Hey guys,

I'd like to lay down my preliminary plans for a "force cancelling PA sub" and get your feedback on my implementation this concept.

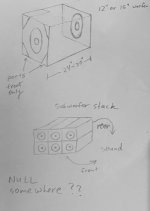

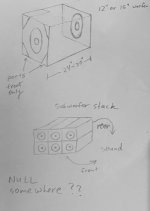

It is sort of like placing a pair of ported cabinets back-to-back, with a total depth of 24 to 30 inches.

The concept is simple but has a potential problem (and I don't know if it is a problem) so I would love to hear your thoughts.

First, I will list my "wants":

Scalable, so one or more cabinets, depending on the application: outdoors, or indoor venue such as a bar or a club.

A pair of 12" or 15" drivers per cabinet, one on the front and one on the back.

Ports on the front only

Simple to build in multiples

Mobile cabinet and not too big and heavy

Cabinet depth of 24" to 30", stackable for use in multiples

Needed bandwidth of 30-150hz

Why force cancelling? The reason is many venues are built in such a way that the vibrations from subwoofers are transfers to the building structure. It is problem for DJs and vinyl playback as well as causing the entire venue to vibrate. The goal is to minimize this problem to not have to fix it down the road.

What is the potential problem? Well, here is where this concept may hit a dead end. The issue of the front woofer to back woofer offset that is tied on the depth of the subwoofer, 24" to 30" inches. It will cause a delay between woofers from the listener location. There will probably be a NULL in the freq response but where? What kind of irregularities can I expect in the radiation pattern around the sub? What happens when I use multiples, lets say a stack of 3x3 -- now the distance from front to back woofer is greater than that of single box. Will this create a NULL in the front and rear radiation pattern?

Is it a cardioid type of a NULL?

Most certainly there will be a NULL somewhere, tied to the offset of drivers, but where? Will it be audible in a room? Outside?

This sketch is based on above criteria:

thanks!

I'd like to lay down my preliminary plans for a "force cancelling PA sub" and get your feedback on my implementation this concept.

It is sort of like placing a pair of ported cabinets back-to-back, with a total depth of 24 to 30 inches.

The concept is simple but has a potential problem (and I don't know if it is a problem) so I would love to hear your thoughts.

First, I will list my "wants":

Scalable, so one or more cabinets, depending on the application: outdoors, or indoor venue such as a bar or a club.

A pair of 12" or 15" drivers per cabinet, one on the front and one on the back.

Ports on the front only

Simple to build in multiples

Mobile cabinet and not too big and heavy

Cabinet depth of 24" to 30", stackable for use in multiples

Needed bandwidth of 30-150hz

Why force cancelling? The reason is many venues are built in such a way that the vibrations from subwoofers are transfers to the building structure. It is problem for DJs and vinyl playback as well as causing the entire venue to vibrate. The goal is to minimize this problem to not have to fix it down the road.

What is the potential problem? Well, here is where this concept may hit a dead end. The issue of the front woofer to back woofer offset that is tied on the depth of the subwoofer, 24" to 30" inches. It will cause a delay between woofers from the listener location. There will probably be a NULL in the freq response but where? What kind of irregularities can I expect in the radiation pattern around the sub? What happens when I use multiples, lets say a stack of 3x3 -- now the distance from front to back woofer is greater than that of single box. Will this create a NULL in the front and rear radiation pattern?

Is it a cardioid type of a NULL?

Most certainly there will be a NULL somewhere, tied to the offset of drivers, but where? Will it be audible in a room? Outside?

This sketch is based on above criteria:

thanks!

The pattern would not be cardioid in your proposed array configuration.

There are multiple path lengths between the front and rear drivers direct and reflected output in any direction, which will cause a series of peaks and dips, known as comb filtering. The upper response will suffer the most, as a full wavelength of 150Hz is 7.5 feet long, ideally you would want no more than 1/4 wavelength (22.6 inch) path length difference at any given listening point to avoid peaky response.

Push-pull or push-push designs largely eliminate the path length distance problem at sub frequencies, while still providing force cancelling, and some additional upper response gain:

Mounting the drivers opposite each other in a plenum (slot) in either push-push or push-pull (opposite direction with the polarity of the "backwards" driver reversed) would have much more consistent indoor or outdoor frequency response than your proposed driver configuration.

There are multiple path lengths between the front and rear drivers direct and reflected output in any direction, which will cause a series of peaks and dips, known as comb filtering. The upper response will suffer the most, as a full wavelength of 150Hz is 7.5 feet long, ideally you would want no more than 1/4 wavelength (22.6 inch) path length difference at any given listening point to avoid peaky response.

