I shall soon be the owner of an immaculate DP-57M for a song.

Downside is that the platter spins very, very fast and doesn’t respond to the controls. I’ve done a bit of googling and one of the reasons could be 1) the pickup head being too far from the platter.

2) the platter has lost its magnetic markings. Is this one mark or multiple marks?

3) The main microprocessor is toast.

2 and 3 means I have an very pretty paperweight.

Since it is a 2 phase AC motor can it be powered by Bills multi phase PS?

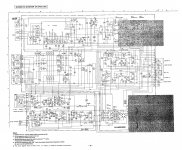

There are 3 wires going to the motor showing 2 coils. I will try and post a snippet from the circuit diagram.

Thanks,

kffern

Downside is that the platter spins very, very fast and doesn’t respond to the controls. I’ve done a bit of googling and one of the reasons could be 1) the pickup head being too far from the platter.

2) the platter has lost its magnetic markings. Is this one mark or multiple marks?

3) The main microprocessor is toast.

2 and 3 means I have an very pretty paperweight.

Since it is a 2 phase AC motor can it be powered by Bills multi phase PS?

There are 3 wires going to the motor showing 2 coils. I will try and post a snippet from the circuit diagram.

Thanks,

kffern

Last edited:

I did try to upload the service manual but it is too large and I couldn't extract pages as it is locked. It is on vinylengine.

The section around the motor of the circuit diagram is dark. the rest is OK.

kffern

The section around the motor of the circuit diagram is dark. the rest is OK.

kffern

I was able to clone the schematic page. Still working through the design, but it looks to be a farily standard PLL control. If the speed is too fast, that would indicate there is a reference signal (crystal) but no feed back signal. There are alignment diagrams as well as sample waveform graphics in the manual. Have you tested any of those points?

Attachments

Thanks Pyramid.

I hadn't picked it up when I posted. I had a brief look at it. Collected it after work yesterday and managed to get it working at the correct speed. It was the pickup head that needed aligning. It has to be very close to the platter and just off from perpedicular. I might put a drop of glue on the plate holding the head so it doesnt move.

I don't have the tonearm counterweights so havent played a record. Hopefully he still has them.

Tested with handheld rpm sensor and it is dead on 33.3 and 45.

I plan to open it up and check if the caps have been changed.

I'm sure there are a few non working units that can do with a new power supply.

Kffern

I hadn't picked it up when I posted. I had a brief look at it. Collected it after work yesterday and managed to get it working at the correct speed. It was the pickup head that needed aligning. It has to be very close to the platter and just off from perpedicular. I might put a drop of glue on the plate holding the head so it doesnt move.

I don't have the tonearm counterweights so havent played a record. Hopefully he still has them.

Tested with handheld rpm sensor and it is dead on 33.3 and 45.

I plan to open it up and check if the caps have been changed.

I'm sure there are a few non working units that can do with a new power supply.

Kffern

The inner rim (directly under the outer rim visible from the top of the turntable motor) contains a PWM encoded control signal. This is created in exactly the same way magnetic tape is created, only in this case instead of being deposited on 1.0 micron mylar, it's on aluminum.

Naive people, in particular eBay sellers, will often "clean up" DENON turntables. Touching the mag strip will almost certainly damage it; any chemical, even water, and the application of the slightest amount of elbow grease will destroy it.

When that happens, the platter spins at a high rate of speed and cannot be controlled. There is no cure ... you need to find a replacement platter, which is akin to finding an entire motor.

Mercifully that wasn't the case with your table. But going forward ... don't touch that part of the underside of the platter. Ever.

You have an awesome machine there. The DENON AC Direct Drive motor system is far superior to the more common Matsushita DC Direct Drive system. Even better, you have one of the premium motor models.

Unlike Matsushita (Technics, Panasonic), DENON did not license their motor technology, so there is only one way to enjoy the system. Unlike the DC system, where the platter speed is indirectly determined by a feedback system, the AC DD motor reads the platter speed directly.

It is a very smooth, very high torque motor; in many respects it offers the advantages of belt drive and direct drive combined. It is sad that the DENON of today only use the DC type of DD motor in their 'tables.

The motor is very easy to remove and place into a different plinth. Obviously that also means you could install the tonearm of your choice if you like.

Naive people, in particular eBay sellers, will often "clean up" DENON turntables. Touching the mag strip will almost certainly damage it; any chemical, even water, and the application of the slightest amount of elbow grease will destroy it.

When that happens, the platter spins at a high rate of speed and cannot be controlled. There is no cure ... you need to find a replacement platter, which is akin to finding an entire motor.

Mercifully that wasn't the case with your table. But going forward ... don't touch that part of the underside of the platter. Ever.

You have an awesome machine there. The DENON AC Direct Drive motor system is far superior to the more common Matsushita DC Direct Drive system. Even better, you have one of the premium motor models.

Unlike Matsushita (Technics, Panasonic), DENON did not license their motor technology, so there is only one way to enjoy the system. Unlike the DC system, where the platter speed is indirectly determined by a feedback system, the AC DD motor reads the platter speed directly.

It is a very smooth, very high torque motor; in many respects it offers the advantages of belt drive and direct drive combined. It is sad that the DENON of today only use the DC type of DD motor in their 'tables.

The motor is very easy to remove and place into a different plinth. Obviously that also means you could install the tonearm of your choice if you like.

Last edited:

The inner rim (directly under the outer rim visible from the top of the turntable motor) contains a PWM encoded control signal. This is created in exactly the same way magnetic tape is created, only in this case instead of being deposited on 1.0 micron mylar, it's on aluminum.

Naive people, in particular eBay sellers, will often "clean up" DENON turntables. Touching the mag strip will almost certainly damage it; any chemical, even water, and the application of the slightest amount of elbow grease will destroy it.

When that happens, the platter spins at a high rate of speed and cannot be controlled. There is no cure ... you need to find a replacement platter, which is akin to finding an entire motor.

Mercifully that wasn't the case with your table. But going forward ... don't touch that part of the underside of the platter. Ever.

You have an awesome machine there. The DENON AC Direct Drive motor system is far superior to the more common Matsushita DC Direct Drive system. Even better, you have one of the premium motor models.

Unlike Matsushita (Technics, Panasonic), DENON did not license their motor technology, so there is only one way to enjoy the system. Unlike the DC system, where the platter speed is indirectly determined by a feedback system, the AC DD motor reads the platter speed directly.

It is a very smooth, very high torque motor; in many respects it offers the advantages of belt drive and direct drive combined. It is sad that the DENON of today only use the DC type of DD motor in their 'tables.

The motor is very easy to remove and place into a different plinth. Obviously that also means you could install the tonearm of your choice if you like.

Thanks for the advice. I did clean the head lightly but luckily not the platter apart from blowing off some dust. I'm still waiting for the tonearm counterweights and not sure if I will ever get them. There is one set on ebay I may have to buy. I have a Micro 505 II on my Lenco but the mounting distance is a bit smaller.

If anyone has counterweights or any other good spares (platter etc) I might be interested.

Regards,

kffern

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Denon DP-57M speed problem