this is a BASH based plate amp from an Athena AS-P6000 subwoofer and it basically seems like the power supply has some kind of problem. instead of music i get a buzzing, i would describe it as PWM at 120 hz proportional to the audio input level. based on what i have have heard about the power supply stage of these, for some reason it is not switching at the normal high frequency. nothing on the board looks toasted, and none of the joints look cold so i'm not sure what to do about it. the crossover has power, +- 15 volts. any suggestions on how to fix this? is it possible to rip out the fancy follower smps deal and throw a linear supply on this thing since it is really just AB? it seems like such a waste to throw it away and get a new/used, different/better amplifier

Attachments

I'm interested in following this. I have a smoked bash amp (Daniel -- boy genius next door -- says he could fix it if he had a schemo)

dave

dave

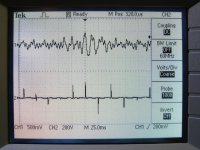

here is a scope shot,

CH1 is the signal i am giving it, it is some music through a subwoofer crossover, yes that is going into the crossover built into the amp, double crossover, oh my gawd, so bright, so vivid

CH2 is the speaker output. not very musical

i might try to cut the power rails between the SMPS and amp and power it with a linear psu

CH1 is the signal i am giving it, it is some music through a subwoofer crossover, yes that is going into the crossover built into the amp, double crossover, oh my gawd, so bright, so vivid

CH2 is the speaker output. not very musical

i might try to cut the power rails between the SMPS and amp and power it with a linear psu

Attachments

Hello Gentlemen, this is for a different brand of equipment (Klipsch), but they used the BASH technology in the amps. Here's a link to a reverse engineering job that was done on the Klipsch Promedia. They also have some good information about what seems to be a common failure, at least in the Klipsch design.

Klipsch Promedia V.2-400, V4.1, V2.1, And V5.1 Amplifier Repair

Peace,

Dave

P.S. I believe that at least one of the two individuals involved in the website and/or reverse engineering is a member here.

Klipsch Promedia V.2-400, V4.1, V2.1, And V5.1 Amplifier Repair

Peace,

Dave

P.S. I believe that at least one of the two individuals involved in the website and/or reverse engineering is a member here.

Orb Audio BASH Plate Amp Repair

There hasn’t been any activity on this thread for some time, but I thought someone attempting to repair a BASH plate subwoofer amplifier might benefit from my experience. The amp in question is an Orb Audio Super Eight 200 Watt plate amp provided with Orb’s Super Eight powered subwoofer. I bought the subwoofer in 2008 and used it for six years. In the summer of 2014 it started to get noisy; and the noise increased until it totally overwhelmed the desired bass signal, whereupon I ordered a replacement amp of the same model from Orb. As an electronics tinkerer/hobbyist, I decided to try to repair the faulty amp for use with a cobbled-together stereo system in my shop.

I was unsuccessful in locating any design information and/or circuit diagrams for the amp. The technical support folks at Orb were responsive, but indicated that the only known design information was in Chinese and couldn’t be released anyway due to patent considerations. I then decided to just start poking around inside the amp to see if I could spot the problem.

My first stab was to replace the big electrolytic capacitors in the power-supply section of the main board, since a component of the observed noise seemed to be 60-Hz hum. Replacement of these capacitors seemed to reduce the hum-portion of the noise, but the main component - a white-noise “rush” sound - remained. One of the characteristics of the noise was that it was barely noticeable immediately after turning on the amp, but grew in volume until after about 5 minutes or so when it completely obliterated the program material. This suggested that the noise was due to a thermal effect. I obtained some “Component Cooler” from Radio Shack and, while the amp was turned on, proceeded to squirt the coolant on the output power transistors, and any other component that had a visible heat sink tab, to momentarily cool down each component one by one. The “Eureka Moment” occurred when I squirted the components labeled U4 and U5 on the PCB. These turned out to be voltage regulators: U4 a L7815CV, and U5 a L7915CV. See Figure 1. The amp noise disappeared immediately after each voltage regulator was cooled; the noise then returned a minute or so later after the component heated up. I ordered the replacement voltage regulators from Mouser for about 68 cents apiece, installed them, and now the amp is again operational.

Painful Lessons Learned: This amp is obviously designed NOT to be repaired. Be very careful when desoldering components. There are very fragile hair-width wiring paths imbedded on the top side of the PCB under a thin layer of varnish/plastic that can be easily pulled out or broken if you are not careful when desoldering and removing the faulty components (Painful Lesson #1). I would recommend purchasing a good desoldering tool (e.g., OK Industries DP-200, approx. $24 from Mouser) if you do not already have one. Use a small pencil iron with needle tip for all soldering work. I decided to install heat sinks on the new voltage regulators to extend their lives beyond the six-year life of the originals. (I found that the manufacturer began using heat sinks on these components in later versions of the Super Eight amp). I used some scrap aluminum sheet I had on hand for the heat sinks. See Figure 2. DO NOT sink both these components together with a single piece of conducting material. These regulators are complementary: the L7815CV is designed for +15 V output and the L7915CV is designed for -15V output. Electrically connecting their tabs together will destroy both regulators and take down other components in the amp as soon as power is applied (Painful Lesson #2).

