Hey there fellow DIYers. Starting this thread for a speaker build I am starting it will use a 10" 10fe300 faitalpro woofer with a faitalpro HF108 compression driver fitted with sth100 horn. I am designing this as a sealed design since this will be used for home theater not worried about it going low since I'll be using 2 marty cubes to handle the low end. It was difficult to find a 10" pro driver to go low enough in a sealed design thats why I went with the 10fe300. For now they'll be used for home theater and 2 channel music. I figured I would start this thread to share my experience on my first diy speaker build so I'm open to pointers/help and I'll answer any questions you might have for me. Will add more pics and info as I go through each process forgot to take pics of just the 2 drivers and horn guess I was too excited to get the project going 🙂.

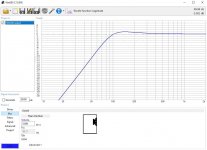

Here's the final look of the box and the flat pack laid out used a panel saw to cut the dimensions then cnc at work to cut the front baffle. Here is the driver modeled in WinISD got about a 1 db hump at 150hz I was trying to stay within a certain sized box so didn't want stray away from those dimensions too much. Overall it should dig deep enough to hand off to my subs.

Here's the front baffle all cut out came out really nice fits the drivers and horn perfectly🙂. The final box built some of my panel saw cuts weren't exact so I've got some sanding and patch work on some edges to do oh well for now I'm more worried about how its going to sound.

First measurements in room so I used gated response in REW at about 4.5ms. Took each driver response separately then wired them in parallel to get a combined response so I could figure out the z offset when using Xsim. I have already designed the xover and ordered the parts from parts express should be coming in this weekend 🤞. Xover point is right at 1.6k should be a good starting off point. Not totally sure on how the xover design is going to sound this is the part I have a feeling will be the most work and require lots of learning.

That's where I'm at in this process I am excited to hear it all come together. If any of yall have tips or just want to exchange info about speaker builds feel free to reach out.

Thanks.

Jeff

Here's the final look of the box and the flat pack laid out used a panel saw to cut the dimensions then cnc at work to cut the front baffle. Here is the driver modeled in WinISD got about a 1 db hump at 150hz I was trying to stay within a certain sized box so didn't want stray away from those dimensions too much. Overall it should dig deep enough to hand off to my subs.

Here's the front baffle all cut out came out really nice fits the drivers and horn perfectly🙂. The final box built some of my panel saw cuts weren't exact so I've got some sanding and patch work on some edges to do oh well for now I'm more worried about how its going to sound.

First measurements in room so I used gated response in REW at about 4.5ms. Took each driver response separately then wired them in parallel to get a combined response so I could figure out the z offset when using Xsim. I have already designed the xover and ordered the parts from parts express should be coming in this weekend 🤞. Xover point is right at 1.6k should be a good starting off point. Not totally sure on how the xover design is going to sound this is the part I have a feeling will be the most work and require lots of learning.

That's where I'm at in this process I am excited to hear it all come together. If any of yall have tips or just want to exchange info about speaker builds feel free to reach out.

Thanks.

Jeff

Attachments

Last edited:

Nice build!

what model 10 inch driver is that? and how did you cut that elliptical hole for the sth100 horn? is there some kind of cnc program for ellipses and you just put in height and width ?

what model 10 inch driver is that? and how did you cut that elliptical hole for the sth100 horn? is there some kind of cnc program for ellipses and you just put in height and width ?

Hi there, Jeff

Very nice build! I'm curious if you had logged more details on this elsewhere and would appreciate your thoughts on how they ended up sounding and your assessment on the overall design. Was also curious as to what speakers you were using for surrounds/heights. Thank you and appreciate your time.

Very nice build! I'm curious if you had logged more details on this elsewhere and would appreciate your thoughts on how they ended up sounding and your assessment on the overall design. Was also curious as to what speakers you were using for surrounds/heights. Thank you and appreciate your time.

Use a CAD to draw it in 3D.is there some kind of cnc program for ellipses and you just put in height and width ?

Use CAM software to create the toolpaths etc.

Pretty basic in terms of todays CNC tools.