In 1963 i started to make some different assembling, i show them to friends and they laugh as a hell...... was a noisy hahahaha...hohoho....hhuhuhu.... and i telling them, no!, assembling this side is not crazy, it is easy, faster, better and will be the future.... they said i was lazy, because not holes, not inverted images in copper circuit board downside... they said...have to make holes.... board have holes.... have to solder other side, solder is made other side...and i telling them WHY?

When SMD appear, components horizontal, flat, as i done before, no more laugh!.... where are those friends?.... only one i met, this one remember and congratulates me.

I have not good knowledge related electronics, also i do not know how to transform in money some good crazy ideas...but always having ideas, and discussing the "status quo".... all the things people do not like to discuss i am always checking, because always i can find mistakes...people repeat others do without think about that.

Second i decide to construct one unequalizer, 8 stereo channels plus and less 12 dB controler.... to match the sound to my furniture, carpets and damn speaker (all them bull S--t)....again hahahahahaha!.... try to sale idea in bigger capital and hohohoho.... this way i made mine and forgot those thing.... one year and appear the Japanese Equalizer..... and i became nervous.... not equalizer!...the music came already equalized, equal the levels.... that's he meaning... this machine unequalize...not equalize..... i found the friends... and they respect me because i had first the idea.

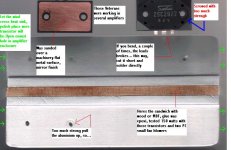

Now the wind tunnel, the small fans i have them in trash.... in cities giant trash... i paid people and they separe to me..... go to soap and air with pressure... and them i test them when dried.... can buy 50 for a dollar...normally can have one third good to use, without noise, and good looking ones, without rust.... this way small aluminium in sandwich, one fan each side.... if inside a wooden tunnel better, but more noise..... open will work reasonable too..... inside enclosure, size diminishes, only two holes, same fan size its ok....one to input wind other to output wind... a small sandwiched heatsink can hold 150 watts of heat easy....in my environment this one without fans will dissipate 30 watts more or less... take a look, a 75 RMS power amplifier can have this size.... glue the small board into the heat sink, two small microprocessor fans, and a outside tube... excluding supply, and somepeople can make supply smaller than that (EVA and many others), you can have less material, less weigth, and please, forgive me you all friends..... those insulators....i am sorry, but a hell with them!...no need this thermical resistance.... put transistor directly in heatsink!.... small conical automatic screw... the one that will make his rails.... and ready to put power on it!

Isolate the plus side related the minus side with wood, and also this tunnel sink related the metal or wooden or plastic chassis you have.... simple, cheaper, smaller.

I am sure, if not happen already... tomorrow you will not laugh from Destroyer...i am sure about that.

regards you all hahahahahaha...... i will be the last to make that.... and this is the best moment....huhuhu...hohohô!

Carlos

When SMD appear, components horizontal, flat, as i done before, no more laugh!.... where are those friends?.... only one i met, this one remember and congratulates me.

I have not good knowledge related electronics, also i do not know how to transform in money some good crazy ideas...but always having ideas, and discussing the "status quo".... all the things people do not like to discuss i am always checking, because always i can find mistakes...people repeat others do without think about that.

Second i decide to construct one unequalizer, 8 stereo channels plus and less 12 dB controler.... to match the sound to my furniture, carpets and damn speaker (all them bull S--t)....again hahahahahaha!.... try to sale idea in bigger capital and hohohoho.... this way i made mine and forgot those thing.... one year and appear the Japanese Equalizer..... and i became nervous.... not equalizer!...the music came already equalized, equal the levels.... that's he meaning... this machine unequalize...not equalize..... i found the friends... and they respect me because i had first the idea.

