Hi guys,

the force cancelling configuration has the great benefit of cleaning the sound thanks to the cancellation of the backwave, which doesn't reflect and hit again the cone.

My great doubt is:

how up in frequency is the solution viable? Because the dispersion at 90 degrees of the woofer/midwoofer must be taken into account...

Do you think that 2 lateral 7" drivers (Sd 160cm2) could be used up to 700hz in such a configuration?

The loudspeaker would be a 3-way, a sort of sphere, with a small upper-midrange and a ribbon or AMT from 4,5 Khz.

Is there already some beaming of the woofers at 90 degrees? (In the direction of the listener)

the force cancelling configuration has the great benefit of cleaning the sound thanks to the cancellation of the backwave, which doesn't reflect and hit again the cone.

My great doubt is:

how up in frequency is the solution viable? Because the dispersion at 90 degrees of the woofer/midwoofer must be taken into account...

Do you think that 2 lateral 7" drivers (Sd 160cm2) could be used up to 700hz in such a configuration?

The loudspeaker would be a 3-way, a sort of sphere, with a small upper-midrange and a ribbon or AMT from 4,5 Khz.

Is there already some beaming of the woofers at 90 degrees? (In the direction of the listener)

For the most coherent multi-driver sound, all drivers should be within one quarter wavelength distance.

700Hz = 4.8" quarter wavelength

So, counter-force drivers are only used on woofers.

A tapered transmission line with clever stuffing is sometimes used to smooth and absorb the rear wave of a midrange. Since a midrange often has 10g - 20g of moving mass, a heavy cabinet provides adequate stability.

700Hz = 4.8" quarter wavelength

So, counter-force drivers are only used on woofers.

A tapered transmission line with clever stuffing is sometimes used to smooth and absorb the rear wave of a midrange. Since a midrange often has 10g - 20g of moving mass, a heavy cabinet provides adequate stability.

Attachments

benefit of cleaning the sound thanks to the cancellation of the backwave, which doesn't reflect and hit again the cone.

That is not how it works. Backwave is not canceled — force cancelling woofers are acoustically in phase, mechanically out of phase — it can actual exacerbate things (but usually XOed lower than where this would be an issue). Mechanical reaction forces in the woofers are activly canceled and you get much less vibration passed into the cabinet greatly reducing the box load.

We have built a number of systems with push-push woofers, but have not crossed as high as 700 Hz. When our passive XO guy did an XO for out latest effort, Tysen V2, he XOed at what i thot was a surprisingly high 450 Hz. When we did active we had the XO at 240 Hz. He base his work on lots of measurements, i guess the 5” woofers have very good off-axis performance.

(now veneered, need to take more pictures)

dave

I think a lot of us still think that the big problem is acoustic pressure in the enclosure. It now looks like it is a mechanical problem, that the vibrating mass of the LF driver is being transmitted to the box and exciting panel resonances. How does that happen? Via the motor itself, as far as I can tell. So energy flows two ways at once. Unfair!

Newton's 3rd law, "to every action is an equal and opposite reaction". Force cancelling works incredibly well at low frequencies. My subwoofer build used two opposed Peerless 12" XLS 830500 in a sealed enclosure. When connected in phase there was no detectable box vibration when pushing 15 Hz at insane levels into the sub. I did not measure the SPL's but it was excessive. We later found that the plaster-board screws had popped in a few places in the room! I did the saucer of water balance test on the sub and was unable to generate a ripple. At higher frequencies, I would expect that it is much more difficult to get the reaction forces of the opposed drivers to be exactly equal due to component spec spread, especially if using a passive XO. The sub was used with an active XO.... vibrating mass of the LF driver is being transmitted to the box and exciting panel resonances. How does that happen? Via the motor itself, as far as I can tell. So energy flows two ways at once. Unfair!

Attachments

Circular PVC tube?

I could get the top of my SDX10 push-push subs to vibrate (at insane levels too) but that was a 15mm rectangular box.

My post #5 Force Cancellation: X, Y or Z axis? has pictures and more narrative.

dave

I could get the top of my SDX10 push-push subs to vibrate (at insane levels too) but that was a 15mm rectangular box.

My post #5 Force Cancellation: X, Y or Z axis? has pictures and more narrative.

dave

Circular PVC tube?

Yes, 40 cm diameter, approx 8mm wall thickness. I usually go to extremes with bracing and CLD. I must admit I was skeptical that PVC pipe would be up to the job, but my misgivings were without foundation. Similarly to spherical enclosures, cylinders are very resistant to ballooning from internal pressures due to the symmetrical distribution of air pressure. The only bracing is an internal mid-way 50mm thick mdf disc which bisects the sealed enclosure. Since the air pressure are equal on both sides, the disc is force balanced. The 5mm threaded rods connects through each of the woofer flange holes. Tensioning is not critical to the performance. Placing a hand on the cylinder I cannot feel any vibration.

Yes, a tube is an inherently stable “box” i have PVC cut, and 8 woofers to do a push-push push-pull woofer. I was going to put a brace inside that has the primary purposes of coupling the magnets of the push-pull pairs.

dave

dave

I have always had an issue with coupling the magnets. If an objective is to minimise or eliminate the driver vibrations that are coupled to the box and then can potentially be re-radiated in unpredictable/undesirable ways, this is surely better done by force cancelling applied right where the driver mates with the box. That is, at the driver flange. In principle the magnets could be connected in force cancelling but there is still a residual vibration in the driver flange that can be transmitted to the box. Just my 2c worth.I was going to put a brace inside that has the primary purposes of coupling the magnets of the push-pull pairs.

dave

For the most coherent multi-driver sound, all drivers should be within one quarter wavelength distance.

700Hz = 4.8" quarter wavelength

So, counter-force drivers are only used on woofers.

A tapered transmission line with clever stuffing is sometimes used to smooth and absorb the rear wave of a midrange. Since a midrange often has 10g - 20g of moving mass, a heavy cabinet provides adequate stability.

Thanks! So actually I have an even bigger problem than the dispersion at wide angles...

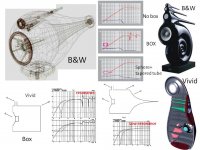

The idea of the nautilus is great, but expensive to build... The truth is that I heard the bass of a dipole, so no box at all... I have reason for abandoning the dipole, but its cleanness, once you heard it, gets you really picky about bass...

He base his work on lots of measurements, i guess the 5” woofers have very good off-axis performance.

Thanks to you too, but actually the center of the midwoofers would be farther away than 4,8" from the midrange. I guess that some weird lobing may happen...

I will consider a "normal" 3 way and I will have to study well the enclosure for the woofer (the high-mid is sealed so no problem at all, it's the new Accuton C51).

... I heard the bass of a dipole, so no box at all... I have reason for abandoning the dipole, but its cleanness, once you heard it, gets you really picky about bass...

My experience — granted limited to Alpha 15 in OB and H-frame, was dominated by the issues with the driver. Certainly not clean.

dave

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Force cancelling mid-woofer, possible?