Mods: I don't *think* this violates any rules but if it does and needs to be removed, please let me know how I can still share this info since I think many here will be interested in it.

Many of you know that I used to do speaker/driver testing for a number of years for DIYMA before moving on to creating my own site (medleysmusings). If you have no idea what that is, it’s a site I used to post objective data to and share with the community. It was focused on providing Klippel data, frequency response (on and off-axis) as well as THD and a few other things along with analysis for various speaker drive units. I took the last couple years off due to personal reasons. But I'm gearing back up to do something big, at least for me. I’ve been itching to change things up and move my review format to YouTube and also expand out of raw driver testing and instead provide a wider range of information. So, that's what I'm doing.

The core of my efforts will focus on product reviews and tutorials (i.e., how to use a DSP, how to tune, what to listen for, etc) along with some other miscellaneous things. I will continue to provide objective data when I can/where it makes sense and I plan to do that as a supplement to the YouTube format; providing the data via a new website. I have a long list of ideas that I’ve collected over years. I think I have a few ideas for my reviews you all will really dig.

I have created a Facebook Group page for those who want to follow it. This page will be a way for me to update everyone on progress I make toward completing reviews. If I get a new piece of hardware to test I’ll share it. Links will be posted to reviews. That sort of stuff. It’ll be an extension of my YouTube review page because, frankly, it’s easier to support conversation here than it is on YouTube. Here’s the link: Log into Facebook | Facebook

To be entirely transparent, I hope to be ad-driven at some point and also do some affiliate marketing (i.e., Amazon, Parts-Express, etc) so I can use some of the advertising revenue toward purchasing new test equipment and products to test/review. I don’t see me ever actually making money; breaking even would be nice. I’ve already sunk nearly a grand in to what I need to get going. In order to get to the point where I can monetize videos through YouTube, however, I’ll need to hit 1k subscribers, and some crazy number of hours viewed per month. So, I ask you all, if you are interested in any of the stuff I’ve done and the past or you just want to support what I’m doing, go ahead to my YouTube page and click the subscribe button. I don’t have anything out there at this moment in the way of reviews but I’m already working on some really, really cool stuff. And if you are interested in the items I review in the future, feel free to click any links I provide to my affiliate advertisers so I can get a small percentage of the purchase fee (hey, you were gonna buy it anyway). All that helps me keep this thing rolling and keep me from going in debt in the process.

Here’s a link to my YouTube page:

YouTube

And that’s it… I just ask you to bear with me. I’m not a video editor so I don’t expect to knock this stuff out of the park my first few attempts. But over time, with your feedback, I will hopefully improve the final product and provide an entertaining and educational set of videos. 🙂

Thanks,

Erin

Many of you know that I used to do speaker/driver testing for a number of years for DIYMA before moving on to creating my own site (medleysmusings). If you have no idea what that is, it’s a site I used to post objective data to and share with the community. It was focused on providing Klippel data, frequency response (on and off-axis) as well as THD and a few other things along with analysis for various speaker drive units. I took the last couple years off due to personal reasons. But I'm gearing back up to do something big, at least for me. I’ve been itching to change things up and move my review format to YouTube and also expand out of raw driver testing and instead provide a wider range of information. So, that's what I'm doing.

The core of my efforts will focus on product reviews and tutorials (i.e., how to use a DSP, how to tune, what to listen for, etc) along with some other miscellaneous things. I will continue to provide objective data when I can/where it makes sense and I plan to do that as a supplement to the YouTube format; providing the data via a new website. I have a long list of ideas that I’ve collected over years. I think I have a few ideas for my reviews you all will really dig.