Now the wind tunnel, the small fans i have them in trash.... in cities giant trash... i paid people and they separe to me..... go to soap and air with pressure... and them i test them when dried.... can buy 50 for a dollar...normally can have one third good to use, without noise, and good looking ones, without rust.... this way small aluminium in sandwich, one fan each side.... if inside a wooden tunnel better, but more noise..... open will work reasonable too..... inside enclosure, size diminishes, only two holes, same fan size its ok....one to input wind other to output wind... a small sandwiched heatsink can hold 150 watts of heat easy....in my environment this one without fans will dissipate 30 watts more or less... take a look, a 75 RMS power amplifier can have this size.... glue the small board into the heat sink, two small microprocessor fans, and a outside tube... excluding supply, and somepeople can make supply smaller than that (EVA and many others), you can have less material, less weigth, and please, forgive me you all friends..... those insulators....i am sorry, but a hell with them!...no need this thermical resistance.... put transistor directly in heatsink!.... small conical automatic screw... the one that will make his rails.... and ready to put power on it!

Isolate the plus side related the minus side with wood, and also this tunnel sink related the metal or wooden or plastic chassis you have.... simple, cheaper, smaller.

I am sure, if not happen already... tomorrow you will not laugh from Destroyer...i am sure about that.

regards you all hahahahahaha...... i will be the last to make that.... and this is the best moment....huhuhu...hohohô!

Carlos

Attachments

Yes its always good to sand the bottom of heatsinks and the bottom of the chips.

Takes maybe 10 minutes and usually makes a noticable improvement in temperature.

I just go with 600 grit, I guess higher would be better. Done on a very flat surface (glass is best, or just any countertop).

Takes maybe 10 minutes and usually makes a noticable improvement in temperature.

I just go with 600 grit, I guess higher would be better. Done on a very flat surface (glass is best, or just any countertop).

Yes, happy to meet same ideas North America too

Because everybody loves "virgin" components, some friends turn nervous when see me sanding components....heatsinks too!...i put squared target with thick adhesive tape, and i sand the middle not covered with tape.... i have also something called here "bit", it is a small part of machinery, can loose to diamond and loose to Vydia in resistance, but is the piece of hard metal people use to cut metals in big machines to mechanics rectification of automobiles engines.... this one i have is flat and one inch...i use it to guarantee flat surface on heatsink... also, do not use insulators,... direct metal to metal, only a heat compound to complete metal microscopic failures.

The world is going fast to reduce costs and size again.... some cars are using plastic and having very good aerodinamics... some of them goes 18 kilometers with one gazoline litter, also those giant aluminium heatsinks will be reduced and increase someway... i think will be fan blowers together with the removal of insulators.... chips will became big, because too small and coupling from input to output, this "forces" to use big condensers to avoid oscilations and is reducing performance our days... they will change size i imagine.

Thank you to comment, this way to do the things, since 1970 or earlier made me lonely... go to see someone doing some alike...you use to sand.....that is fine, we know the improvements.

regards,

Carlos

Because everybody loves "virgin" components, some friends turn nervous when see me sanding components....heatsinks too!...i put squared target with thick adhesive tape, and i sand the middle not covered with tape.... i have also something called here "bit", it is a small part of machinery, can loose to diamond and loose to Vydia in resistance, but is the piece of hard metal people use to cut metals in big machines to mechanics rectification of automobiles engines.... this one i have is flat and one inch...i use it to guarantee flat surface on heatsink... also, do not use insulators,... direct metal to metal, only a heat compound to complete metal microscopic failures.

The world is going fast to reduce costs and size again.... some cars are using plastic and having very good aerodinamics... some of them goes 18 kilometers with one gazoline litter, also those giant aluminium heatsinks will be reduced and increase someway... i think will be fan blowers together with the removal of insulators.... chips will became big, because too small and coupling from input to output, this "forces" to use big condensers to avoid oscilations and is reducing performance our days... they will change size i imagine.

Thank you to comment, this way to do the things, since 1970 or earlier made me lonely... go to see someone doing some alike...you use to sand.....that is fine, we know the improvements.

regards,

Carlos

Sanding is used quite a lot in the PC overclocking community to ensure a better mating between CPU and heatsink (where it is possible to get such a high heat density that an un-sinked processor can burst into flames in less than a second!

BTW, sometimes (when I'm in a good mood) reading Carlos' posts is like stepping into another world... I could almost believe the stream-of-consiousness and bizarre grammar/spelling are done on purpose for entertainment value! 😀

Other times, I haven't got a clue what the posts are about and just skip over them

keep it up, DestroyerX, you're bringing a bit of southern sunshine to the dull UK...

