Hi,

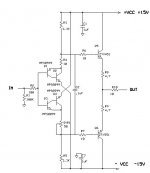

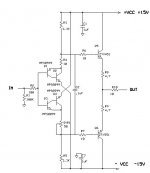

Some years ago I bought from eBay these two diamond buffer kits and now I was thinking in using one of them as a unity gain preamplifier. What I'd like to know is if any of them would suit as a high-quality unity gain preamp and if so, wich one is the best. I see one has a DC servo and the other is simpler. The one with the servo has polyester caps wich perhaps is not good. Maybe put some polypropylen? The one without the servo - is it dangerous to use it dc coupled with the amp?

Would a 100k pot fit any of them as volume control?

Many thanks for your answers!

View attachment HDAM Buffer DIY Zone.pdf

Some years ago I bought from eBay these two diamond buffer kits and now I was thinking in using one of them as a unity gain preamplifier. What I'd like to know is if any of them would suit as a high-quality unity gain preamp and if so, wich one is the best. I see one has a DC servo and the other is simpler. The one with the servo has polyester caps wich perhaps is not good. Maybe put some polypropylen? The one without the servo - is it dangerous to use it dc coupled with the amp?

Would a 100k pot fit any of them as volume control?

Many thanks for your answers!

View attachment HDAM Buffer DIY Zone.pdf

I've been experimenting with the DC servo one and seems to blur a little the music. Also, removing the OPA2132 (the servo) the sound seems more detailed and higher in volume. Is this normal?

Thanks.

Thanks.

No.

The servo is maybe not designed properly.

There is an excellent thread on servos from a couple of years ago. Gootee was deeply involved and developed a simulator model.

The servo is maybe not designed properly.

There is an excellent thread on servos from a couple of years ago. Gootee was deeply involved and developed a simulator model.

Thanks, I was suspecting the same thing. I'll google it. Anyway, is the servo mandatory for this kind of circuit?No.

The servo is maybe not designed properly.

There is an excellent thread on servos from a couple of years ago. Gootee was deeply involved and developed a simulator model.

Thanks.

Servo or coupling caps are needed for almost any circuit. One puts caps directly in the signal path. The other puts caps indirectly in the signal path, by putting them in the feedback path. You choose.

Can't I avoid both with carefully matched transistors? I was hoping to go capless and servoless but I can't, right?

I can thermal couple the transistors with some thermal glue but I don't know if this is good enough. I think this is what is been done with the Mezmerize buffer, at least I think they don't use a servo.Can you ensure no thermal gradients too?

I just changed the 0.2uF polyester caps of the servo with one 0.1uF MKP1837. The RC constant was about 0.03 and now is 0.016 Hz. I don't know if is the polypropylen or the RC constant, but the sound improved. It's not as transparent as I hopped for but it's some improvement. Anyway, the volume goes down with the OPA in place. No servo, the volume is a lot higher. Could this be an opamp issue? - I'm using OPA2132 not the OPA2134 from the BOM I have. Could I ask someone with more knowledge than I to check the servo design for me, please?

Thanks.

Thanks.

The Servo and the Servo's Time Constant should not change the volume (output signal level).

If 0.2uF is 0.03Hz then 0.1uF is 0.06Hz, not 0.016Hz

Do you measure 0.2uF or is it marked 0.2uF? The usual E6 value is 0.22uF or 220nF or 224 (for 220000pF).

If you do opt for DC coupled through the Power Amp then you must accept the risk of damage at some time.

If you can't accept that risk then you must fit detection and protection as the least option.

Go to the servo thread. All the design and comment and simulation is in there.

If 0.2uF is 0.03Hz then 0.1uF is 0.06Hz, not 0.016Hz

Do you measure 0.2uF or is it marked 0.2uF? The usual E6 value is 0.22uF or 220nF or 224 (for 220000pF).

If you do opt for DC coupled through the Power Amp then you must accept the risk of damage at some time.

If you can't accept that risk then you must fit detection and protection as the least option.

Go to the servo thread. All the design and comment and simulation is in there.

Last edited:

I think 0.03 and 0.016 are time constants in seconds, not frequencies in Hz. If this is the dominant pole in the servo, then it is a bit close to the LF end of the audio band so you are likely to get a lumpy bass response. You might interpret this as an improvement, especially if you like reggae or organ pedal music.

I am always baffled why some people seem to prefer a complicated servo to a simple coupling capacitor. Maybe they have heard too many old wive's tales?

I am always baffled why some people seem to prefer a complicated servo to a simple coupling capacitor. Maybe they have heard too many old wive's tales?

It's two 100nF caps in parallel thus giving 200nF total.Do you measure 0.2uF or is it marked 0.2uF?

That's what's bothering me. Somehow the servo is loading the buffer and lowering the output signal. I read the OPA2132 and 2134 datasheets to see if I'd spot some significant difference that justified the loading but they seem almost identical.The Servo and the Servo's Time Constant should not change the volume (output signal level).