Push-pull or push-push designs largely eliminate the path length distance problem at sub frequencies, while still providing force cancelling, and some additional upper response gain:

Mounting the drivers opposite each other in a plenum (slot) in either push-push or push-pull (opposite direction with the polarity of the "backwards" driver reversed) would have much more consistent indoor or outdoor frequency response than your proposed driver configuration.

Last edited:

Surely you need to be using electronics to equalise the speakers. You can then adjust the levels and cut off frequency to suit the venue.

No sub design is going to work in all venues and of course the biggest factors are outside of your control - the internal dimensions and the placement of the subs in this space.

The Linkwitz-Riley Transform circuit is often used to compensate for LF roll off of subs so there is little need to design complex enclosures which have their own disadvantages as you have realised.

No sub design is going to work in all venues and of course the biggest factors are outside of your control - the internal dimensions and the placement of the subs in this space.

The Linkwitz-Riley Transform circuit is often used to compensate for LF roll off of subs so there is little need to design complex enclosures which have their own disadvantages as you have realised.

...

Most certainly there will be a NULL somewhere, tied to the offset of drivers, but where? Will it be audible in a room? Outside?

...

Hi, the configuration is bipole. Nulls would form where ever direction the sources are 1/2wl apart, or multiple of. The null forms not to side, because the drivers are always equidistant there, but to the main axis, "front off". First null would be when depth of the box is half wavelength. For 30" this would be about 280Hz and for 30" about 220Hz.

Very easy to play with in VituixCAD, open the program, copy the driver, hook it up, adjust Z offset of the other.

Attachments

Last edited:

Otherwise cardioid sub or nested arrangements

are incredible common. using cancelling and delays.

requires using matching drivers.

and delay settings are specific to each venue

subs that rattle a building unavoidable.

the issue is feedback, or a boomy mix from front of house speakers.

for stage performers. its common to see 6 subs lined across the front.

typical nest is 4 forward 2 back. or towers.

I like the tower method personally, but most venues prefer lining the stagefront.

are incredible common. using cancelling and delays.

requires using matching drivers.

and delay settings are specific to each venue

subs that rattle a building unavoidable.

the issue is feedback, or a boomy mix from front of house speakers.

for stage performers. its common to see 6 subs lined across the front.

typical nest is 4 forward 2 back. or towers.

I like the tower method personally, but most venues prefer lining the stagefront.

This configuration will have greater efficiency of force cancelation, and raise the cavity resonance a bit, than the ones weltersys showed. If the woofers are cheap the configuration that is also push-pull may be an improvement.

dave

dave

Main source of vibration is air-borne by the immense force of acoustic waves of big subs. Structural-borne vibrations are easily suppressed by mounting rubber feet beneath the subs, so no need for force-cancelation sub design.Why force cancelling? The reason is many venues are built in such a way that the vibrations from subwoofers are transfers to the building structure. It is problem for DJs and vinyl playback as well as causing the entire venue to vibrate. The goal is to minimize this problem to not have to fix it down the road.

Not quite. It's a similar issue as with rocking modes with engines, and using multiple cylinders and various counter-weights to help fix it. Even with rubber feet, the subs will rotate back and forth, producing up-down forces on the floor even if the driver is mounted forward-firing. Maybe precision bearings would do the trick, but then use them, not rubber feet.

Engines (compensated for vibrations or not) are mounted on the floor with conventional spring/rubber feet - it is the accepted standard.

There are countless venues packed with multiple subs of non-force-cancelation design, or without special precision bearings - just plain rubber montage feet. Structure-borne sub vibrations are non-issue in concert venues.

There are countless venues packed with multiple subs of non-force-cancelation design, or without special precision bearings - just plain rubber montage feet. Structure-borne sub vibrations are non-issue in concert venues.

Force cancelation is useful to reduce vibration: mainly to reduce/mitigate box related issue ( vibration of box panels).

It is very effective to reduce box rocking too ( box walking).

Use of rubber feet (or other system) in order to decouple the box from the room ( structral born/transmited vibration) is effective IF it is calculated and using dedicated products ( read not cheap as dirt, can be cheaper if 'industrial' products rather than audio dedicated ones ).

But, even if decoupled it might not help with airborn transmission as Sonce pointed.

Usually when setting up sound system we used to decouple the desks first: there was kind of orange inflating bag to put under the technics which were effective at decoupling ( iirc something in the 1/2hz range). Rubber will give much higher fc so might be less efficient...

Decoupling the sub can have a 'too clean' sound for party. You should try before doing it to a whole system imho.

It is very effective to reduce box rocking too ( box walking).

