Hello all you fine HiFi afficinados.

After success with first ever DIY turntable, and followed by a total restauration of a RIAA, i decided to plunge in, and try to do my own tonearm. I mean - how hard can it be ;-]

Well, not so easy afterall. Been on the project for ages, and discarded a few muckups/ideas too, but now im happy with the current status. A lotta questions still remains though, and i am calling upon your help :-]

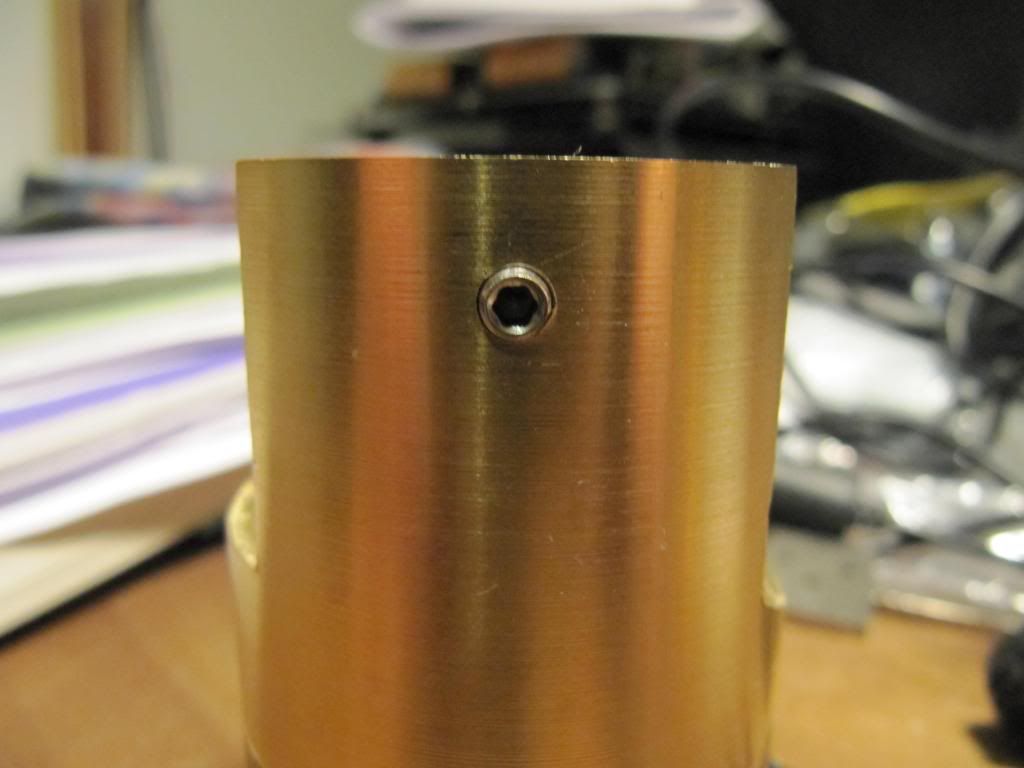

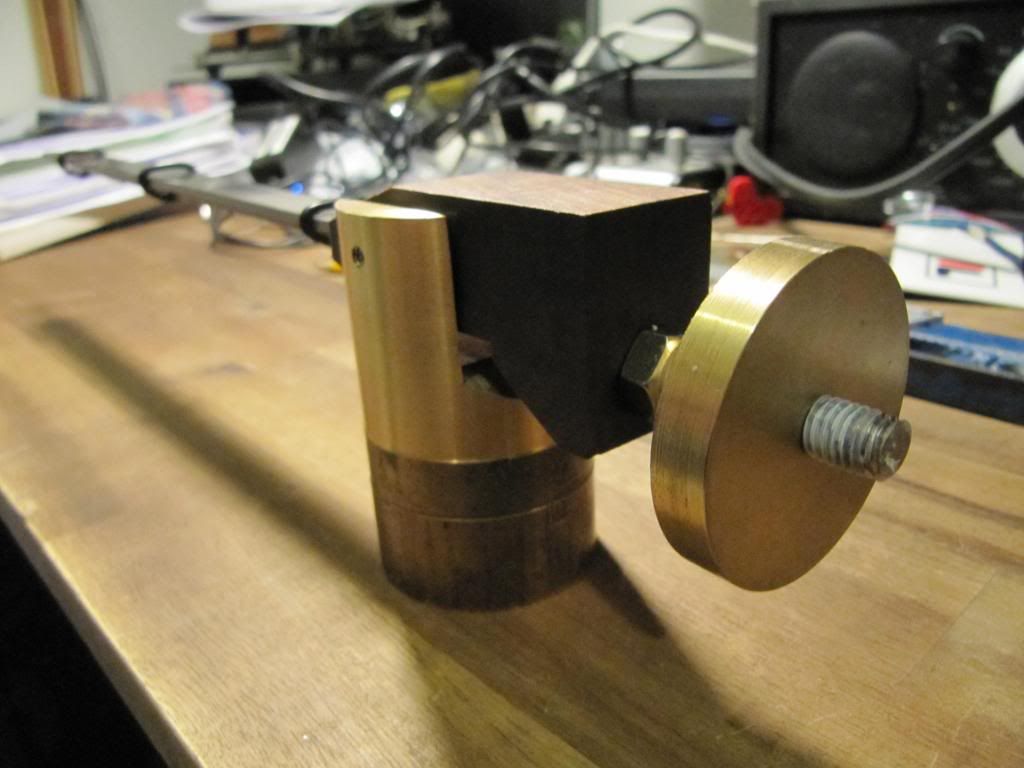

