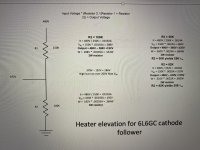

All the parts have come in for the refurbishment of my ShoBud Compactra, including a 6.3 VAC transformer for the 6L6GC cathode follower. The tube has 378 VDC on the cathode - way over the max heater to cathode voltage. Some say just leave the Vhk voltage alone as it has worked fine (as far as I know) for decades. The elevation voltage level would have to be quite high just to get the Vhk barely in spec. 90 VDC is about the highest elevation voltage I have ever heard of. Would almost 200 VDC be too high? My voltage divider math is attached. Thanks

Attachments

First remove the death cap.

You could have even worse problems trying to change the filament elevation,

so maybe it's best to leave well enough alone. But if you do try it, the elevation

divider output does need decoupling.

http://www.prowessamplifiers.com/schematics/misc/Shobud_Compactra_100.html

You could have even worse problems trying to change the filament elevation,

so maybe it's best to leave well enough alone. But if you do try it, the elevation

divider output does need decoupling.

http://www.prowessamplifiers.com/schematics/misc/Shobud_Compactra_100.html

I could not find a rating for the 6L6GC maximum cathode to filament voltage.

The KT66 is 200V

The KT88 is 250V

How many volts does your 6L6GC cathode swing?

It is at 378V DC, right?

If it swings + 150 and - 150V with signal above and below the 378V DC;

That is 378 + 150V = 528V; and 378 - 150V = 228V

If you elevate the 6.3V to 378V DC it will probably work OK for cathode signals of + and - 150V.

Without a bypass cap from the junction of the resistance divider, the elevated filament voltage will tend to follow the cathode voltage;

That might be OK, but there might be hum as a result if there is any filament to cathode leakage.

In any case, you should not use the same 6.3V winding to power other tubes, since their filament to cathode voltage maximum will be exceeded.

I hope that explains the principal of it.

The KT66 is 200V

The KT88 is 250V

How many volts does your 6L6GC cathode swing?

It is at 378V DC, right?

If it swings + 150 and - 150V with signal above and below the 378V DC;

That is 378 + 150V = 528V; and 378 - 150V = 228V

If you elevate the 6.3V to 378V DC it will probably work OK for cathode signals of + and - 150V.

Without a bypass cap from the junction of the resistance divider, the elevated filament voltage will tend to follow the cathode voltage;

That might be OK, but there might be hum as a result if there is any filament to cathode leakage.

In any case, you should not use the same 6.3V winding to power other tubes, since their filament to cathode voltage maximum will be exceeded.

I hope that explains the principal of it.

Thanks for your replies, but I should have explained the use of the 6L6GC clearer. It is only being used to provide "regulated" 378 VDC for the screen grids of two output tubes. It's shown in the schematic that rayma provided a link to above in post 2. My concern is still about using a higher than normal elevated voltage for the heaters. Thanks for the advice regarding a separate transformer for the 6L6, the death cap, and the decoupling/smoothing cap. All have been addressed already.