Arnie

BTW, sometimes (when I'm in a good mood) reading Carlos' posts is like stepping into another world... I could almost believe the stream-of-consiousness and bizarre grammar/spelling are done on purpose for entertainment value! 😀

Other times, I haven't got a clue what the posts are about and just skip over them

keep it up, DestroyerX, you're bringing a bit of southern sunshine to the dull UK...

Arnie

I feel good to refresh some people brain

That is very good.

But, do not talk anybody, scchhhhhh!..... our secret..... i am a little bit crazy! ahahahahaha!

This way i wrote crazy things!

Take a look in speaker distortions to make a travell to see Valhala and use the Thor hammer...... the damn thing is that i believe in my wonderings.....and when i decided to cut my hairs....hummmmmm i could see some connections with Napoleon Bonaparte.......hummmmmm , maybe i am..... schhhhhhh! do not talk anybody!

regards,

Carlos

That is very good.

But, do not talk anybody, scchhhhhh!..... our secret..... i am a little bit crazy! ahahahahaha!

This way i wrote crazy things!

Take a look in speaker distortions to make a travell to see Valhala and use the Thor hammer...... the damn thing is that i believe in my wonderings.....and when i decided to cut my hairs....hummmmmm i could see some connections with Napoleon Bonaparte.......hummmmmm , maybe i am..... schhhhhhh! do not talk anybody!

regards,

Carlos

Attachments

Hi Carlos;

Due to language barrier I also sometimes have trouble following your posts but I do enjoy them. 😀

So is your device here a forced air cooling plenum made by two heatsinks sandwiched inside of particle board? Are you attaching a fan right to the plenum? I like the idea as long as a remote blower connection is an option to totally eliminate fan noise.

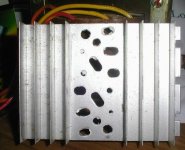

You mention mounting devices right to the heatsink. I have been considering doing this on an amp that I have prototyped and then insulating the heatsink from the chassis. I might use a wood mounting block or a thin rubber insulating pad. If I use the rubber I would have to insulate the mounting bolts or use non-metalic hardware. With a wood block I could connect it to the chassis with regular wood screws (and glue) and do the same to attach the sink to the wood. The heatsink is the old fashioned bolt on type like this.

Due to language barrier I also sometimes have trouble following your posts but I do enjoy them. 😀

So is your device here a forced air cooling plenum made by two heatsinks sandwiched inside of particle board? Are you attaching a fan right to the plenum? I like the idea as long as a remote blower connection is an option to totally eliminate fan noise.

You mention mounting devices right to the heatsink. I have been considering doing this on an amp that I have prototyped and then insulating the heatsink from the chassis. I might use a wood mounting block or a thin rubber insulating pad. If I use the rubber I would have to insulate the mounting bolts or use non-metalic hardware. With a wood block I could connect it to the chassis with regular wood screws (and glue) and do the same to attach the sink to the wood. The heatsink is the old fashioned bolt on type like this.

Attachments

Yeah! Manshaffer, that's the idea!

The wind goes along the fins, longitudinal, along them.... of course noise will happen when reaching 90 degrees angles...must sand them, making them rounded.

Is wonderfull...i am using..... hard 140 watts amplifier pumping damn sound....neighboors happy as they always dream! hahahaha!

And cannot feel heat in the sink!!!!....opening the tunnel and both sides using fan...one pulling other pushing....no heat!

That's very good, and cheap, those small blowers from old PC are going to trash!

Can use silicone.... absorb vibration too...good to mount... and finishment is rounded!

Carlos

The wind goes along the fins, longitudinal, along them.... of course noise will happen when reaching 90 degrees angles...must sand them, making them rounded.

Is wonderfull...i am using..... hard 140 watts amplifier pumping damn sound....neighboors happy as they always dream! hahahaha!

And cannot feel heat in the sink!!!!....opening the tunnel and both sides using fan...one pulling other pushing....no heat!

That's very good, and cheap, those small blowers from old PC are going to trash!

Can use silicone.... absorb vibration too...good to mount... and finishment is rounded!

Carlos

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Heatsink, the next step into near future