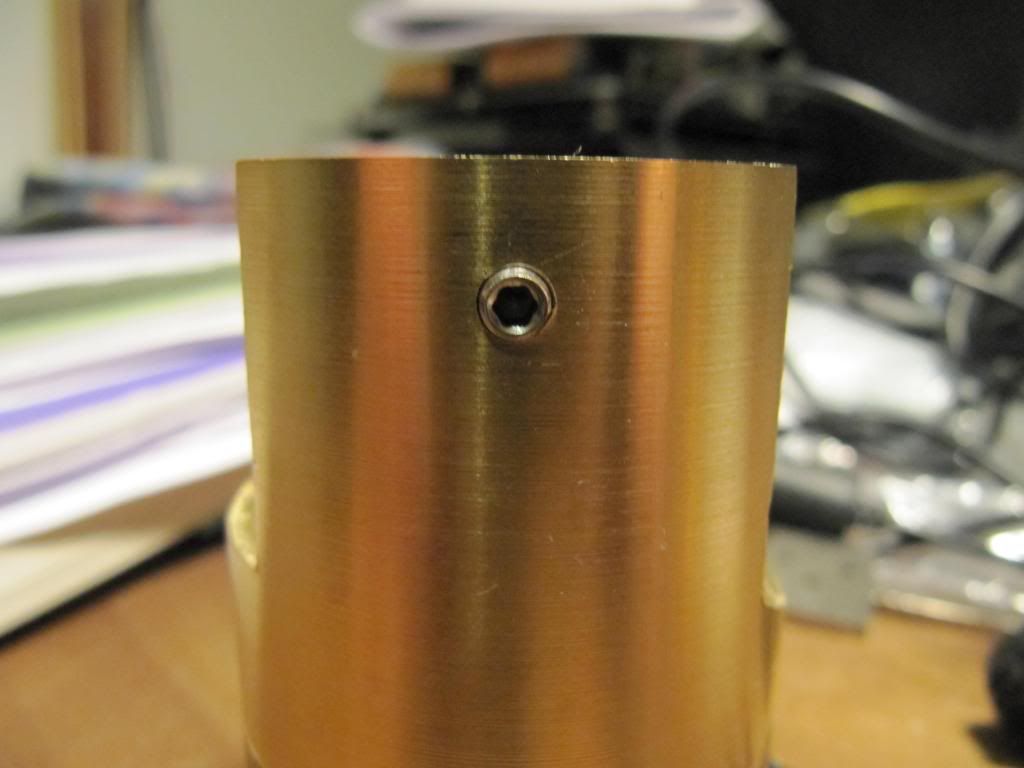

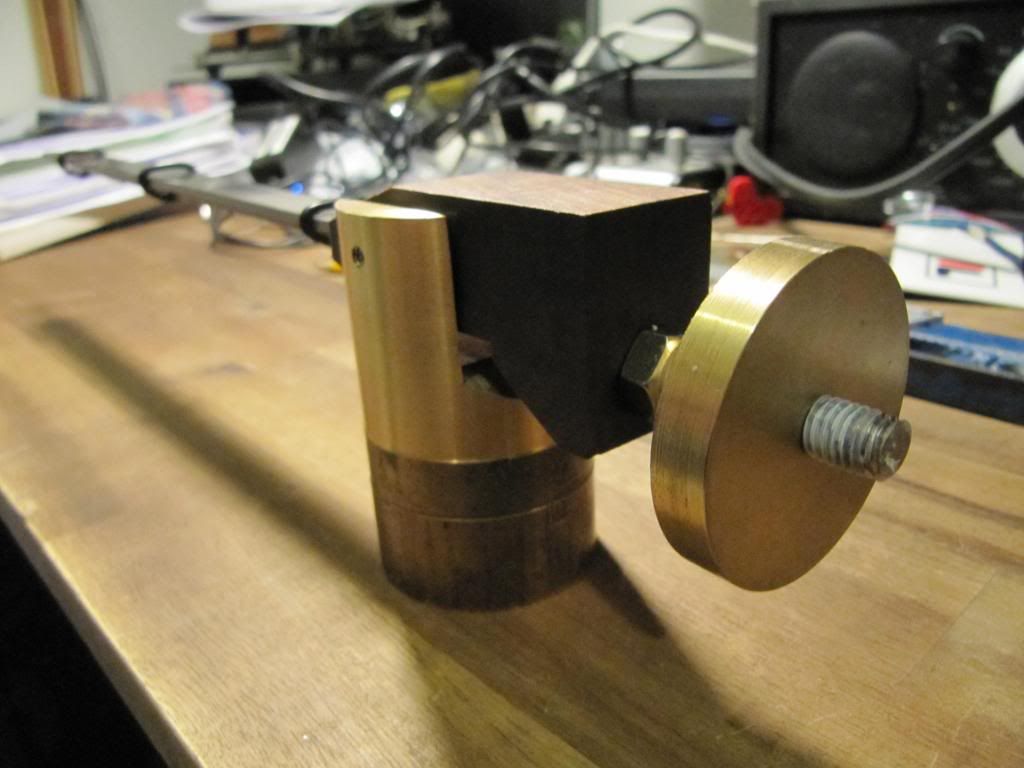

First things first, heres some pictures of current progress:

Still a lotta work, but im getting there :-] Need to figure out the horisontal bearing, and how to attach the carbon tube, to the titanium arm.

Now the question in spe: Does anyone here knows a way to bond carbon tube to titanium?? Ive tried 5 different types of gluing agent, and none worked so far - thous the ugly rubber rings attached now :-[

After success with first ever DIY turntable, and followed by a total restauration of a RIAA, i decided to plunge in, and try to do my own tonearm. I mean - how hard can it be ;-]

Well, not so easy afterall. Been on the project for ages, and discarded a few muckups/ideas too, but now im happy with the current status. A lotta questions still remains though, and i am calling upon your help :-]

First things first, heres some pictures of current progress:

Still a lotta work, but im getting there :-] Need to figure out the horisontal bearing, and how to attach the carbon tube, to the titanium arm.

