If I laminate soft pine with rock maple along the grain will I have any separation or cracking issues due to differing rates of expansion and contraction?

Both are relatively dry but Ive never tried this before. Im trimming out the edges of a pine surface with the maple to make it look more substantial. I might iron some maple veneer over the pine first. Other than that it wont have any stresses on it. Thanks in advance.

Both are relatively dry but Ive never tried this before. Im trimming out the edges of a pine surface with the maple to make it look more substantial. I might iron some maple veneer over the pine first. Other than that it wont have any stresses on it. Thanks in advance.

I guess that was kind of a dumb question. I went and glued it up so I guess Ill find out in the long run 😛

Ironing veneer over a large section of solid wood is another story

I use acclimated glued up strips quarter sawen white pine as a sub-strait in some veneer projects, the key word being quarter sawen

I use acclimated glued up strips quarter sawen white pine as a sub-strait in some veneer projects, the key word being quarter sawen

Last edited:

I agree, it was a dumb question. 😀

Hey wait I thought no question was too dumb if the answer teaches you something 😀

I got 6 sheets off pine laminate, cleaning out a garage space for someone and I was told I can have it. The kind of stuff you see in home depo or rona thats usually shrink wrapped. Since taking it inside its warping.

I have another question, it may be dumb it may not be 😛 How does one straighten it out? It would look nice as column speakers, perhaps. What to do...

A magic wan would help.

or you could try laying a wet towel on the concave side, but when it dries it could likely cup again. the culprit is most likely a flat sawen board or two in the same orientation near the center of the glue up and the direction of the cup is the opposite of the direction of the curved growth rings on the end grain of the panel.

Sorry but it sounds like you have some kilm dried firewood unless you have access to a saw to rip them down to 3 or 4 pieces re joint alternate the flat sawen growth rings and glue them back together.

or you could try laying a wet towel on the concave side, but when it dries it could likely cup again. the culprit is most likely a flat sawen board or two in the same orientation near the center of the glue up and the direction of the cup is the opposite of the direction of the curved growth rings on the end grain of the panel.

Sorry but it sounds like you have some kilm dried firewood unless you have access to a saw to rip them down to 3 or 4 pieces re joint alternate the flat sawen growth rings and glue them back together.

staring with plywood is lots simpler - but yes, if you read up on woodworking there are lots of things to learn about dimensional stability, drying, seasonal humidity changes...

You can buy veneered chipboard so I would have thought it would be ok to glue veneer to soft wood.

Chipboard is a stable sub-strait it does not change in dimension with changes in humidity, the laminated panels as SS said where moved from what sounds like a unheated cold space to a heated space, since the humid summer weather is over and the indoor air is dryer moisture content in the wood is dropping, unfortunately flat sawen lumber will shrink more on the outside side of the curved growth rings.

When gluing up flat sawen boards the curved growth rings should be alternated up and down to create a wash board affect across the panel instead of all wanting to cup in one direction.

When selecting these laminated panels, looking at the end grain growth ring orientation is important for stability. Ideally quartered or rift sawen is much stabler.

When selecting these laminated panels, looking at the end grain growth ring orientation is important for stability. Ideally quartered or rift sawen is much stabler.

Yes I believe they poorly arranged the boards before gluing. I weighted it and it did straighten out only to bow again soon after. It will make good fire starter in the new porch stove.

I don,t think any attention is payed to in these mass production shops when they are pumping out thousands of board feet a day its all about quantity not quality

kind of a dumb

I had a bubinga batch sawn to my specifications, intended for a 7 ¼ ' x 3 ¼ ' dining room table.

Edges are 2'' square solid, locking up a sandwich composite of 2-sided bubinga 4'' width shelves with a hdf core, epoxy glued.

The 4''x4'' square feet for the table have a somewhat similar story (connected/disconnected from the table without any visible mounting gear)

The bubinga wood has been resting for the last 15 years, ~€2200 at the current price level per cubic meter.

(pics on request)

Last edited:

The bubinga wood has been resting for the last 15 years, ~€2200 at the current price level per cubic meter.

(pics on request)

This guy had a table for you...

https://www.etsy.com/listing/244831...98383d6ad8e1&gclid=CKrZhbjeoskCFUYWHwodgbAFDQ

Thanks, I appreciate the useful ideas. I salvaged some. I weighted a piece over night to true it up. On a flat surface placing ply and a couple 10lb barbell plates on it. Then screwed and glued some hardwood strips to the underside. Hopefully it will stay put because plans are a surface for a stainless steel tube amplifier, that should display nice.

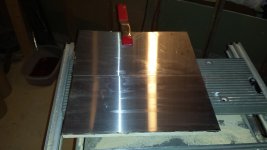

I prefer cutting the steel outside in the natural light, but falling snow didn't allow me that option. Thats when screw ups like that can happen -->.

It was the first pass, it MIGHT of skidded off the felt ink line (Id rather blame that lol). I plan to re brush finish because it already has light scratches. But the gouge is just too deep to remove.

I prefer cutting the steel outside in the natural light, but falling snow didn't allow me that option. Thats when screw ups like that can happen -->.

It was the first pass, it MIGHT of skidded off the felt ink line (Id rather blame that lol). I plan to re brush finish because it already has light scratches. But the gouge is just too deep to remove.

Attachments

Here are a couple tables.... The beech I cut myself... Table is about 4' by 9' The cherry is solid leg sections with a top that has a cardboard honeycomb core.

Attachments

Excellent work! I particularly like the one displayed in pic#5 and the way you notched the legs where they meet the table top.

a top that has a cardboard honeycomb core.

That's not a table, it's an airplane part.

Why buy made junk at a stupid price level, with unflexible sizes, if one has to look at it for decades, I says.

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- bonding soft and hard woods together