Hi,

Please could I have a sense check and some advice... I'm planning on building Troels Gravesen TL3 speaker...I've already bought the drivers, crossover components etc....

I've purchased 4mm mass vinyl sheet to line the cabinet walls with, as I've used it before and found it to be benefical. This product...

I had planned on lining the internal walls of the midrange and main cabinet with Rockwool RW5 - 100kg density. See attached sheet that shows the sound absorption coefficient.

I'm having trouble sourcing this material, so was going to purchase a 25mm thick Rockwool acoustic slab product at 200kg/m3 density....

I'm not sure the exact crossover frequency of the bass unit, but I'm guessing it's 1k mark...

My question is, looking at the chart I believe the rockwool would be quite efficient at absorbing a lot of the frequencies below the 1k mark... Would this have the effect of sucking out all of the bass?

If so, I was thinking of maybe boxing in the rear of the horn with the slab product... And just over laying the acousilux product over the sheet vinyl. I omitted the felt from the kit... But could always buy some locally if needed.

Please could I have a sense check and some advice... I'm planning on building Troels Gravesen TL3 speaker...I've already bought the drivers, crossover components etc....

I've purchased 4mm mass vinyl sheet to line the cabinet walls with, as I've used it before and found it to be benefical. This product...

I had planned on lining the internal walls of the midrange and main cabinet with Rockwool RW5 - 100kg density. See attached sheet that shows the sound absorption coefficient.

I'm having trouble sourcing this material, so was going to purchase a 25mm thick Rockwool acoustic slab product at 200kg/m3 density....

I'm not sure the exact crossover frequency of the bass unit, but I'm guessing it's 1k mark...

My question is, looking at the chart I believe the rockwool would be quite efficient at absorbing a lot of the frequencies below the 1k mark... Would this have the effect of sucking out all of the bass?

If so, I was thinking of maybe boxing in the rear of the horn with the slab product... And just over laying the acousilux product over the sheet vinyl. I omitted the felt from the kit... But could always buy some locally if needed.

Attachments

TL3? That's 'The Loudspeaker 3'? That should kick ***! Why not just use thick felt (carpet underlay?) over your mass vinyl? I mean, if it was good enough for Troel's ...

I'm only considering other materials as I followed Troels instructions for his Audio Technology Classic 3 way design and always found it a bit bright, until I filled the tweeter and midrange areas with dense rockwool batt material. It really helped to tone down the speaker, helping it sound more detailed and relaxing to listen to.

I've been thinking about it, and I think I'll do the same and experiment with rockwool batt in the midrange compartment instead of the sheep's wool and I'll locally surround the horn internally with rockwool material. If I don't like it, could always take it out.

I've been thinking about it, and I think I'll do the same and experiment with rockwool batt in the midrange compartment instead of the sheep's wool and I'll locally surround the horn internally with rockwool material. If I don't like it, could always take it out.

Hi,

Please could I have a sense check and some advice... I'm planning on building Troels Gravesen TL3 speaker...I've already bought the drivers, crossover components etc....

I've purchased 4mm mass vinyl sheet to line the cabinet walls with, as I've used it before and found it to be benefical. This product...

I had planned on lining the internal walls of the midrange and main cabinet with Rockwool RW5 - 100kg density. See attached sheet that shows the sound absorption coefficient.

I'm having trouble sourcing this material, so was going to purchase a 25mm thick Rockwool acoustic slab product at 200kg/m3 density....

I'm not sure the exact crossover frequency of the bass unit, but I'm guessing it's 1k mark...

My question is, looking at the chart I believe the rockwool would be quite efficient at absorbing a lot of the frequencies below the 1k mark... Would this have the effect of sucking out all of the bass?

If so, I was thinking of maybe boxing in the rear of the horn with the slab product... And just over laying the acousilux product over the sheet vinyl. I omitted the felt from the kit... But could always buy some locally if needed.

Hello,

I will save the full anti-rockwool rant.

Rockwool is manmade asbestos. It may take 20 years to kill you but is a rotten way to go.

Avoid it.

Thanks DT

It's not lethal like asbestos as the fibres are too large to centre your lungs.