Use of rubber feet (or other system) in order to decouple the box from the room ( structral born/transmited vibration) is effective IF it is calculated and using dedicated products ( read not cheap as dirt, can be cheaper if 'industrial' products rather than audio dedicated ones ).

But, even if decoupled it might not help with airborn transmission as Sonce pointed.

Usually when setting up sound system we used to decouple the desks first: there was kind of orange inflating bag to put under the technics which were effective at decoupling ( iirc something in the 1/2hz range). Rubber will give much higher fc so might be less efficient...

Decoupling the sub can have a 'too clean' sound for party. You should try before doing it to a whole system imho.

Last edited:

Main source of vibration is air-borne by the immense force of acoustic waves of big subs.

While it becomes much more significant at really low frequencies, it is still very easy to show that the majority of vibrations are transfered mechanically. Push-psuh reaction cancelation largelty actively cancels the soyrce of those, then leaving air space issues as dominant.

The rubber feet comment strikes me as a joke.

dave

Lots of info on PPSL = Push Pull Slot Loaded in this old thread.

https://www.diyaudio.com/community/threads/a-thread-for-those-interested-in-ppsl-enclosures.177905/

https://www.diyaudio.com/community/threads/a-thread-for-those-interested-in-ppsl-enclosures.177905/

True.... using dedicated products ( read not cheap as dirt, can be cheaper if 'industrial' products rather than audio dedicated ones ).

Then, RCF engineers (and all others) must be first-rate jokers!? Pay attention to the four small round rubber feet/discs at the corners (both at bottom and at side) of the RCF SUB 9004:The rubber feet comment strikes me as a joke.

Have you ever seen a professional sound reinforcement subwoofer before?

Last edited:

Or any Genelec monitors...

https://www.genelec.com/smart-active-2-way-studio-monitors

But this is peanuts compared to the real deal: seismic isolation( take a look at first picture, Utah State Capitol).

https://en.m.wikipedia.org/wiki/Seismic_base_isolation

The real issue with rubber ( or variant) for audio is related to weight: were a building weight enable decoupling to very low frequency even very heavy loudspeakers doesn't allow for sub 10hz decoupling easily. Air based isolators allow for sub 1hz easily but aren't this easy to implement.

That's why you'll often see spring used too in serious decoupling structure for audio.

See at 50 second and 2minutes.

When less budget is allowed we use this ( in high number) under slab:

http://www.akustar.com/tech/146_i_pads.htm

https://www.genelec.com/smart-active-2-way-studio-monitors

But this is peanuts compared to the real deal: seismic isolation( take a look at first picture, Utah State Capitol).

https://en.m.wikipedia.org/wiki/Seismic_base_isolation

The real issue with rubber ( or variant) for audio is related to weight: were a building weight enable decoupling to very low frequency even very heavy loudspeakers doesn't allow for sub 10hz decoupling easily. Air based isolators allow for sub 1hz easily but aren't this easy to implement.

That's why you'll often see spring used too in serious decoupling structure for audio.

See at 50 second and 2minutes.

When less budget is allowed we use this ( in high number) under slab:

http://www.akustar.com/tech/146_i_pads.htm

Last edited:

Have you ever seen a professional sound reinforcement subwoofer before?

I have made them. Feet are needed to ensure they don’t slip around. Think about the size of the foor required to isolate a mass that large from what it sits on.

dave

I am making them too. Above 800 units to date.

For every feet there is a complementary round hole on the other side of the enclosure - to ensure subs don't slip around when stacked on a top of each other. So feet do not need to be made from rubber, to ensure non-slipping.

Feet are made from rubber - not from another material. Guess why.

For every feet there is a complementary round hole on the other side of the enclosure - to ensure subs don't slip around when stacked on a top of each other. So feet do not need to be made from rubber, to ensure non-slipping.

Feet are made from rubber - not from another material. Guess why.

Rubber feet do suppress vibration - heavy industry machines make much more powerful vibrations than subwoofers. Here are some examples for vibration damping rubber feet:

https://www.vibrationmountsindia.com/compressor-machine-vibration-mounts/

https://www.vibrationmountsindia.com/injection-moulding-machine-vibration-mounts/

https://www.vibrationmountsindia.com/compressor-machine-vibration-mounts/

https://www.vibrationmountsindia.com/injection-moulding-machine-vibration-mounts/

Are the ones on the speaker more than rubber bumps? Yje ones on the machines are purpose desogned shock absorbers, not rubber feet.

dave

dave

- Home

- Loudspeakers

- Subwoofers

- Flaw of a force canceling 12" or 15" PA sub design?