I have created a Facebook Group page for those who want to follow it. This page will be a way for me to update everyone on progress I make toward completing reviews. If I get a new piece of hardware to test I’ll share it. Links will be posted to reviews. That sort of stuff. It’ll be an extension of my YouTube review page because, frankly, it’s easier to support conversation here than it is on YouTube. Here’s the link: Log into Facebook | Facebook

To be entirely transparent, I hope to be ad-driven at some point and also do some affiliate marketing (i.e., Amazon, Parts-Express, etc) so I can use some of the advertising revenue toward purchasing new test equipment and products to test/review. I don’t see me ever actually making money; breaking even would be nice. I’ve already sunk nearly a grand in to what I need to get going. In order to get to the point where I can monetize videos through YouTube, however, I’ll need to hit 1k subscribers, and some crazy number of hours viewed per month. So, I ask you all, if you are interested in any of the stuff I’ve done and the past or you just want to support what I’m doing, go ahead to my YouTube page and click the subscribe button. I don’t have anything out there at this moment in the way of reviews but I’m already working on some really, really cool stuff. And if you are interested in the items I review in the future, feel free to click any links I provide to my affiliate advertisers so I can get a small percentage of the purchase fee (hey, you were gonna buy it anyway). All that helps me keep this thing rolling and keep me from going in debt in the process.

Here’s a link to my YouTube page:

YouTube

And that’s it… I just ask you to bear with me. I’m not a video editor so I don’t expect to knock this stuff out of the park my first few attempts. But over time, with your feedback, I will hopefully improve the final product and provide an entertaining and educational set of videos. 🙂

Thanks,

Erin

I finally got started on the site. Have only had time to get one of my old reviews brought over to the new site so far. It’s gonna take a while to get all the others moved but it’s a start. ��

Erin's Audio Corner

Erin's Audio Corner

After wavering a bit on what to use for measurement hardware/software, I have decided to go back to using Klippel products. I plan to do what I did before which was provide standard data such as impedance, FR, Distortion, Compression, linear xmax, etc. The sweet thing is... this time I'll be using a laser to more accurately measure T/S parameters and notably linear excursion; something too many manufacturers spec incorrectly. I am currently awaiting the final quote from Klippel, though I fear seeing the bill. LOL. I have toiled over creating a gofundme and as much as I hate to appear needy, in order to do what I want to do I may need to do so. But we shall see what the final bill is.

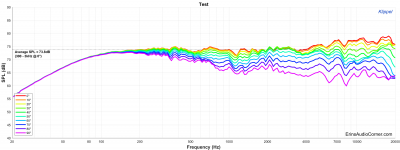

I have also started writing up scripts in Matlab using some of the data available here that I will use to create graphs in the way that I deem most useful (some of the Klippel default outputs in the past were not up to my standard). You can see a couple examples of what I'll be providing below (I used some loudspeaker data posted on another forum).

I have also started writing up scripts in Matlab using some of the data available here that I will use to create graphs in the way that I deem most useful (some of the Klippel default outputs in the past were not up to my standard). You can see a couple examples of what I'll be providing below (I used some loudspeaker data posted on another forum).

Attachments

I just ported over 3 reviews from the old site:

Scanspeak 12m Midrange

HAT L1-Pro R2 Ring Radiator Tweeter

Tectonics 2" BMR Speaker

Links below. Enjoy!

ScanSpeak Revelator 12M/4631-G00 4.5″ Midrange Driver Review

Hyrbrid Audio Technologies L1-Pro-R2 Ring Radiator Driver Review

Tectonic Elements TEBM35C10-4 Miniature BMR(R) Driver Review

Scanspeak 12m Midrange

HAT L1-Pro R2 Ring Radiator Tweeter

Tectonics 2" BMR Speaker

Links below. Enjoy!

ScanSpeak Revelator 12M/4631-G00 4.5″ Midrange Driver Review

Hyrbrid Audio Technologies L1-Pro-R2 Ring Radiator Driver Review

Tectonic Elements TEBM35C10-4 Miniature BMR(R) Driver Review

Well, I got a quote from them this morning. As expected, however, it’s not cheap. Regardless, I’m moving forward and will be sending payment shortly. But I would really appreciate any donations from the community that I can get to help me offset those costs and, namely, to help fund some of the other things I would like to purchase to help me make my testing more efficient and accurate.