Summary: Hopefully, anyone with a Super Eight amp that failed in a similar manner to mine will find my experience helpful in repairing his/her amp. The following general suggestions are provided for anyone attempting to repair other similar digital amps in the absence of design/circuit-diagram information: 1) Try the simple stuff first. Closely examine all components under a strong desk lamp and magnifying glass for signs of burn-out/malfunction, e.g., discoloration, bloating. This approach was helpful in resolution of Painful Lesson #2 above. 2) Replace the major electrolytic capacitors as a matter of course. These components tend to wear out over time, and are fairly inexpensive. 3) In instances of thermal-related soft failure, as in the case above, use an aerosol component cooler as described above to isolate the faulty component(s).

There hasn’t been any activity on this thread for some time, but I thought someone attempting to repair a BASH plate subwoofer amplifier might benefit from my experience. The amp in question is an Orb Audio Super Eight 200 Watt plate amp provided with Orb’s Super Eight powered subwoofer. I bought the subwoofer in 2008 and used it for six years. In the summer of 2014 it started to get noisy; and the noise increased until it totally overwhelmed the desired bass signal, whereupon I ordered a replacement amp of the same model from Orb. As an electronics tinkerer/hobbyist, I decided to try to repair the faulty amp for use with a cobbled-together stereo system in my shop.

I was unsuccessful in locating any design information and/or circuit diagrams for the amp. The technical support folks at Orb were responsive, but indicated that the only known design information was in Chinese and couldn’t be released anyway due to patent considerations. I then decided to just start poking around inside the amp to see if I could spot the problem.

My first stab was to replace the big electrolytic capacitors in the power-supply section of the main board, since a component of the observed noise seemed to be 60-Hz hum. Replacement of these capacitors seemed to reduce the hum-portion of the noise, but the main component - a white-noise “rush” sound - remained. One of the characteristics of the noise was that it was barely noticeable immediately after turning on the amp, but grew in volume until after about 5 minutes or so when it completely obliterated the program material. This suggested that the noise was due to a thermal effect. I obtained some “Component Cooler” from Radio Shack and, while the amp was turned on, proceeded to squirt the coolant on the output power transistors, and any other component that had a visible heat sink tab, to momentarily cool down each component one by one. The “Eureka Moment” occurred when I squirted the components labeled U4 and U5 on the PCB. These turned out to be voltage regulators: U4 a L7815CV, and U5 a L7915CV. See Figure 1. The amp noise disappeared immediately after each voltage regulator was cooled; the noise then returned a minute or so later after the component heated up. I ordered the replacement voltage regulators from Mouser for about 68 cents apiece, installed them, and now the amp is again operational.

Painful Lessons Learned: This amp is obviously designed NOT to be repaired. Be very careful when desoldering components. There are very fragile hair-width wiring paths imbedded on the top side of the PCB under a thin layer of varnish/plastic that can be easily pulled out or broken if you are not careful when desoldering and removing the faulty components (Painful Lesson #1). I would recommend purchasing a good desoldering tool (e.g., OK Industries DP-200, approx. $24 from Mouser) if you do not already have one. Use a small pencil iron with needle tip for all soldering work. I decided to install heat sinks on the new voltage regulators to extend their lives beyond the six-year life of the originals. (I found that the manufacturer began using heat sinks on these components in later versions of the Super Eight amp). I used some scrap aluminum sheet I had on hand for the heat sinks. See Figure 2. DO NOT sink both these components together with a single piece of conducting material. These regulators are complementary: the L7815CV is designed for +15 V output and the L7915CV is designed for -15V output. Electrically connecting their tabs together will destroy both regulators and take down other components in the amp as soon as power is applied (Painful Lesson #2).

Summary: Hopefully, anyone with a Super Eight amp that failed in a similar manner to mine will find my experience helpful in repairing his/her amp. The following general suggestions are provided for anyone attempting to repair other similar digital amps in the absence of design/circuit-diagram information: 1) Try the simple stuff first. Closely examine all components under a strong desk lamp and magnifying glass for signs of burn-out/malfunction, e.g., discoloration, bloating. This approach was helpful in resolution of Painful Lesson #2 above. 2) Replace the major electrolytic capacitors as a matter of course. These components tend to wear out over time, and are fairly inexpensive. 3) In instances of thermal-related soft failure, as in the case above, use an aerosol component cooler as described above to isolate the faulty component(s).

Attachments

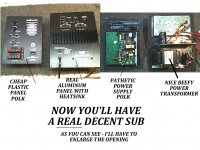

It seems that many, if not all of those plate amps today are using an SMPS supply, and cheap build quality - and fail prematurely.

I recently had a Polk sub with those crappy plastic plate amps.

Out it came - ripped it out and installed a solid linear-powered 100W replacement from Apex Jr.

The difference was amazing - a "real" 100W sound, not that crappy fake junk.

I recently had a Polk sub with those crappy plastic plate amps.

Out it came - ripped it out and installed a solid linear-powered 100W replacement from Apex Jr.

The difference was amazing - a "real" 100W sound, not that crappy fake junk.

Attachments

Last edited:

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- BASH amplifier problem