Now the question in spe: Does anyone here knows a way to bond carbon tube to titanium?? Ive tried 5 different types of gluing agent, and none worked so far - thous the ugly rubber rings attached now :-[

You can check out Loctite adhesives for epoxy that may work. However, I think you may find it easier to use just a larger diameter aluminum / carbon fiber tube as your arm wand

as it will save you some unnecessary grief. If excellent arm performance is your goal, then I would suggest giving the DIY linear tonearm design a try if you have room on your turntable. Good luck in your build.

Tonearm design is MUCH more difficult then it looks

as it will save you some unnecessary grief. If excellent arm performance is your goal, then I would suggest giving the DIY linear tonearm design a try if you have room on your turntable. Good luck in your build.

Tonearm design is MUCH more difficult then it looks

Looks nice! How did you do the brass (?) machining? And I thought machining titanium was very difficult.

Thnx for replies ;-) I have allready tried different epoxies, and none would bind to the titanium. Next project is going to be a unipivot style, from a single tube of carbon.

Just thought it would be fun to do something in titanium (witch is tricky to machine) and it looks different from the millions of tonearms done with tubular wands. I have done the brass On a lathe / mill - and as weekend speak, im drawing the vta mechanism.

Im allso considering keeping the black rubber o-rings - Think it might help damping vibrations??

Just thought it would be fun to do something in titanium (witch is tricky to machine) and it looks different from the millions of tonearms done with tubular wands. I have done the brass On a lathe / mill - and as weekend speak, im drawing the vta mechanism.

Im allso considering keeping the black rubber o-rings - Think it might help damping vibrations??

Hi,

There is a very good reason for tubular, its vastly superior

to a solid section compared to weight in all respects.

The inevitable consequence of using a flat section.

will be a very low vertical break frequency, the

carbon tube won't help much and the two

together seem a perverse approach.

The horizontal bearing could be the simple AR-XA style,

perhaps inverted, with a pin into the brass housing.

rgds, sreten.

There is a very good reason for tubular, its vastly superior

to a solid section compared to weight in all respects.

The inevitable consequence of using a flat section.

will be a very low vertical break frequency, the

carbon tube won't help much and the two

together seem a perverse approach.

The horizontal bearing could be the simple AR-XA style,

perhaps inverted, with a pin into the brass housing.

rgds, sreten.

Lots of carefull workmanship indeed.

Initial first impression was: my Gawd It's Massive. Which can't be ideal.

Do a search for Nanooks' 2.19$ diy arm.

Initial first impression was: my Gawd It's Massive. Which can't be ideal.

Do a search for Nanooks' 2.19$ diy arm.

Regarding weight, the titanium rod,dosent weight much - and the carbon tube, is solemnly for the headshell wires ;-)

🙂 Allways good to hear different opinions regarding the lovely DIY universe :-] I do it this way, simply cause Its fun. The titanium wand only weighs some 2 grams more than a standard technics s-shaped wand.

As im a noob in this field, i gotta ask, why carbon is better than titanium, and why a tube is better?? The dynavector, as i understand, is a fine tonearm - isnt it??

When i finish the next project (carbon, lightweight and allso 12") ill be able to do a direct comparison between the two. And isnt DIY, all about trying different approaches??

As im a noob in this field, i gotta ask, why carbon is better than titanium, and why a tube is better?? The dynavector, as i understand, is a fine tonearm - isnt it??

When i finish the next project (carbon, lightweight and allso 12") ill be able to do a direct comparison between the two. And isnt DIY, all about trying different approaches??

A hollow cylinder follows form and function.

I suggest to keep the wires outside the arm. Don't need any shielding as long

the environment is EMI free. Directly attaching them to the prephono RCAs

reduces the probability of catching "hum", as well as reducing deciBel losses

I suggest to keep the wires outside the arm. Don't need any shielding as long

the environment is EMI free. Directly attaching them to the prephono RCAs

reduces the probability of catching "hum", as well as reducing deciBel losses

Please elaborate for me? Remember i am a noob 😀A hollow cylinder follows form and function

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- First ever DIY tonearm