Just an idle idea, and I was wandering if it has been done already.

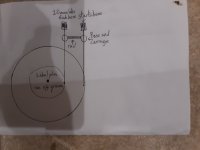

Simply, using the average time of an lp side, say 20 minutes. Then moving the tonearm base (with a constant speed motor) to maintain approximate linear tracking.

This would be a very simple thing to make (true linear trackers are always incredibly complex) and could be structurally very sound. It could even perhaps use an existing favourite tonearm.

Is there an intrinsic fault in this idea that I have missed?

Simply, using the average time of an lp side, say 20 minutes. Then moving the tonearm base (with a constant speed motor) to maintain approximate linear tracking.

This would be a very simple thing to make (true linear trackers are always incredibly complex) and could be structurally very sound. It could even perhaps use an existing favourite tonearm.

Is there an intrinsic fault in this idea that I have missed?

Attachments

Last edited by a moderator:

The one you were talking about is completely different from midrange's proposal.

I think midrange's proposal may work. It was mentioned by Conrad Hoffman a long time ago.

"80mm travel in 20mins is the assumption, based on the average of 30 records I measured at random. Standard Deviation was 13.6mm. ( ie 68% of records were within +/- 13.6mm over 20mins). Travel of the arm pivot vs travel of the stylus across the record is non linear, but is corrected by a cam on the clock tape feed." (From the site)

Why is this "completely different"? You did not read it, I suppose.

Why is this "completely different"? You did not read it, I suppose.

Last edited by a moderator:

Look at the diagrams. What are you talking about? Are they the same? You DO NOT know what you were talking about. In fact, I didn't further check if the geometry is correct or not. I suspect that the geometry for the 12" arm will have large tracking errors.

Last edited:

My thoughts about Hoffman's proposal. I called it Hoffman's proposal because he was the first one, as I know, to mention such a proposal.

1. Starting position. The records don't have exactly the same position to start. If the position of starting point for a record is shorter than the starting point of the arm in 1 mm, there will be about .25 degrees tracking errors across the surface of the record for a 9" arm.

2. Eccentricity. If the eccentricity is about 1 mm, there will be .25 degrees tracking errors across the surface of the record for a 9" arm.

All the problems above can be solved by a passive linear arm because a passive linear arm will correct its positions by itself.

1. Starting position. The records don't have exactly the same position to start. If the position of starting point for a record is shorter than the starting point of the arm in 1 mm, there will be about .25 degrees tracking errors across the surface of the record for a 9" arm.

2. Eccentricity. If the eccentricity is about 1 mm, there will be .25 degrees tracking errors across the surface of the record for a 9" arm.

All the problems above can be solved by a passive linear arm because a passive linear arm will correct its positions by itself.

Hi midrange,

No doubt your tone arm would work. But it seems to me that it would have larger tracking errors than a conventional pivoting tone arm with zero tracking error at the null points. I haven't done the math, so I could be wrong.

Sincerely,

Ralf

No doubt your tone arm would work. But it seems to me that it would have larger tracking errors than a conventional pivoting tone arm with zero tracking error at the null points. I haven't done the math, so I could be wrong.

Sincerely,

Ralf

This midrange guy obviously doesn't know about or consider the fact that record grooves do not have a linear spiral leading to the center/end.

Thus to assume such things, a constant-speed simple motion of the arm will be severely out of alignment during play.

Because modulation differences due to louder or bass modulations can cause the cutter head to move faster inward at times, softer sounds would cause less movement - so it varies for every record.

That is why manufacturers chose things like visual-angle adjustment via photocell-I/R sensing.

Also, a disco type record, particularly a 12" 45RPM version, will have a substantially faster inward spiral than say, a classical 33RPM.

Give the idea up.

Thus to assume such things, a constant-speed simple motion of the arm will be severely out of alignment during play.

Because modulation differences due to louder or bass modulations can cause the cutter head to move faster inward at times, softer sounds would cause less movement - so it varies for every record.

That is why manufacturers chose things like visual-angle adjustment via photocell-I/R sensing.

Also, a disco type record, particularly a 12" 45RPM version, will have a substantially faster inward spiral than say, a classical 33RPM.

Give the idea up.

A combination of linear constant speed advancing of the arm base, and a pivoting arm mounted on this arm base would work, wouldn't it?

I just measured the record playing width, and it is more like 8cm, which would reduce the maximum error to nearer 3.3 degrees. It does seem that this idea has been thought of before.

Indeed, easily upto 10x or more for a 12" single. I've one such with a play time of just over 2 mins so the grooves are nearly 1mm apart!Also, a disco type record, particularly a 12" 45RPM version, will have a substantially faster inward spiral than say, a classical 33RPM.

Plus..... A 12 inch 45RPM disco single that I have also has a short play time, and 2/3's of the record is the fast spiral ending groove.Indeed, easily upto 10x or more for a 12" single. I've one such with a play time of just over 2 mins so the grooves are nearly 1mm apart!

A "fixed" speed linear arm would never be able to follow it to the label.

