my calculated capacitance 🙂 Even so, I think I'll talk nicely to some of the lecturers up at uni and see if they have any thoughts on testing...

Steve

Steve

I used to make caps out of mylar sheets and aluminum foil back in highschool(20yrs ago). The voltage rating is determined by the dielectric material and thickness. To give you an idea, we used to use the covers of those folders used to turn in written reports, a fairly thick plastic and regular aluminum foil. We were able to charge it with a Van De Graf generator at over 10000 volts with no problem. We'd leave it on the desk of some unsuspecting soul and they would pick it up out of curiosity and BANG! No deaths occurred

Hehe, oh the old days (only about 5 years ago for me  ) An old trick for us was to turn monitors on and off over and over again with your feet off the ground and a hand on the screen.......then touch someone 😉 no idea how that one worked though. Hmm, maybe one sheet of 0.12mm paper will be up to it then...will try and find out.

) An old trick for us was to turn monitors on and off over and over again with your feet off the ground and a hand on the screen.......then touch someone 😉 no idea how that one worked though. Hmm, maybe one sheet of 0.12mm paper will be up to it then...will try and find out.

Steve

) An old trick for us was to turn monitors on and off over and over again with your feet off the ground and a hand on the screen.......then touch someone 😉 no idea how that one worked though. Hmm, maybe one sheet of 0.12mm paper will be up to it then...will try and find out.

) An old trick for us was to turn monitors on and off over and over again with your feet off the ground and a hand on the screen.......then touch someone 😉 no idea how that one worked though. Hmm, maybe one sheet of 0.12mm paper will be up to it then...will try and find out.Steve

Originaly posted by: baggystevo82

So temperature should really be the main issue here then?

Yes it's an important issue, I may be wrong, but I think the leakage current would play an important role here in determining the maximum voltage rating.

I've DIY'ed a few caps with aluminum foil and good ol' Scotch Magic Transparent tape, the green plaid stuff not the red! Even tried the foil/paper liners from cigarette packs! The edges where the challenging part. But I never used them where they were exposed to high voltage.

And also getting an even and tight winding is another factor.

Wayne

baggystevo82 said:Hehe, oh the old days (only about 5 years ago for me) An old trick for us was to turn monitors on and off over and over again with your feet off the ground and a hand on the screen.......then touch someone 😉 no idea how that one worked though. Hmm, maybe one sheet of 0.12mm paper will be up to it then...will try and find out.

Steve

Have you ever seen the long strips of tinsel that are sold at christmas time? (not the furry rope type tinsel, but the single strand stuff)

Take two of these and cross them over on the screen of a CRT TV (large is preferable) and get someone to put their finger in the centre - then simply turn the TV on.

Also holding the spark plug of a lawnmower while someone is pulling the starter cord has the same effect.

Remember kids DON'T TRY THIS AT HOME elastic-trickery is extremely dangerous! We wouldn't want anyone getting killed!

...and with regards to the homemade cap. I have a simple suggestion.

Capacitance is proportional to both the dielectric constant of the medium between the plates, the area of the plates and the distance between the plates.

Increasing the area and dielectric constant will increase the capacitance and, conversely, increasing the distance will decrease the capacitance.

C= (Epsilon x Area)/Distance

My idea was to lay a sheet of tin foil out as flat as possible, then spray it with a few coats of laquer, then lay the other sheet on top and roll it up - this will hopefully allow you to minimise the distance between the plates. If laquer doesn't work you can try all manner of dielectrics - a little research will help.

Capacitance is proportional to both the dielectric constant of the medium between the plates, the area of the plates and the distance between the plates.

Increasing the area and dielectric constant will increase the capacitance and, conversely, increasing the distance will decrease the capacitance.

C= (Epsilon x Area)/Distance

My idea was to lay a sheet of tin foil out as flat as possible, then spray it with a few coats of laquer, then lay the other sheet on top and roll it up - this will hopefully allow you to minimise the distance between the plates. If laquer doesn't work you can try all manner of dielectrics - a little research will help.

Hehe, lawnmowers would be VERY dodgy! As many of these small garden engines have weird electronic ignitions that sometimes have very high outputs at low revs.

Steve

In my one i just made sure that the paper was about an inch wider than the foil, and then just tried to lay the second sheet of foil in line with the first as best i could.The edges where the challenging part

I did consider cling film for a while, but decided it would change its properties too much when it gets hot. I think tracing paper might work well, or just very lightweight normal paper, assuming it will still cope with the pd accross it ok....and with regards to the homemade cap. I have a simple suggestion.

Capacitance is proportional to both the dielectric constant of the medium between the plates, the area of the plates and the distance between the plates.

Increasing the area and dielectric constant will increase the capacitance and, conversely, increasing the distance will decrease the capacitance.

Steve

Make the foils 1/2" wider than the paper an offset one to the right and the other to the left. This will give you an easy way to connect the ends then wrap the whole thing in a larger wrapper to cover it all. Roll it up as tightly as you can using a small rod as a former. Tape the foils to the dielectric on the inside end of the roll so they dont move when you roll it. Mylar sheeting is better than paper if you can get it thin enough. Keep the roll tight to maximize the value.

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- Home made capacitors