Also, I'm only considering dense slabs that don't really have any loose fibres like the typical loose roll product which typically has a density of 22kg/m3 vs the slab product at 100kg or 200kg/m3 for the product being considered.

Also, I'm only considering dense slabs that don't really have any loose fibres like the typical loose roll product which typically has a density of 22kg/m3 vs the slab product at 100kg or 200kg/m3 for the product being considered.

It's not lethal like asbestos as the fibres are too large to centre your lungs.

Also, I'm only considering dense slabs that don't really have any loose fibres like the typical loose roll product which typically has a density of 22kg/m3 vs the slab product at 100kg or 200kg/m3 for the product being considered.

If you pack your enclosures with dense slabs of insulation you will find that you effectively are reducing the volume of your enclosures. The denser the dense slabs are the more like slabs of plywood they become.

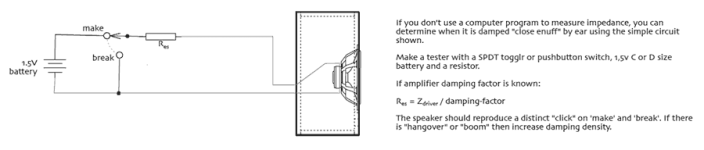

I suggest that you make some measurements.

With your sealed mid enclosure do an series of impedance sweeps first with little or no stuffing, use a light loose and fluffy amount at first. Gradually increase the amount and density of the insulation. At first you see and apparent increase in enclosure volume and a decrease in resonance frequency. Continue increasing the quantity and density of the insulation, the resonant frequency will increase.

If you have the tools handy also place a microphone in the sealed enclosure and record the step response. It is interesting to watch sound pressures reflect around inside the enclosure as the amount and density of stuffing is adjusted. You know, MIB Microphone in the Box kind of stuff.

High density insulation batts are not your friend.

Thanks DT

Hi, on previous boxes I used https://huntonfiber.co.uk/ wood fiber insulation, which is quite dense. I lined all the walls with 5cm thick slabs and impedance plot shows reduced resonant frequency so it worked just fine. Perhaps not the best, but better than nothing as all the midrange wiggle got smoothed, which is the main purpose I think.

Hi, on previous boxes I used https://huntonfiber.co.uk/ wood fiber insulation, which is quite dense. I lined all the walls with 5cm thick slabs and impedance plot shows reduced resonant frequency so it worked just fine. Perhaps not the best, but better than nothing as all the midrange wiggle got smoothed, which is the main purpose I think.

Hello,

Wiggle?

Is that wiggle in the impedance plot, frequency response or the step response?

My preference for insulation board is 1in or 2.5cm spaced away from the inside surface of the enclosure. Some sound amplitude will reflect back from the surface of the insulation board. Some sound will attenuate passing through the insulation board then reflect back from the back side of the insulation board with more attenuation on the return trip. Of the sound that passes through the insulation board it will reflect back from the the enclosure wall and be attenuated again as it was heading the other direction. All this happens over time and distance, there will be summing of +pressure with out of phase -pressure resulting in lower inside enclosure SPL. Low frequencies do not attenuate as much as higher frequencies.

Short version: add a air space between the insulation board and the enclosure wall for much improved in enclosure sound attenuation.

Thanks DT

Hi,

wiggle in the impedance plot.

Yeah it could work even better that way, get the material more into mode velocity node, it's all pressure near the walls. I had the stuff in my warehouse so used it. Put it tight between braces so it stays nicely against the box wall, put some fabrik over to contain dust and fibers and make sure it stays in place. Simple knock test gives feeling wall resonances are also damped some, which might happen with small air space as well. Walls need more work, I thin kthisnis fine for the airspace though. Anyway, very practical to do it this way.

wiggle in the impedance plot.

Yeah it could work even better that way, get the material more into mode velocity node, it's all pressure near the walls. I had the stuff in my warehouse so used it. Put it tight between braces so it stays nicely against the box wall, put some fabrik over to contain dust and fibers and make sure it stays in place. Simple knock test gives feeling wall resonances are also damped some, which might happen with small air space as well. Walls need more work, I thin kthisnis fine for the airspace though. Anyway, very practical to do it this way.

- Home

- Loudspeakers

- Multi-Way

- Cabinet lining and rockwool slabs