If you don’t mind helping out, you can use the link below to contribute to via PayPal (they take 3%, I’m OK with that):

https://www.erinsaudiocorner.com/contribute/

Some of the things I'll be able to provide are:

Frequency Response on/off-axis (and from that I can calculate power response, early reflection windows, etc)

Harmonic Distortion

IMD

Max SPL (using the Tone-Burst Module)

Thiele-Small Parameters

Large signal parameters

Linear Xmax using a laser for maximum accuracy

Various other items

If you don’t care about the rest of the details then there’s no need to read any further. However, if you’re interested in what your donations would be going toward, keep on reading…

I want to provide as much accurate information as I can about drive units, speakers and whatever miscellaneous ‘tasks’ I take on. IMHO, Klippel products will provide far more depth of knowledge than anything else and that’s why I’ve chosen their product(s). But I also want to keep my hobby/family balance. Testing takes up a good deal of time; but it's not so much the "test" as it is the setup/takedown time: cutting baffles, setting up the measurement rigs, getting the cabling out and running all the wires, fixing the driver/speaker to the test stand, and then writing up the report. In the time it takes to get prepped for a test I can complete another test cycle.

To help with accuracy and efficiency, I also hope to build a dedicated "test" space in my attic. I have about 11x17 feet that I'll need to floor, wall, and insulate to make it a test room. The reasons this is important to me are:

1) Scientifically speaking, the space would be large enough to push the first reflection out another 1 or 2 milliseconds which may not sound like much but is another 200hz or so of accuracy in my measurements. 200hz is a lot when you're expanding that over multiple octaves.

2) It gives me a fully repeatable environment to work within whereas my garage is a state of constant flux with temperature, humidity and ... stuff. Having a dedicated area means that the ambient conditions are within reason throughout the year but also it means that I won't have to spend hours setting up gear and taking it down to complete a couple tests which would help me complete more tests over time.

3) If I were to go this route I could also build an ‘infinite’ baffle to help with drive-unit testing.

Another thing that would help immensely is a small, tabletop, CNC. For raw driver testing I use a large baffle which has a cut-out for inserting smaller baffles. These smaller baffles are the pieces that the raw drivers are attached to. In my previous years of testing I didn't have the ability to surface mount complex drivers or oversized flange drivers. This was a detriment to my results (I always noted when that was the case). Surface mounting is the proper way to test drivers. I do own a router but the time it takes to cut flush-mount surfaces for some drivers … well, it adds up over time. Therefore, I would also like to purchase a small, table-top CNC router so I can cut my baffles to the exact dimensions needed for a driver cut-out. I've got my eye on an item that is just large enough to cut the baffle templates I need.

The third thing is having an automated turntable for polar measurements (on/off-axis frequency response). Now, I can build one from wood … I’ve done it before. But it’s a manual turning system which consists of: measure speaker, go turn speaker, measure speaker, go turn speaker… doing that in 5 to 10 degree increments over 90 to 180 degrees takes time. So, it would be really nice to use one that’s automated and works with the Klippel where I could click the run button and let it measure and rotate automatically. Again, this helps with repeatability and accuracy. But these are not cheap, either. I’ve gotten a couple quotes back > $3k. So, this is probably more of a pipedream at this point.

Obviously I wouldn’t be doing this if I didn’t enjoy it and feel like I’m learning from it as well so I’m not about to cry “woe, is me” here. But presenting data to the masses requires an extra level of accuracy and robustness that throwing together a simple test setup in my spare bedroom and caveating to the nth degree cannot provide; I know this from experience. So anything you can donate to help me with that would really and truly be appreciated.