Not properly.A combination of linear constant speed advancing of the arm base, and a pivoting arm mounted on this arm base would work, wouldn't it?

Besides, linear-tracking straight arms already have horizontal pivots.

The "constant speed" approach is as previously mentioned, not a proper way to design this.

Much too sloppy that 3.3 degrees.I just measured the record playing width, and it is more like 8cm, which would reduce the maximum error to nearer 3.3 degrees. It does seem that this idea has been thought of before.

So that "thought" went out the window.

My Kenwood linear-tracker allows only a 0.2 degree of offset before it automatically re-aligns itself to "0" again.

Here's a perfect example of being too obsessed about playing a record.

Warning do not try this at home. 😆

Warning do not try this at home. 😆

This concept is not to be compared with a proper linear- tracker, with all it's complications for a diyer. My question is directed as a comparison with a standard pivoting arm. As the title says, APPROXIMATE.

Of course 12" singles etc will not work with it. Perhaps there would be some way that the carriage could be moved to an optimum position, the motor disengaged, and just used as a standard pivoting tonearm.

Wiseoldtech. I apologise for the quotes seeming to appear from you. This is the first time I have used the new system here for quotes, and for some reason they all appear to be from the first quoter. I just clicked on them, and gave my response. I will have to work out how to use it, or just reply to one quote per post.

Apologies again.

Of course 12" singles etc will not work with it. Perhaps there would be some way that the carriage could be moved to an optimum position, the motor disengaged, and just used as a standard pivoting tonearm.

Wiseoldtech. I apologise for the quotes seeming to appear from you. This is the first time I have used the new system here for quotes, and for some reason they all appear to be from the first quoter. I just clicked on them, and gave my response. I will have to work out how to use it, or just reply to one quote per post.

Apologies again.

Hi, "This midrange guy" 🙂 ,(true linear trackers are always incredibly complex)

If you were to build a tone arm as you suggest, you would have achieved about 90% of the work required to build such a tone arm.

The additional step to provide the servo electronics would be minor compared to the mechanical work that is required. I would use the phrase "time consuming" rather than "complex"

Sincerely,

Ralf

Hey midrange, I saw your post because it was next to mine in the new posts section.

I made an arm like this, it would be more than 10 years ago.

I'll tell you the story. I was living with 2 friends one an engineer and mad audio freak and the other, just mad who worked for a repair shop.

The engineer had some Japanese deck with a linear arm but he decided it was crap so we decided to make our own linear arm. Not much later he got a girlfriend and lost interest but he still helped me.

The basic version was an arm mechanism on a sled driven across the record. The mechanism looked a bit like the steering on a horse and cart.

The sled came from my other mad friend and was from a laser disc player. To get the slow sled speed we used a motorised volume control modified so that it could rotate continuously. By using a drive belt off the volume knob it was easy to change the gearing by changing the size of the knob.

If this sounds crazy it was but to get back to your idea the engineer expected that the drive motor voltage would need to be adjusted across the record.

But do you know what, we tried a lot of records and once the motor speed was dialled in for that record it did not need adjusting. Just remember that the arm mechanism did allow for some misalignment but I remember the engineer being quite surprised that we could use a constant speed across the record.

It was completely impractical because we still had to adjust the overall speed for each record.

Anyway it went no further because the engineer got married and the mad friend was killed in a car accident.

I think it was much more than 10 years ago because laser disc players were dinosaurs by then.

Cheers, mouse (who has been drinking)

I made an arm like this, it would be more than 10 years ago.

I'll tell you the story. I was living with 2 friends one an engineer and mad audio freak and the other, just mad who worked for a repair shop.

The engineer had some Japanese deck with a linear arm but he decided it was crap so we decided to make our own linear arm. Not much later he got a girlfriend and lost interest but he still helped me.

The basic version was an arm mechanism on a sled driven across the record. The mechanism looked a bit like the steering on a horse and cart.

The sled came from my other mad friend and was from a laser disc player. To get the slow sled speed we used a motorised volume control modified so that it could rotate continuously. By using a drive belt off the volume knob it was easy to change the gearing by changing the size of the knob.

If this sounds crazy it was but to get back to your idea the engineer expected that the drive motor voltage would need to be adjusted across the record.

But do you know what, we tried a lot of records and once the motor speed was dialled in for that record it did not need adjusting. Just remember that the arm mechanism did allow for some misalignment but I remember the engineer being quite surprised that we could use a constant speed across the record.

It was completely impractical because we still had to adjust the overall speed for each record.

Anyway it went no further because the engineer got married and the mad friend was killed in a car accident.

I think it was much more than 10 years ago because laser disc players were dinosaurs by then.

Cheers, mouse (who has been drinking)

The Rabco ST-4/5/6/7/8 arms all used this principle (by mechanical means, not electrical) and work very effectively.Just an idle idea, and I was wandering if it has been done already.

Simply, using the average time of an lp side, say 20 minutes. Then moving the tonearm base (with a constant speed motor) to maintain approximate linear tracking.

- Home

- Source & Line

- Analogue Source

- Approximate linear tracking arm idea.