I have the power amp dc protected but i'll use the servo or the cap just in case something goes wrong. I'm leaning towards the servo because a large output cap would have to be an electrolytic and these colour the sound to much for my liking.If you can't accept that risk then you must fit detection and protection as the least option.

I believe the time constant is R*C, that is 0.2 for 200nF and 0.1 for 100nF (C is in microfarad and R is 1 Mohm). I did R*C/2*PI and I got 0.0318 and 0.0159 Hz respectively. This was the way I calculated.I think 0.03 and 0.016 are time constants in seconds, not frequencies in Hz.

I would split R13 in two and put a servo there in the midle. I call that a bias servo. That is even more "indirect" in the signal path. It also avoids a cap at the input.

If you have two channels of power amp and they are fed by two channels of pre-amp then all you need is a pair of <=10uF polypropylene metalised film capacitors to ensure AC coupling.

You can choose to put them in the pre-amp or in the power amp.

You do not need both locations. You certainly don't need electrolytic caps for coupling/DC blocking.

You can choose to put them in the pre-amp or in the power amp.

You do not need both locations. You certainly don't need electrolytic caps for coupling/DC blocking.

Some points for your understanding

- The buffer circuit with the servo will have low offset in the

millivolt range or less even with the IC disengaged. There

is no need for a servo here.

- It will have no DC gain because of the input coupling cap.

This cap can be taken away if the source is free of DC.

Most sources will have an output cap anyway.

- The servo does not load the buffer circuit. It loads the input

source with 4k7 ohms via R9. With the servo disconnected

you have over 100 kohms at the input. This is the reason for

the noticed volume difference and may be the reason for a

sound difference. The input source apparently has high

internal impedance.

- The volume difference you noticed is not an issue of the

type of opamp for the reason above. R9 may be increased

for a reduction of this effect.

- The buffer circuit with the servo will have low offset in the

millivolt range or less even with the IC disengaged. There

is no need for a servo here.

- It will have no DC gain because of the input coupling cap.

This cap can be taken away if the source is free of DC.

Most sources will have an output cap anyway.

- The servo does not load the buffer circuit. It loads the input

source with 4k7 ohms via R9. With the servo disconnected

you have over 100 kohms at the input. This is the reason for

the noticed volume difference and may be the reason for a

sound difference. The input source apparently has high

internal impedance.

- The volume difference you noticed is not an issue of the

type of opamp for the reason above. R9 may be increased

for a reduction of this effect.

Last edited:

Thank you as-audio!

Let me see if I fully understand: With the servo connected because the output of the opamp has very low resistance (idealy zero) the input sees only 4.7K (4.7k // 100k) to ground of input impedance. Without the servo, R7 defines the input impedance. Because I'm using a 100k input potenciometer, impedance is matched better by R7 alone. Is my reasoning good?

If I want to use the 100k pot at the input (for volume control) can I increase R9 to 200K so paralleled with R7 I get 100k matching the pot? What about the servo, it's functioning wouldn't be afected by doing this?

Another question: What's the purpose of R11 and C26? Is it a low pass filter for the opamp?

Thank you! 🙂

Mistery solved! Thanks, as-audio!🙂t. It loads the input

source with 4k7 ohms via R9. With the servo disconnected

you have over 100 kohms at the input.

Let me see if I fully understand: With the servo connected because the output of the opamp has very low resistance (idealy zero) the input sees only 4.7K (4.7k // 100k) to ground of input impedance. Without the servo, R7 defines the input impedance. Because I'm using a 100k input potenciometer, impedance is matched better by R7 alone. Is my reasoning good?

If I want to use the 100k pot at the input (for volume control) can I increase R9 to 200K so paralleled with R7 I get 100k matching the pot? What about the servo, it's functioning wouldn't be afected by doing this?

I have got conflicting answers about this... 😕 Would thermal drift be an issue?The buffer circuit with the servo will have low offset in the

millivolt range or less even with the IC disengaged. There

is no need for a servo here.

Another question: What's the purpose of R11 and C26? Is it a low pass filter for the opamp?

Thank you! 🙂

With the servo connected because the output of the opamp has very low resistance (idealy zero) the input sees only 4.7K (4.7k // 100k) to ground of input impedance. Without the servo, R7 defines the input impedance. Because I'm using a 100k input potenciometer, impedance is matched better by R7 alone.

Yes.

The buffer circuit with the servo will have low offset in the

millivolt range or less even with the IC disengaged. There

is no need for a servo here.

I have got conflicting answers about this... Would thermal drift be an issue?

No.

R11, C26 is a low pass before the buffer.

This combination works only if the servo is engaged. C26 should be connected to ground as ususal.

If I want to use the 100k pot at the input (for volume control) can I increase R9 to 200K so paralleled with R7 I get 100k matching the pot? What about the servo, it's functioning wouldn't be afected by doing this?

Try to exchange R9 and R7 if you insist on a servo.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analog Line Level

- Diamond buffer kits any good for preamp?