Thanks again,

- Erin

If you don’t mind helping out, you can use the link below to contribute to via PayPal (they take 3%, I’m OK with that):

https://www.erinsaudiocorner.com/contribute/

Some of the things I'll be able to provide are:

Frequency Response on/off-axis (and from that I can calculate power response, early reflection windows, etc)

Harmonic Distortion

IMD

Max SPL (using the Tone-Burst Module)

Thiele-Small Parameters

Large signal parameters

Linear Xmax using a laser for maximum accuracy

Various other items

If you don’t care about the rest of the details then there’s no need to read any further. However, if you’re interested in what your donations would be going toward, keep on reading…

I want to provide as much accurate information as I can about drive units, speakers and whatever miscellaneous ‘tasks’ I take on. IMHO, Klippel products will provide far more depth of knowledge than anything else and that’s why I’ve chosen their product(s). But I also want to keep my hobby/family balance. Testing takes up a good deal of time; but it's not so much the "test" as it is the setup/takedown time: cutting baffles, setting up the measurement rigs, getting the cabling out and running all the wires, fixing the driver/speaker to the test stand, and then writing up the report. In the time it takes to get prepped for a test I can complete another test cycle.

To help with accuracy and efficiency, I also hope to build a dedicated "test" space in my attic. I have about 11x17 feet that I'll need to floor, wall, and insulate to make it a test room. The reasons this is important to me are:

1) Scientifically speaking, the space would be large enough to push the first reflection out another 1 or 2 milliseconds which may not sound like much but is another 200hz or so of accuracy in my measurements. 200hz is a lot when you're expanding that over multiple octaves.

2) It gives me a fully repeatable environment to work within whereas my garage is a state of constant flux with temperature, humidity and ... stuff. Having a dedicated area means that the ambient conditions are within reason throughout the year but also it means that I won't have to spend hours setting up gear and taking it down to complete a couple tests which would help me complete more tests over time.

3) If I were to go this route I could also build an ‘infinite’ baffle to help with drive-unit testing.

Another thing that would help immensely is a small, tabletop, CNC. For raw driver testing I use a large baffle which has a cut-out for inserting smaller baffles. These smaller baffles are the pieces that the raw drivers are attached to. In my previous years of testing I didn't have the ability to surface mount complex drivers or oversized flange drivers. This was a detriment to my results (I always noted when that was the case). Surface mounting is the proper way to test drivers. I do own a router but the time it takes to cut flush-mount surfaces for some drivers … well, it adds up over time. Therefore, I would also like to purchase a small, table-top CNC router so I can cut my baffles to the exact dimensions needed for a driver cut-out. I've got my eye on an item that is just large enough to cut the baffle templates I need.

The third thing is having an automated turntable for polar measurements (on/off-axis frequency response). Now, I can build one from wood … I’ve done it before. But it’s a manual turning system which consists of: measure speaker, go turn speaker, measure speaker, go turn speaker… doing that in 5 to 10 degree increments over 90 to 180 degrees takes time. So, it would be really nice to use one that’s automated and works with the Klippel where I could click the run button and let it measure and rotate automatically. Again, this helps with repeatability and accuracy. But these are not cheap, either. I’ve gotten a couple quotes back > $3k. So, this is probably more of a pipedream at this point.

Obviously I wouldn’t be doing this if I didn’t enjoy it and feel like I’m learning from it as well so I’m not about to cry “woe, is me” here. But presenting data to the masses requires an extra level of accuracy and robustness that throwing together a simple test setup in my spare bedroom and caveating to the nth degree cannot provide; I know this from experience. So anything you can donate to help me with that would really and truly be appreciated.

Thanks again,

- Erin

Hello, do you happen to have the FRD and ZMA files for the Aura NS3 that you tested here?

https://www.erinsaudiocorner.com/driveunits/aurasound-ns3-193-8a1/

https://www.erinsaudiocorner.com/driveunits/aurasound-ns3-193-8a1/

- Home

- Member Areas

- The Lounge

- Erin's Audio Corner (my new site/YouTube page)