Hey all. I’m new to this forum and I’ve never built a speaker before but am trying my hand at it. I’d appreciate thoughts feedback or suggestions for improvement on a BW Nautilus inspired full range driver project I’m working on. Here are the design elements I have so far:

- To keep it simple(er), I’m going with a single full range driver design. Leaning towards Mark Audio MAOP 10 or TB W6-1916

- Sealed exponentially tapered tube tuned to address frequencies down to 60 hz (will use JL Audio CR1 to cross to dual JL Audio E112 subs probably around 100-120 hz or so… I want the tube tuned to 60hz for flexibility in the crossover frequency should I need it).

- the real nautilus uses fiberglass reinforced ABS with 10 mm walls. I’ll be 3D printing this (in pieces) using carbon fiber reinforced polycarbonate and the walls will be 15-20 mm thick but also be hollow so I can fill them with sand for dampening.

- the tapered tube will have progressively denser filler from opening to back tip

- I’m using chatGPTo1 to do the calculations for me.

I’d appreciate any thoughts, suggestions, or feedback.

- To keep it simple(er), I’m going with a single full range driver design. Leaning towards Mark Audio MAOP 10 or TB W6-1916

- Sealed exponentially tapered tube tuned to address frequencies down to 60 hz (will use JL Audio CR1 to cross to dual JL Audio E112 subs probably around 100-120 hz or so… I want the tube tuned to 60hz for flexibility in the crossover frequency should I need it).

- the real nautilus uses fiberglass reinforced ABS with 10 mm walls. I’ll be 3D printing this (in pieces) using carbon fiber reinforced polycarbonate and the walls will be 15-20 mm thick but also be hollow so I can fill them with sand for dampening.

- the tapered tube will have progressively denser filler from opening to back tip

- I’m using chatGPTo1 to do the calculations for me.

I’d appreciate any thoughts, suggestions, or feedback.

How big is your printer ?

How many kg of material do you need ?

(Currently 30€/kg)

How long are you willing to wait for the printing ?

Check this out :

https://3dprint.com/5188/akemake-first-3d-printed-wood-speaker/

Patrick

How many kg of material do you need ?

(Currently 30€/kg)

How long are you willing to wait for the printing ?

Check this out :

https://3dprint.com/5188/akemake-first-3d-printed-wood-speaker/

Patrick

This will be a fun project. A WAW to end all WAW's.

I think the Nautilus had a cone behind the magnet of the midrange drivers. Make sure to print that too and also fill it with sand.

I think the Nautilus had a cone behind the magnet of the midrange drivers. Make sure to print that too and also fill it with sand.

To print the 4 inch as linked above and add a tweeter as a mini Nautilus 2-way is a more realistic DIY project.

Still takes 20 hours to print one.

But at least can fit the normal printer volume.

Patrick

Still takes 20 hours to print one.

But at least can fit the normal printer volume.

Patrick

I’m using a Bambu P1S with aftermarket diamond hot end that can print abrasive filament (it’s about $150 piece so not prohibitively expensive). That printer can print up to 256x256 mm so this print will be segmented into parts. Part of why I chose PC-CF is because it glues very well. I was initially going to use a different filament but it didn’t glue up well so it’d be hard to assemble. I plan to create rabbet joints (or something similar) to facilitate alignment and gluing of the parts. I’ll likely design in some tabs to screw together to help with glue clamping.How big is your printer ?

How many kg of material do you need ?

(Currently 30€/kg)

How long are you willing to wait for the printing ?

Check this out :

https://3dprint.com/5188/akemake-first-3d-printed-wood-speaker/

Patrick

In terms of how long I plan to wait for printing: as long as it takes. I don’t care about print times.

And yes PC-CF is one of the more expensive filaments. I’d like to use PolyX at about $130/kg. Each cabinet should be ~3kg so roughly $400 in filament.

I’m not sure I understand. Can you elaborate? Or do you have a link to a document I can look at?This will be a fun project. A WAW to end all WAW's.

I think the Nautilus had a cone behind the magnet of the midrange drivers. Make sure to print that too and also fill it with sand.

Thank you for this link! I’ll review it more closely when I have a min.

Two general suggestions, FWIW:

- Make sure your selected driver is capable of 60Hz in a sealed box enclosure. They don't function in quite the same way as a sealed TL, but as far as the viable loading BW is concerned they're more or less the same. And

- ChatGPT is incapable of designing a quality TL, so I would avoid using it as a source for design.

fair point on the on the 60hz extension.

Why do you say it’s incapable? Do you have a piece of software you’d suggest instead that a newb can utilize? I’d also likely just post the design ChatGPT cooks up to see what people think.

Why do you say it’s incapable? Do you have a piece of software you’d suggest instead that a newb can utilize? I’d also likely just post the design ChatGPT cooks up to see what people think.

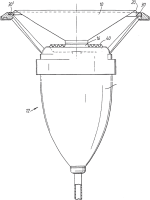

I'm sorry, it was the 800/801 that had the 'jet engine' midrange enclosure.I’m not sure I understand. Can you elaborate? Or do you have a link to a document I can look at?

Attachments

What’s a WAW?This will be a fun project. A WAW to end all WAW's.

I think the Nautilus had a cone behind the magnet of the midrange drivers. Make sure to print that too and also fill it with sand.

- Home

- Loudspeakers

- Full Range

- B&W Nautilus Inspired Full Range Speaker Project