Hello,

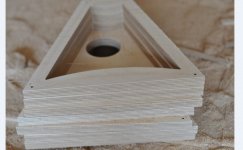

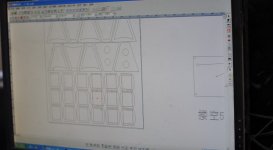

I'm pleased to develop a new series cabinet made by CNC machine. High precision processing of CNC machine is able to cut any shapes on plywood. This is my first sample of a bookshelf cabinet for CHR-70. The material selected is Finland WISA birch plywood.

I'm pleased to develop a new series cabinet made by CNC machine. High precision processing of CNC machine is able to cut any shapes on plywood. This is my first sample of a bookshelf cabinet for CHR-70. The material selected is Finland WISA birch plywood.

With a CNC would it not be easy and better to NOT use right angles for the internal cavity so as to avoid parallel walls and the resulting standing waves?

I am liking that a lot! I've never made any speakers, but if and when I do, I will use that method.

The result of the unfinished or varnished ply will look very restrained and Scandinavian, or you can presumably veneer it. I'm almost tempted to start straight away...

The result of the unfinished or varnished ply will look very restrained and Scandinavian, or you can presumably veneer it. I'm almost tempted to start straight away...

Hi henry,

I want to try something special.

Thanks,

Tony.

I want to try something special.

Thanks,

Tony.

great news, im sure u will try some wild imagination soon 😀

cheers

henry

Hi Charles,

Thanks for your remind. I want to keep the internal volume unchanged as Till 70's. I will put damping material into the cabinet.

Tony.

Thanks for your remind. I want to keep the internal volume unchanged as Till 70's. I will put damping material into the cabinet.

Tony.

With a CNC would it not be easy and better to NOT use right angles for the internal cavity so as to avoid parallel walls and the resulting standing waves?

Hi Charles,

Thanks for your remind. I want to keep the internal volume unchanged as Till 70's. I will put damping material into the cabinet.

Tony.

Asymmetrical "Wavy" walls would be the way to go... Just as easy but mobedda.

While you are considering changes... why not implement at least three holes in each piece in the same spot that could be used to align all of them. For instance, you could put a threaded rod through these holes to align the pieces and clamp them together while gluing the stack together...

Also, +1 on not using parallel, rectilinear inside walls.

-Charlie

Also, +1 on not using parallel, rectilinear inside walls.

-Charlie

Hi Charlie,

Thanks for your recommendation. That is possible to do like this.

Thanks,

Tony.

Thanks for your recommendation. That is possible to do like this.

Thanks,

Tony.

While you are considering changes... why not implement at least three holes in each piece in the same spot that could be used to align all of them. For instance, you could put a threaded rod through these holes to align the pieces and clamp them together while gluing the stack together...

Also, +1 on not using parallel, rectilinear inside walls.

-Charlie

Attachments

Hi Guys,

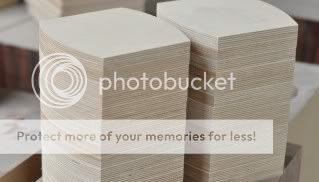

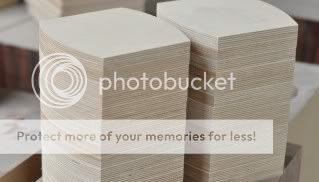

The panels in post #8 are my current reference speaker project. Great job machining by Tony.

The panels in post #8 are my current reference speaker project. Great job machining by Tony.

Hi henry,

Do you mean external corners?

Thanks,

Tony.

Do you mean external corners?

Thanks,

Tony.

hi tony,

how about the corners? those are sharp corners.

cheers

henry

Attachments

The finished speakers will be available later.

Thanks.

Thanks.

That looks cool, what do the finished speakers look like?

OK and thanks.

I am interested. Post a photo or design if you haveit ready. Thanks!

- Status

- Not open for further replies.

- Home

- More Vendors...

- Twin Audio

- Birch Plywood Cabinets made by CNC machine