Hello everyone,

I am planning to rehouse a Philips AD9032 EI output transformer. This transformer did not have any end bells, just some brackets, and a bakelite board with solder lugs for the windings.

Since the core is standard EI-75 type, I want to attach end bells to it to make it safer and prettier.

I am aware of the need to ensure that metallic screws that go through the laminations holes cannot touch the laminations, thus shorting them and defeating their purpose. But I have the following additional questions:

(1) Do they need to be electrically isolated from both end bells? Or could they make contact with one of them?

(2) Do the bells need to be isolated from the core laminations? For example, do I have to insert paper tape where they touch? Or, same question as in (1), can I isolate one of them from the core and leave the other one without isolation?

My bells attract a fridge magnet, so I would assume they are made of galvanized steel.

I am planning to rehouse a Philips AD9032 EI output transformer. This transformer did not have any end bells, just some brackets, and a bakelite board with solder lugs for the windings.

Since the core is standard EI-75 type, I want to attach end bells to it to make it safer and prettier.

I am aware of the need to ensure that metallic screws that go through the laminations holes cannot touch the laminations, thus shorting them and defeating their purpose. But I have the following additional questions:

(1) Do they need to be electrically isolated from both end bells? Or could they make contact with one of them?

(2) Do the bells need to be isolated from the core laminations? For example, do I have to insert paper tape where they touch? Or, same question as in (1), can I isolate one of them from the core and leave the other one without isolation?

My bells attract a fridge magnet, so I would assume they are made of galvanized steel.

From the very many OPTs I've seen and worked with, mostly PP types, I have never seen any extra insulation material between the end bell and the end laminations of the core. Apparently the protective coating each lamination has is sufficient. I assume this would apply to SE types as well. As far as the bolts go, at least one end always has a fiber washer. Usually on the bolt's head end. One on each end wouldn't hurt but probably isn't used for cost saving reasons. Sometimes the length of the bolt has a covering like heat shrink tubing, but not always depending on the manufacture. Usually the holes they pass through in the lams are sufficiently larger then the bolt itself.

You haven't shown a picture of your tranny, but I would be more concerned with keeping the wiring insulated that's comming out of the coil when a metal cover is put over it.

You haven't shown a picture of your tranny, but I would be more concerned with keeping the wiring insulated that's comming out of the coil when a metal cover is put over it.

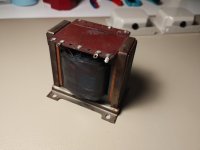

Here are some photos of the restoration - I removed the original brackets, soldered wires, used heatshrink tube and insulating tape, used paper and tape to provide a firm wrap around everything to hold them in place.

It is going well so far, and from your response I deduce that I was in the right, thinking about insulating only one bell from the screws.

Apart from that, I suppose that the screws for attaching the bells to the laminations should not be magnetic (for example galvanized steel), but instead non-magnetic (stainless steel), to follow the "unaltered core permeability" strategy. Is this correct or overkill?

It is going well so far, and from your response I deduce that I was in the right, thinking about insulating only one bell from the screws.

Apart from that, I suppose that the screws for attaching the bells to the laminations should not be magnetic (for example galvanized steel), but instead non-magnetic (stainless steel), to follow the "unaltered core permeability" strategy. Is this correct or overkill?

Attachments

Today I went and checked, with a small magnet, several of my OPTs on the shelf. All seemed to have magnetic bolts. And these are good American made trannies, Stancor & Thordarson, not some ersatz Chicom units. Although non-magnetic SS wouldn't hurt. But remember that all SS is not non-magnetic. Only the austenitic 300 series is.